Device and method for accurately measuring dead point on crankshaft of diesel engine

An accurate measurement, diesel engine technology, used in measurement devices, electrical devices, internal combustion engine testing, etc., can solve the problems of time-consuming and laborious operation, poor measurement accuracy, etc., to achieve high efficiency, improve quality and production efficiency, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

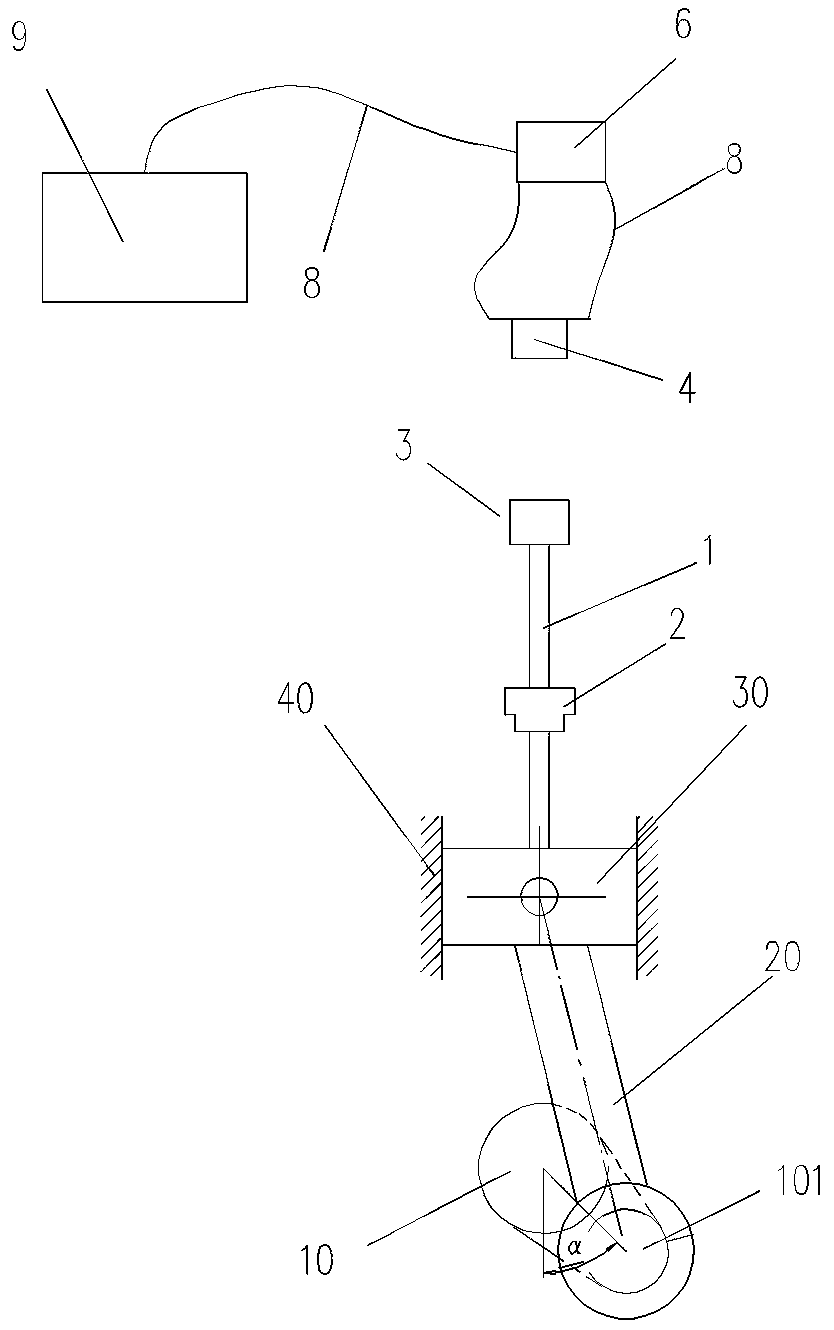

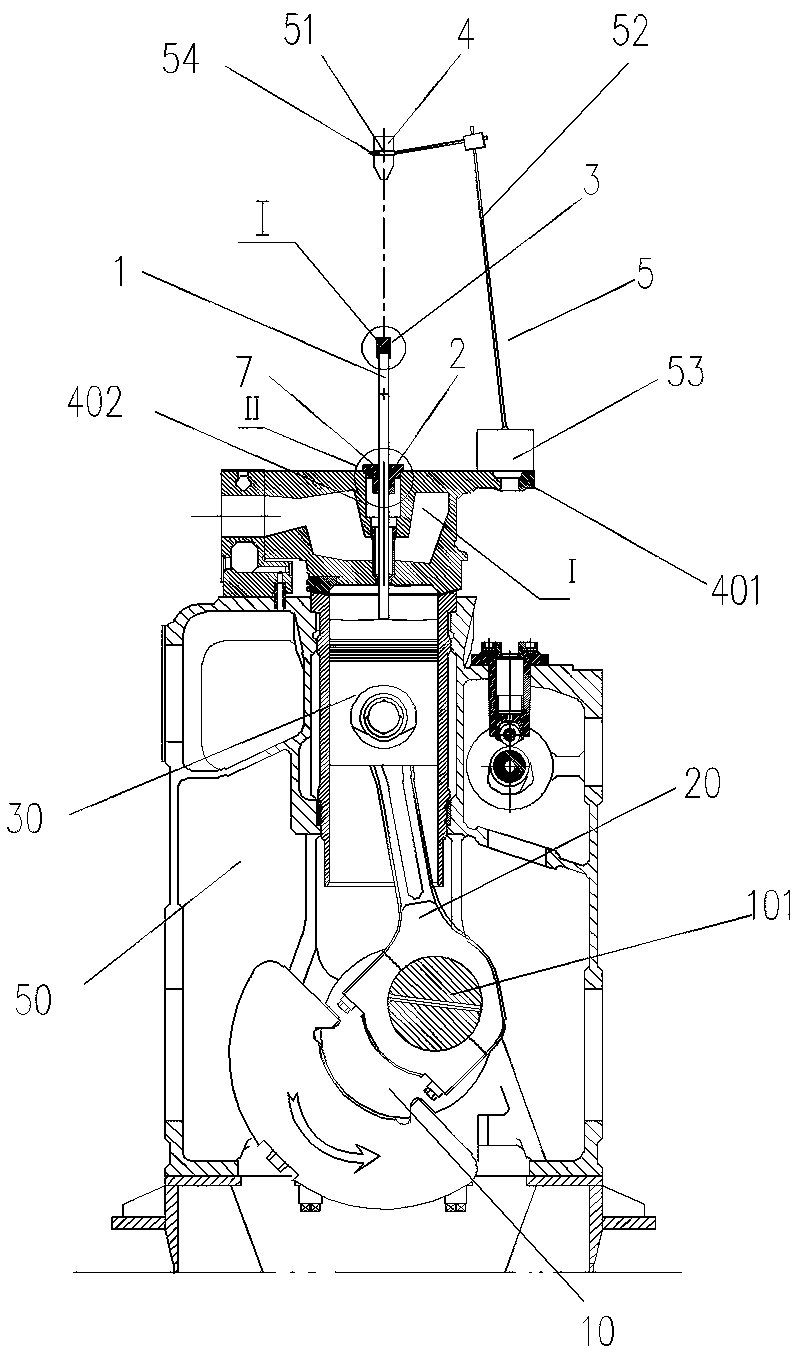

[0030] Such as figure 1 , figure 2 with Figure 4 As shown, the device of the present invention includes a guide rod 1, a positioning guide cylinder 2, a permanent magnet assembly 3, a Hall sensor 4, a sensor bracket 5 and a signal processor 6,

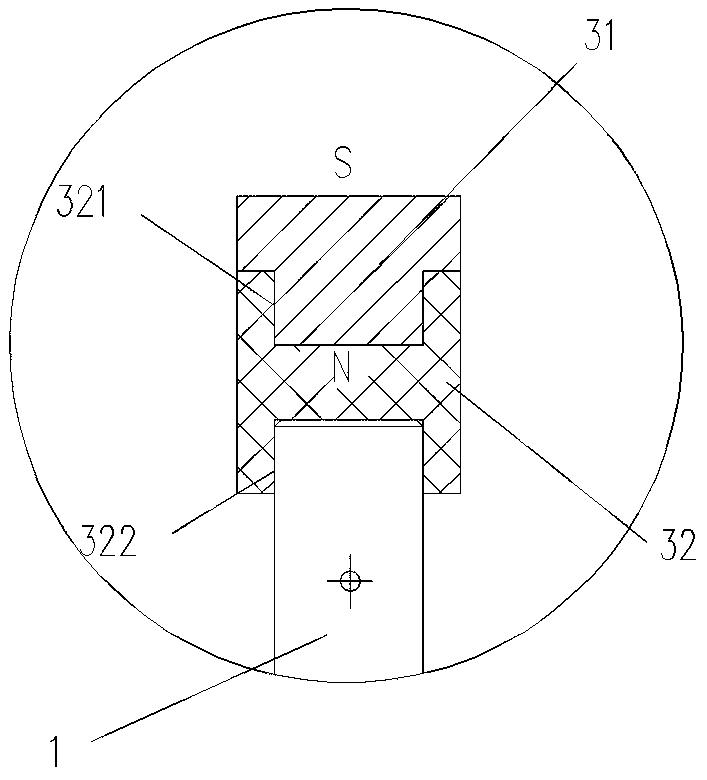

[0031] The positioning guide cylinder 2 is positioned in the fuel injector installation hole 402 of the cylinder head 401, the middle part of the guide rod 1 is in clearance fit with the positioning guide cylinder 2, the bottom of the guide rod 1 is against the top surface of the piston 30, and the permanent magnet assembly 3 is fixed on the guide rod 1. on the top of rod 1. The positioning guide cylinder 2 is a three-stage stepped shaft, and an O-ring 7 is embedded in the upper part of the stepped shaft. The upper part of the positioning guide cylinder 1 is positioned in the injector installation hole 402 through the O-rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com