Composite bulletproof material and preparation method thereof

A technology of composite materials and fabrics, which is applied in the field of composite bulletproof materials and its preparation, can solve the problems of decreased protective performance and achieve the effects of high sliding performance, good impact resistance and high shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

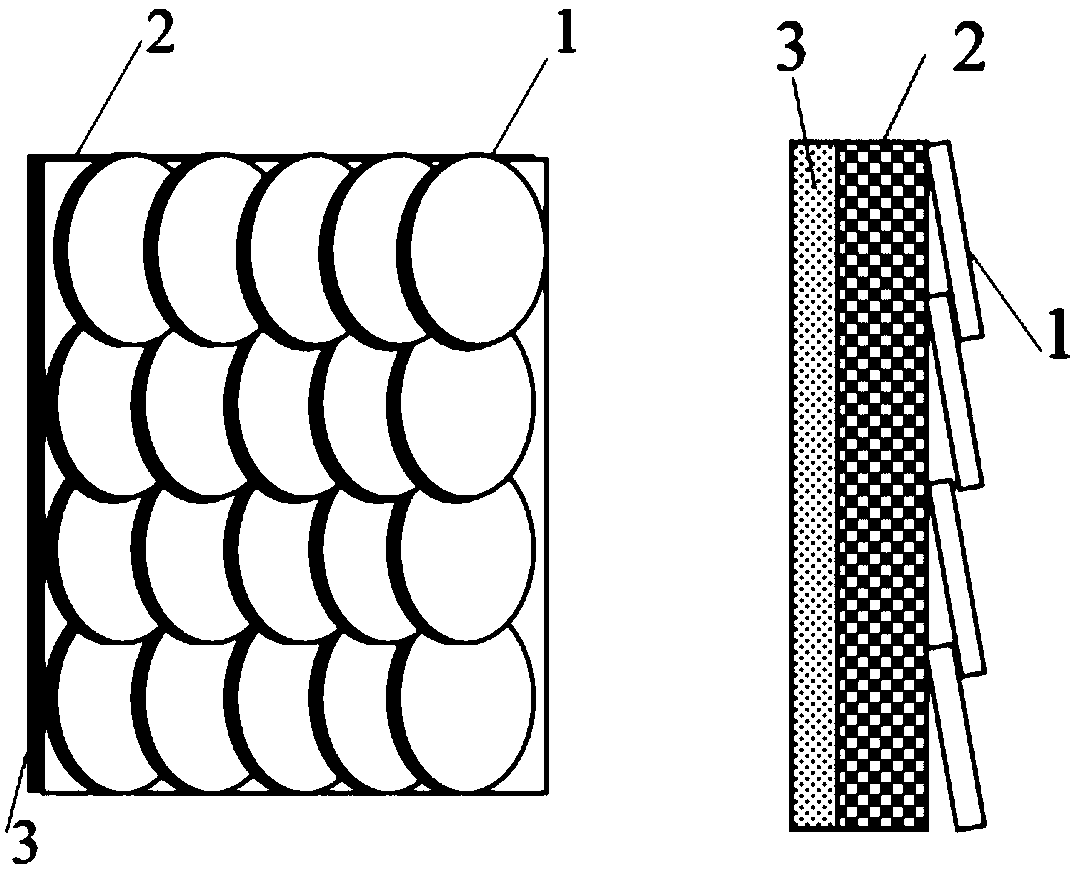

[0030] The aluminum sheet / Kevlar fabric / STF impregnated Kevlar fabric composite bulletproof material of the present invention, the surface layer is made of aluminum sheet, the thickness is 1.5mm, and the nail plate structure is used for laying, the middle layer fabric is 4 layers of Kevlar fabric, and the fiber linear density of the fabric is 93TEX. The density is 10.5×10.5 strands / cm, and the weight of the fabric is 201g / m 2 , the bottom layer is 2 layers of STF impregnated Kevlar fabric. STF (shear thickening fluid) is prepared by dispersing nano silicon dioxide in polyethylene glycol, the mass fraction of silicon dioxide is 30%, the viscosity after thickening reaches 1000 Pa.s, and the increase of STF is 50%.

[0031] The preparation method of aluminum sheet / Kevlar fabric / STF impregnated Kevlar fabric composite bulletproof material of the present invention:

[0032] Preparation of STF: Add nano-silica to polyethylene glycol gradually by means of mechanical dispersion, and ...

Embodiment 2

[0040] The 2 layers of Kevlar fabrics impregnated with STF as the bottom layer in Example 1 are replaced by 2 layers of pure Kevlar fabrics, and the surface layer is not covered with aluminum sheets, that is, only 6 layers of pure Kevlar fabrics are used to make Kevlar fabric composite bulletproof materials, and put into Infiltrate into a fabric bag for airtight packaging.

Embodiment 3

[0042] The 4 layers of pure Kevlar fabrics used as the middle layer in Example 1 are replaced by 4 layers of STF-impregnated Kevlar fabrics, and the surface layer is not covered with aluminum sheets, that is, only 6 layers of STF-impregnated Kevlar fabrics are used, and the STF-impregnated Kevlar fabric composite bulletproof material , into impermeable fabric bags for airtight packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Fiber linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com