Sludge low-temperature drying distributing system and distributing method

A material distribution system and mud material technology, which is applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of inaccessible, mud cannot be extruded and formed, and achieve the effect of not easy to block, convenient operation and maintenance, and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

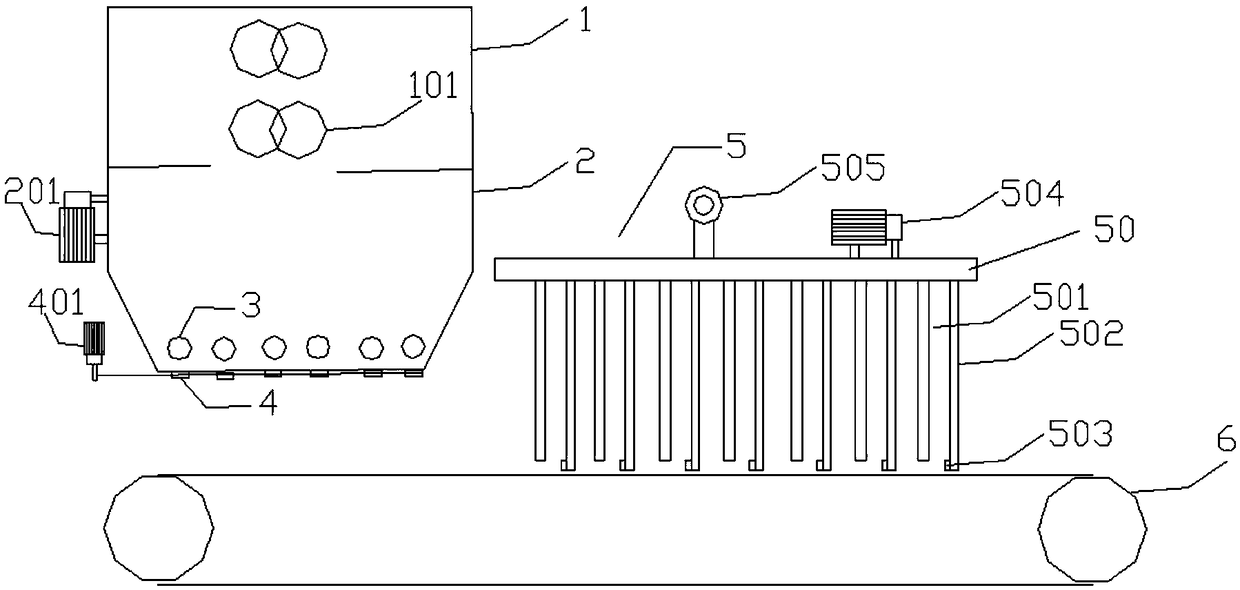

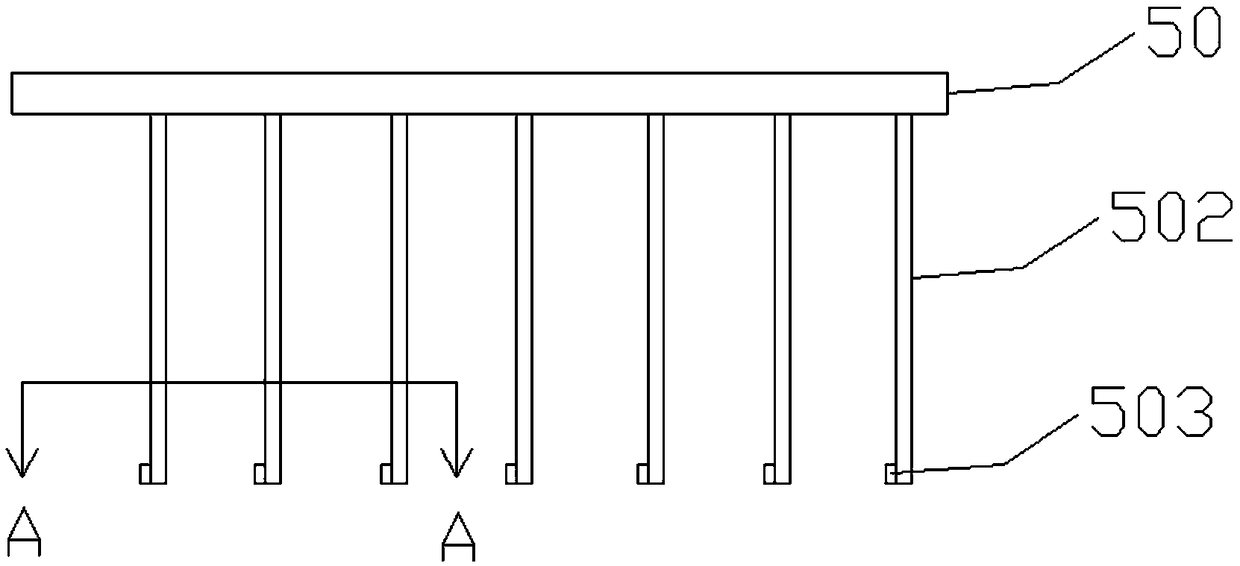

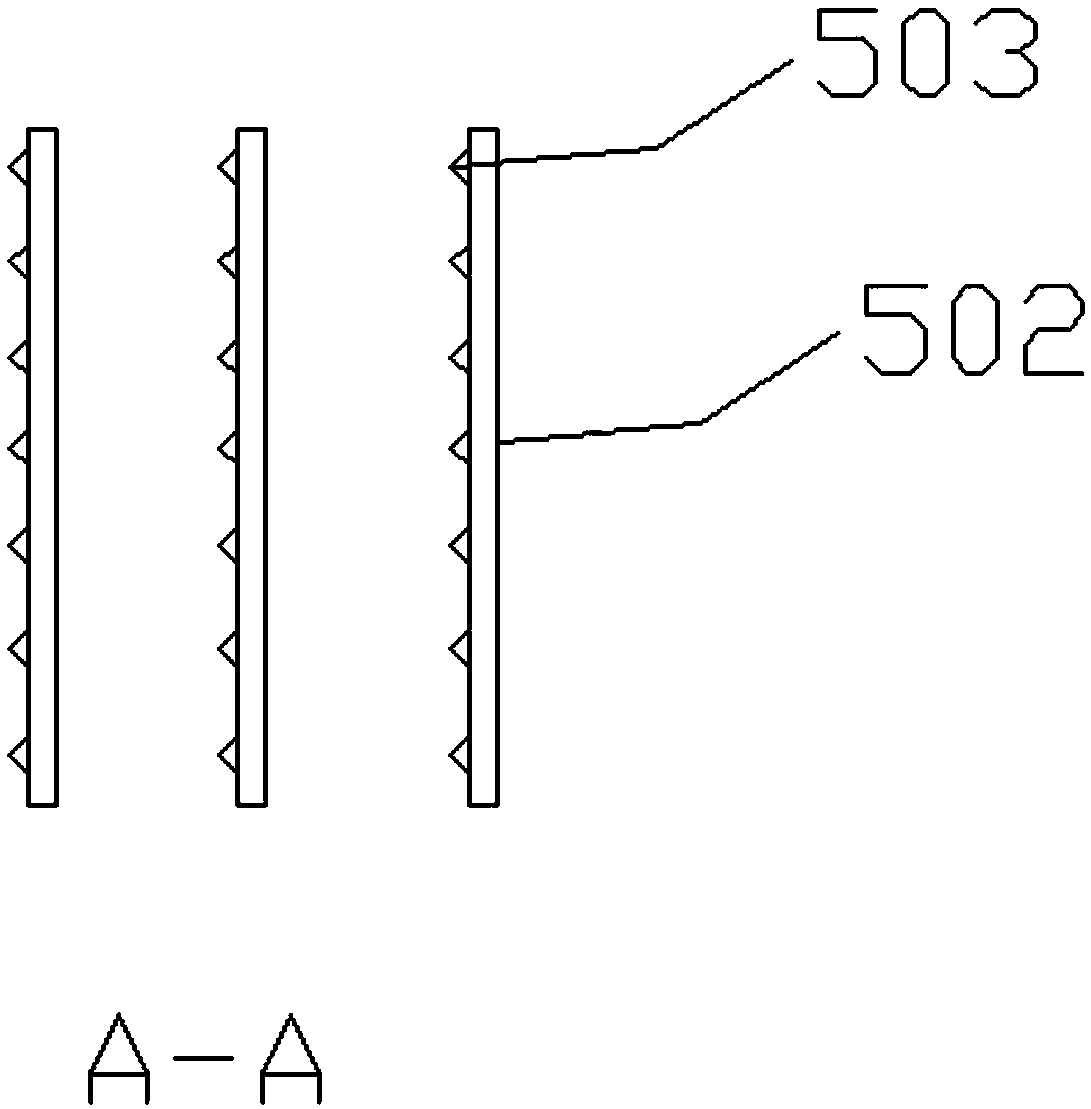

[0035] Such as figure 1 As shown, a sludge low-temperature drying distributing system of the present invention includes a mud cake crusher 1, a mud bin 2, a mud particle feeding screw 3, and a mud spreader 5; Cake crushing gear roller 101; mud cake crusher 1 is two-stage crushing, the first stage crushes the mud cake to less than 30mm, and the final crushing crushes the mud cake into mud particles with a particle size of ≦10mm; the mud bin 2 is located in the sludge Below the mud cake crushing gear roller 101 of the crusher.

[0036] The sludge crusher 1 is directly connected to the sludge outlet bin of the sludge deep removal system (that is, the sludge crusher 1 is connected to the mud cake bin at the outlet of the filter press of the sludge deep removal system, and the sludge cake is passed through The conveying equipment is transported from the mud cake bin at the mud outlet of the filter press to the sludge crusher inlet); the mud cake crushing gear roller 101 is fixed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com