Anti-aging rubber sealing ring material and preparation method thereof

A rubber sealing ring, anti-aging technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor anti-aging performance of rubber sealing rings, easy bonding of sealing rings with metal parts, and poor mechanical properties. To achieve the effect of enhancing the resistance to pressure change and anti-aging performance, easy to implement, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

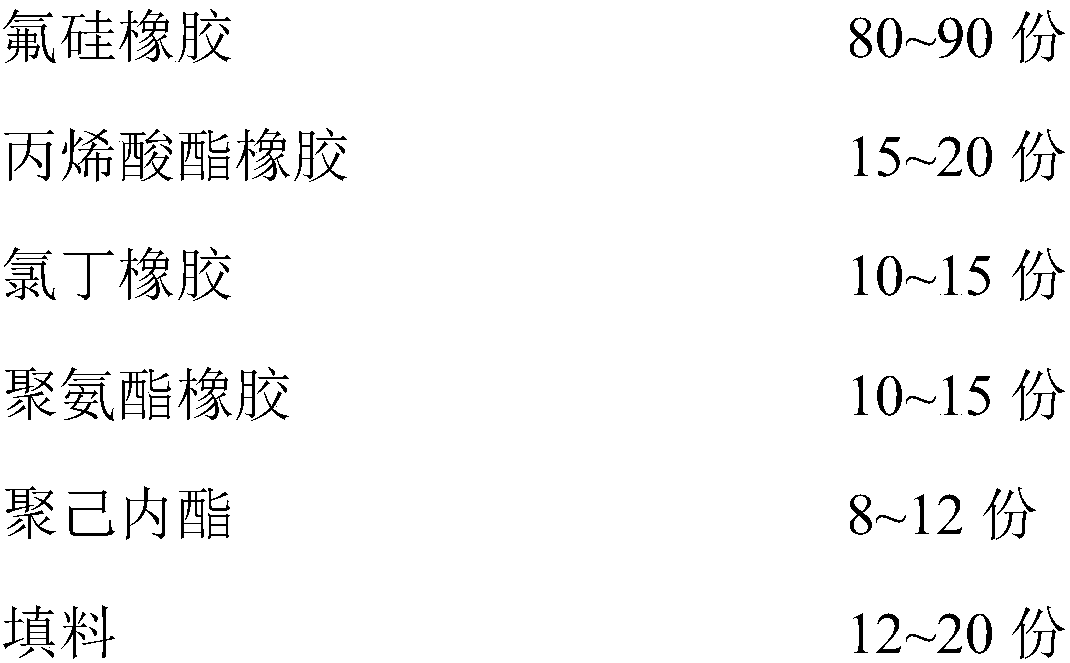

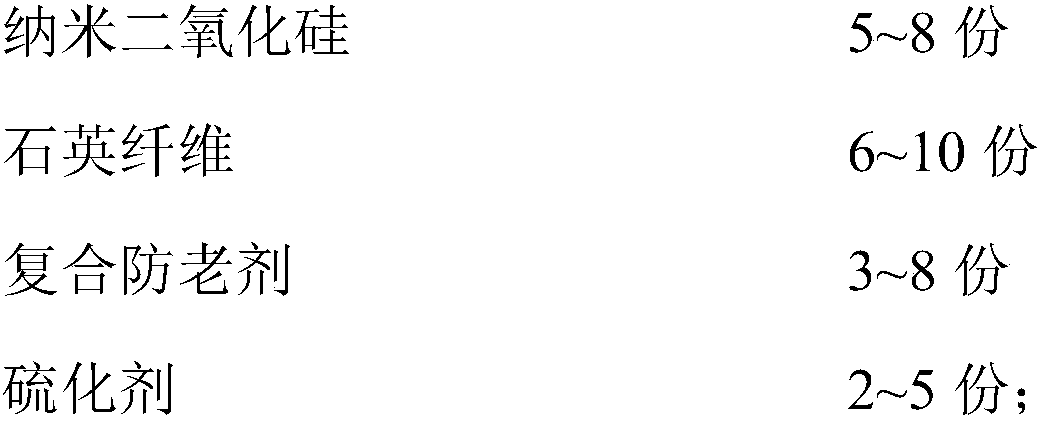

[0025] An anti-aging rubber sealing ring material and a preparation method thereof, wherein the anti-aging rubber sealing ring material is prepared from the following raw materials in parts by mass:

[0026]

[0027]

[0028] The preparation method of described anti-aging rubber sealing ring material comprises the following steps:

[0029] Step 1, weighing of raw materials: carry out weighing of each raw material component according to the above-mentioned mass parts;

[0030] Step 2, pretreatment of raw materials: plasticizing polyurethane rubber on an open mill, adding polycaprolactone evenly when the thickness of the plasticizing rubber material reaches 0.6mm, mixing evenly at 65°C, and obtaining the rubber material for use;

[0031] Step 3, preparation of the premix: first mix fluorosilicone rubber, acrylate rubber, neoprene rubber and the rubber obtained in step 2 on the mixer evenly, and the mixing temperature is 110°C, then add fillers, nano Silica, quartz fiber c...

Embodiment 2

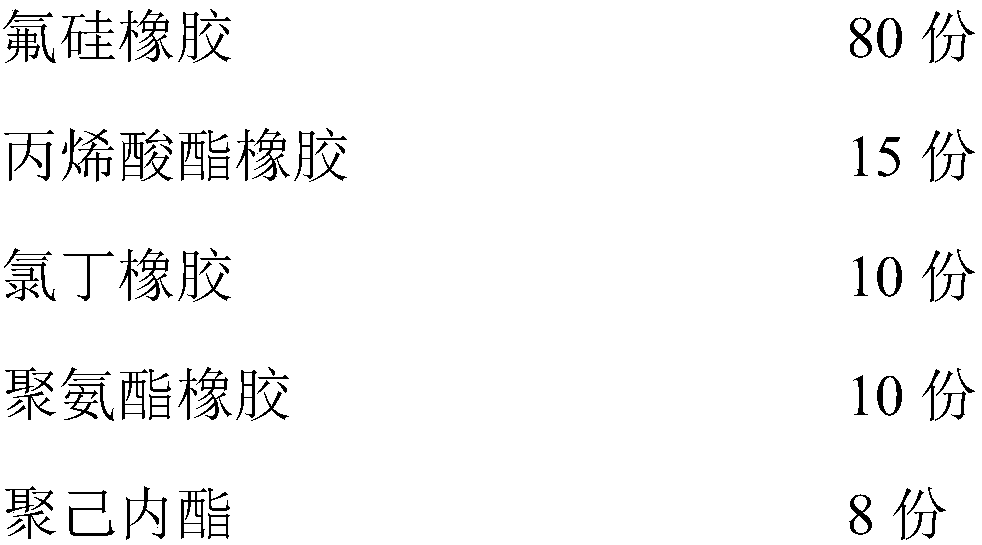

[0040] An anti-aging rubber sealing ring material and a preparation method thereof, wherein the anti-aging rubber sealing ring material is prepared from the following raw materials in parts by mass:

[0041]

[0042] The preparation method of described anti-aging rubber sealing ring material comprises the following steps:

[0043] Step 1, weighing of raw materials: carry out weighing of each raw material component according to the above-mentioned mass parts;

[0044] Step 2, pretreatment of raw materials: masticating polyurethane rubber on an open mill, adding polycaprolactone evenly when the thickness of the masticated rubber material reaches 0.8mm, mixing evenly at 75°C, and obtaining the rubber material for use;

[0045] Step 3, preparation of the premix: first mix fluorosilicone rubber, acrylate rubber, neoprene rubber and the rubber obtained in step 2 on the mixer evenly, and the mixing temperature is 115°C, then add fillers, nano Silica, quartz fiber continue mixing ...

Embodiment 3

[0054] An anti-aging rubber sealing ring material and a preparation method thereof, wherein the anti-aging rubber sealing ring material is prepared from the following raw materials in parts by mass:

[0055]

[0056]

[0057] The preparation method of described anti-aging rubber sealing ring material comprises the following steps:

[0058] Step 1, weighing of raw materials: carry out weighing of each raw material component according to the above-mentioned mass parts;

[0059]Step 2, pretreatment of raw materials: Plasticizing polyurethane rubber on an open mill, adding polycaprolactone evenly when the thickness of the plasticizing rubber material reaches 1.2mm, mixing evenly at 85°C, and obtaining the rubber material for use;

[0060] Step 3, preparation of the premix: first mix fluorosilicone rubber, acrylate rubber, chloroprene rubber and the rubber obtained in step 2 on the mixer evenly, and the mixing temperature is 120°C, then add fillers, nano Silica, quartz fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com