A multifunctional flexible stress sensor

A stress sensor and multi-functional technology, applied in the field of stress sensors, can solve problems such as single function, inability to quantitatively analyze complex stress, etc., and achieve the effects of simple preparation process, simple structure and preparation method, and simple conversion output method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

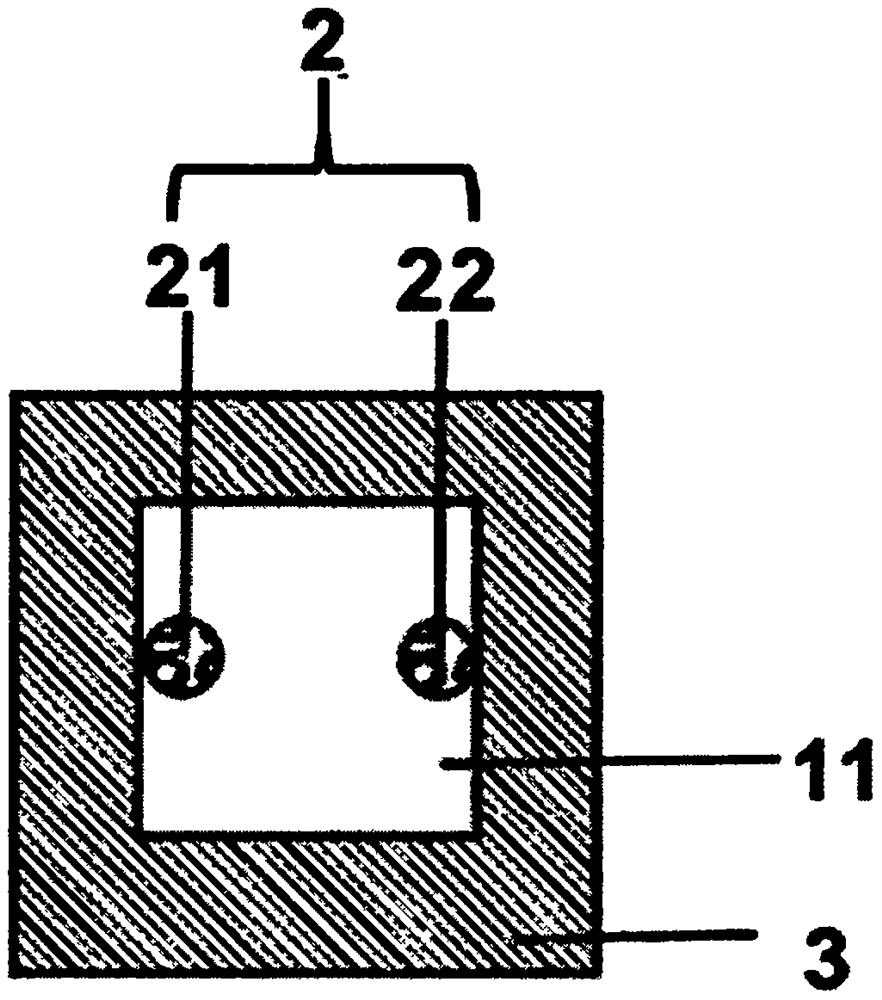

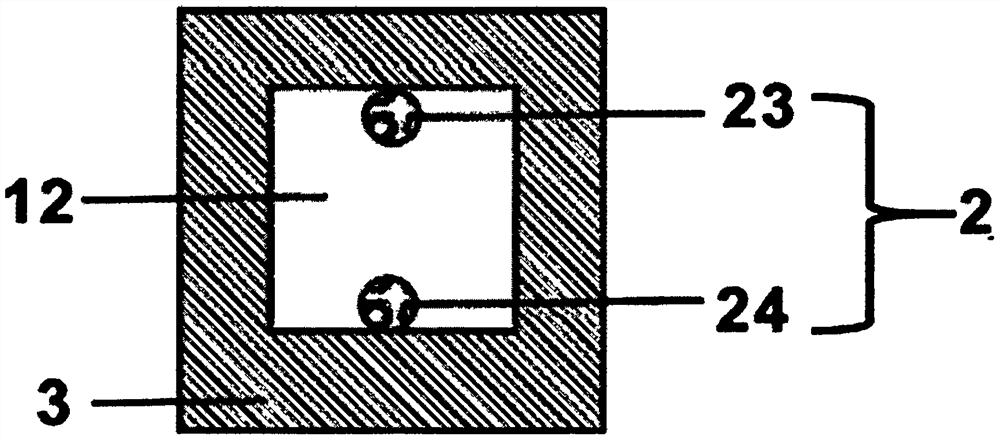

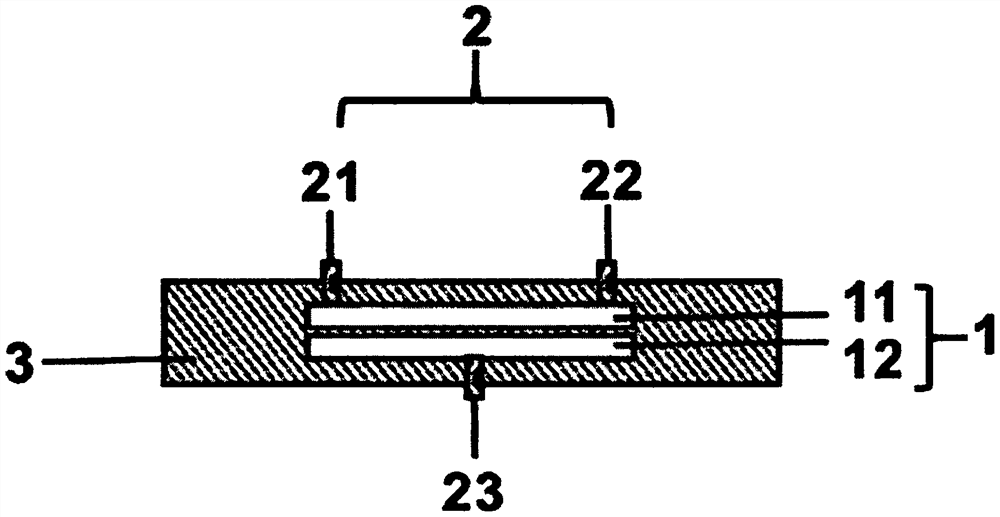

[0049] The elastic polymer 3 and the brittle polymer anisotropic conductive composite film 1 are squares of 30×30 mm and 20×20 mm respectively, and the former completely covers the latter, and their thicknesses are 2000 μm and 18 μm respectively. The degree of electrical anisotropy of the brittle polymer anisotropic conductive composite film 1 is 6.7, and the electrical conductivity in the main direction is 187 S / cm. The distance between the upper brittle polymer conductive composite film 11 and the upper surface of the elastic polymer 3 is 1000 μm. The resistance between the first conductive glue 21 and the second conductive glue 22 is denoted as R 1 , the resistance between the third conductive glue 23 and the fourth conductive glue 24 is denoted as R 2 . The pressure (P) and R on the sensor 1 and R 2 The relative change value (ΔR i , i=1, 2) The logarithm of the difference is linear, such as Figure 4 As shown, the regression equation is P=5.63lg(ΔR 1 -ΔR 2 )-8.40, ...

Embodiment 2

[0051] The elastic polymer 3 and the brittle polymer anisotropic conductive composite film 1 are circular with diameters of 15 mm and 10 mm respectively, and the former completely covers the latter, and their thicknesses are 1000 μm and 5 μm respectively. The electrical anisotropy value of the brittle polymer anisotropic conductive composite film 1 is 5, and the electrical conductivity in the main direction is 1000 S / cm. The distance between the upper brittle polymer anisotropic conductive composite film 11 and the upper surface of the elastic polymer 3 is 800 μm. The resistance between the first conductive glue 21 and the second conductive glue 22 is denoted as R 1 , the resistance between the third conductive glue 23 and the fourth conductive glue 24 is denoted as R 2 . Bending the sensor, the bending angle (θ) is the same as R 1 and R 2 The logarithm of the ratio of the relative change value is linear, such as Figure 5 As shown, the regression equation is θ=-16.4lg(ΔR...

Embodiment 3

[0053] The elastic polymer 3 and the brittle polymer anisotropic conductive composite film 1 are irregular in shape and a regular triangle with a side length of 10 mm, and the former completely covers the latter, and their thicknesses are 1500 μm and 10 μm, respectively. The electrical anisotropy value of the brittle polymer anisotropic conductive composite film 1 is 3, and the electrical conductivity in the main direction is 2000 S / cm. The distance between the upper brittle polymer anisotropic conductive composite film 11 and the upper surface of the elastic polymer (3) is 500 μm. The resistance between the first conductive glue 21 and the second conductive glue 22 is denoted as R 1 , the resistance between the third conductive glue 23 and the fourth conductive glue 24 is denoted as R 2 . Pressure on the sensor (P) and R 1 and R 2 The logarithm of the difference between the relative change values is linear, such as Image 6 As shown, the regression equation is P=-17.65...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com