A kind of production method of a series of taste grilled seaweed rolls and products thereof

A production method and taste technology, which is applied to the production method of a series of flavored roasted seaweed rolls and its products, can solve the problems of lack of new products, single shape of seasoned seaweed products, and insufficient variety of tastes, so as to achieve reduced residue scattering, beautiful appearance, Delicate taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

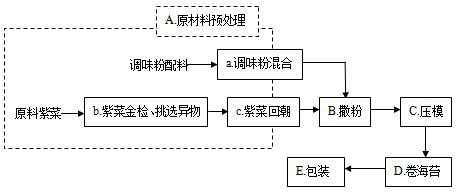

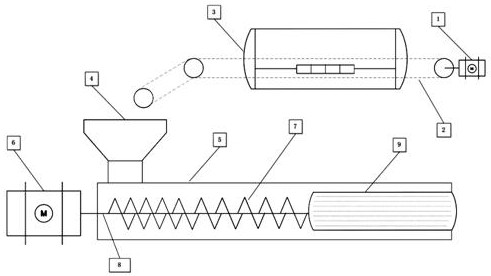

[0062] The automatic rolling production method of embodiment 1 original flavor seaweed roll product:

[0063] Mix refined iodized salt and white granulated sugar in a ratio of 1:6, and pulverize with a pulverizer (the mesh size of the pulverizer screen is 40 mesh), and then mix the pulverized mixture with glucose in a ratio of 1:1 in a mixer mix. After unpacking, put the once-processed laver with the glossy side up into the supply machine for delivery, and then pass through the metal detector and foreign object sorting machine to pick out metal and foreign objects, and collect them in the turnover box of the moisture regain box. Then put the dried laver in the frame into the moisture regain box for moisture regain. The temperature of the moisture regain box is controlled at 26 ℃, and the humidity is controlled at 85% for moisture regain. The specific moisture regain control needs to be combined with experience and rapid moisture analyzer testing. Turn on the flour spreader, u...

Embodiment 2

[0065] The automatic roll-forming production method of embodiment 2 spicy seaweed roll products:

[0066] Mix refined iodized salt and white granulated sugar in a ratio of 1:5, and pulverize with a pulverizer (the mesh size of the pulverizer is 38 mesh), and then mix the pulverized mixture with glucose in a ratio of 6:5 in a mixer mix. Unpack and take out the processed laver once, put it into the supply machine with the glossy side up for delivery, pass through the metal detector and foreign object sorting machine to sort out metal and foreign objects, and collect them in the turnover box of the moisture resurfacing box. Then put the dried laver in the frame into the moisture regain box for moisture regain. The temperature of the moisture regain box is controlled at 25 ℃, and the humidity is controlled at 83% for moisture regain. The control of the specific moisture regain needs to be combined with experience and rapid moisture analyzer testing. Turn on the flour spreader, us...

Embodiment 3

[0068] The automatic roll-forming production method of embodiment 3 seafood flavor seaweed roll products:

[0069] Mix refined iodized salt and white granulated sugar at a ratio of 2:11, and pulverize with a pulverizer (the mesh size of the pulverizer screen is 36 mesh), and then mix the pulverized mixture with glucose in a ratio of 12:11 in a mixer Mix to make seasoned powdered sugar; in addition, mix seafood powder and pepper powder in a ratio of 5:1, and mix them evenly in a mixer to make seasoned seafood powder. Unpack and take out the processed laver once, put it into the supply machine with the glossy side up for delivery, pass through the metal detector and foreign object sorting machine to sort out metal and foreign objects, and collect them in the turnover box of the moisture resurfacing box. Then put the dried laver in the box into the moisture regain box for moisture regain. The temperature of the moisture regain box is controlled at 27 ℃, and the humidity is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com