304 stainless steel roller and machining method

A 304 stainless steel, stainless steel tube technology, applied in the direction of rolls, metal processing equipment, metal rolling, etc., can solve the problems of easy to produce tearing cracks, end bending deformation, low weld toughness, etc., to avoid irreversible deformation, avoid The effect of bending and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

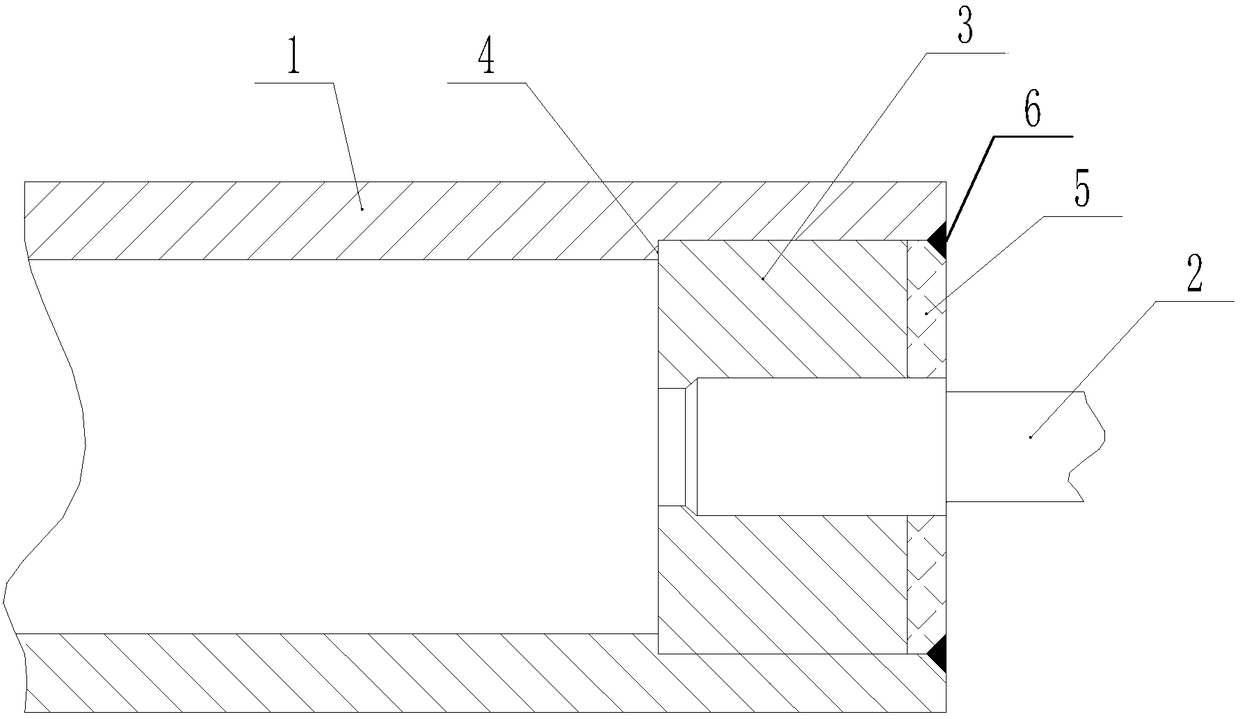

[0034] The present invention provides a 304 stainless steel roll, comprising a roll body 1, the interior of the roll body 1 is set as a hollow cavity, the roll body 1 penetrates a roll shaft 2 in the axial direction, and also includes a plug 3, a plug 3 It is fixedly connected with the inner wall of the roller body 1 and the outer wall of the roller shaft 2, and the plug 3 is made of gray cast iron.

[0035] As a further improvement of the present invention, a step platform 4 is arranged inside the roller body 1, and the plug 3 is fixed between the step platform 4 and the sealing plate 5 through the sealing plate 5, and the sealing plate 5 and the roller body 1 are welded by welding rods, and the sealing plate and A weld seam 6 is formed between the roller bodies 1 .

[0036] The present invention also provides a processing method for 304 stainless steel rolls, comprising the following steps:

[0037] S1: select the stainless steel tube to saw off, fix the length, grind and p...

Embodiment 2

[0048] The present invention provides a 304 stainless steel roll, comprising a roll body 1, the interior of the roll body 1 is set as a hollow cavity, the roll body 1 penetrates a roll shaft 2 in the axial direction, and also includes a plug 3, a plug 3 It is fixedly connected with the inner wall of the roller body 1 and the outer wall of the roller shaft 2, and the plug 3 is made of gray cast iron.

[0049] As a further improvement of the present invention, a step platform 4 is arranged inside the roller body 1, and the plug 3 is fixed between the step platform 4 and the sealing plate 5 through the sealing plate 5, and the sealing plate 5 and the roller body 1 are welded by welding rods, and the sealing plate and A weld seam 6 is formed between the roller bodies 1 .

[0050] The present invention also provides a processing method for 304 stainless steel rolls, comprising the following steps:

[0051] S1: select the stainless steel tube to saw off, fix the length, grind and p...

Embodiment 3

[0062] The present invention provides a 304 stainless steel roll, comprising a roll body 1, the interior of the roll body 1 is set as a hollow cavity, the roll body 1 penetrates a roll shaft 2 in the axial direction, and also includes a plug 3, a plug 3 It is fixedly connected with the inner wall of the roller body 1 and the outer wall of the roller shaft 2, and the plug 3 is made of gray cast iron.

[0063] As a further improvement of the present invention, a step platform 4 is arranged inside the roller body 1, and the plug 3 is fixed between the step platform 4 and the sealing plate 5 through the sealing plate 5, and the sealing plate 5 and the roller body 1 are welded by welding rods, and the sealing plate and A weld seam 6 is formed between the roller bodies 1 .

[0064] The present invention also provides a processing method for 304 stainless steel rolls, comprising the following steps:

[0065] S1: select the stainless steel tube to saw off, fix the length, grind and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com