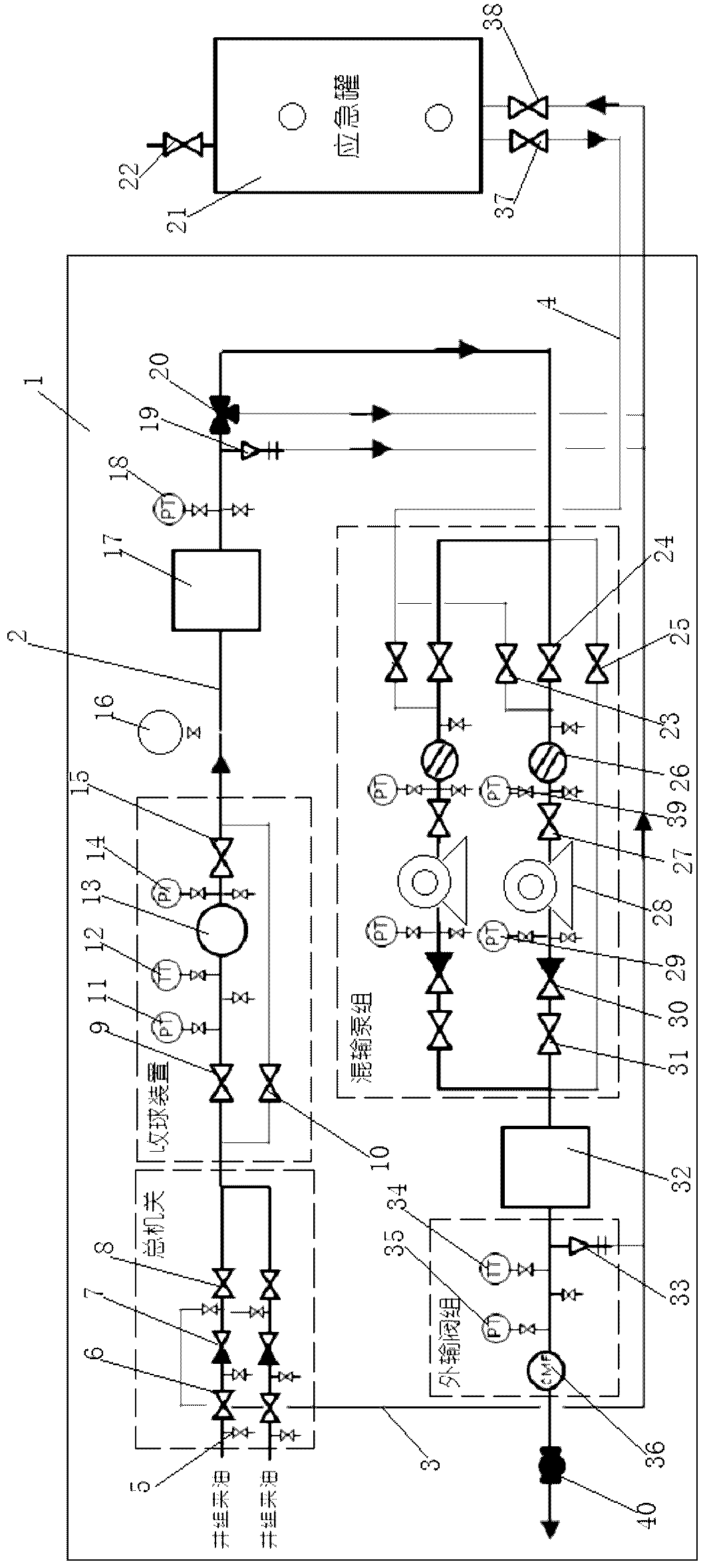

Skid-mounted oil and gas mixing and conveying device

A technology of oil and gas mixed transportation and mixed transportation, which is applied in the direction of gas/liquid distribution and storage, pipeline system, mechanical equipment, etc. It can solve the problems of high cost and meaningless gas-liquid separation function of buffer tanks, etc., to simplify the process flow and reduce the The effect of work intensity and risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] There are currently 123 stations in an oilfield with a liquid volume of less than 120 m3, and 49 stations (23%) have a daily liquid volume of less than 60 m3 3 , the operation efficiency of the site is low, the management is difficult, and the safety risk is high; the second is that with the continuous development of the low-cost strategy of the oil field, the number of oil and water wells continues to increase, and the comprehensive labor of single wells continues to decrease, it is necessary to optimize and simplify the ground The technological process, on the basis of safety and environmental protection, vigorously carry out unattended construction, and finally achieve the goal of reducing staff and increasing efficiency.

[0064] The one-time investment of the traditional booster station is about 2 million, covering an area of 2000m 2 . The skid-mounted oil-gas mixed transportation device of the present invention is used to transform the original site. The invest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com