Disc-shaft connection rotor system thermal analysis test bench and thermal deformation measurement method

A technology of thermal deformation and test bench, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc. It can solve the problems that it is difficult to accurately control the thermal characteristics and the thermal deformation of the spindle system is difficult to achieve accuracy, etc. , to achieve the effect of comprehensive and accurate control of content and results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and technical solutions.

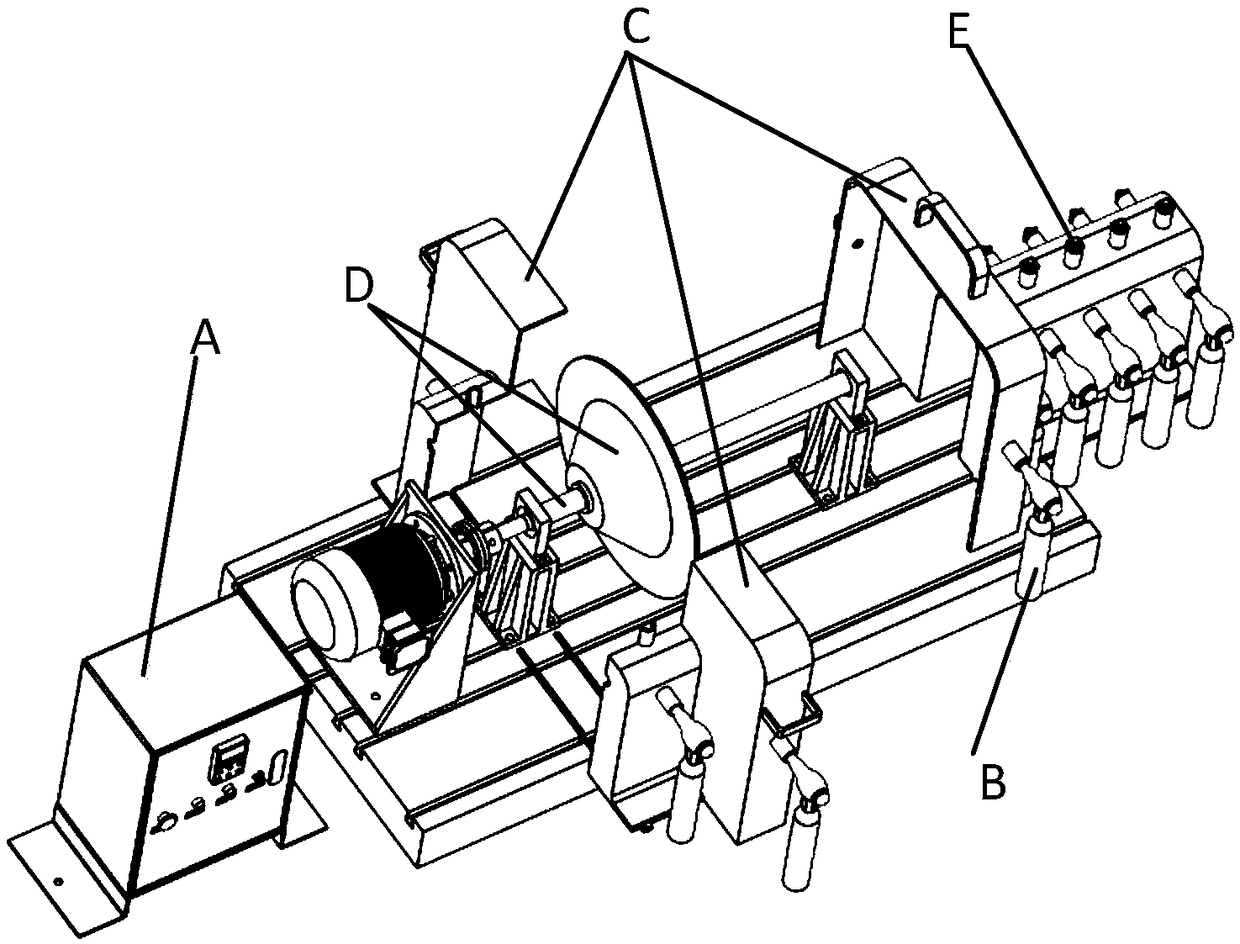

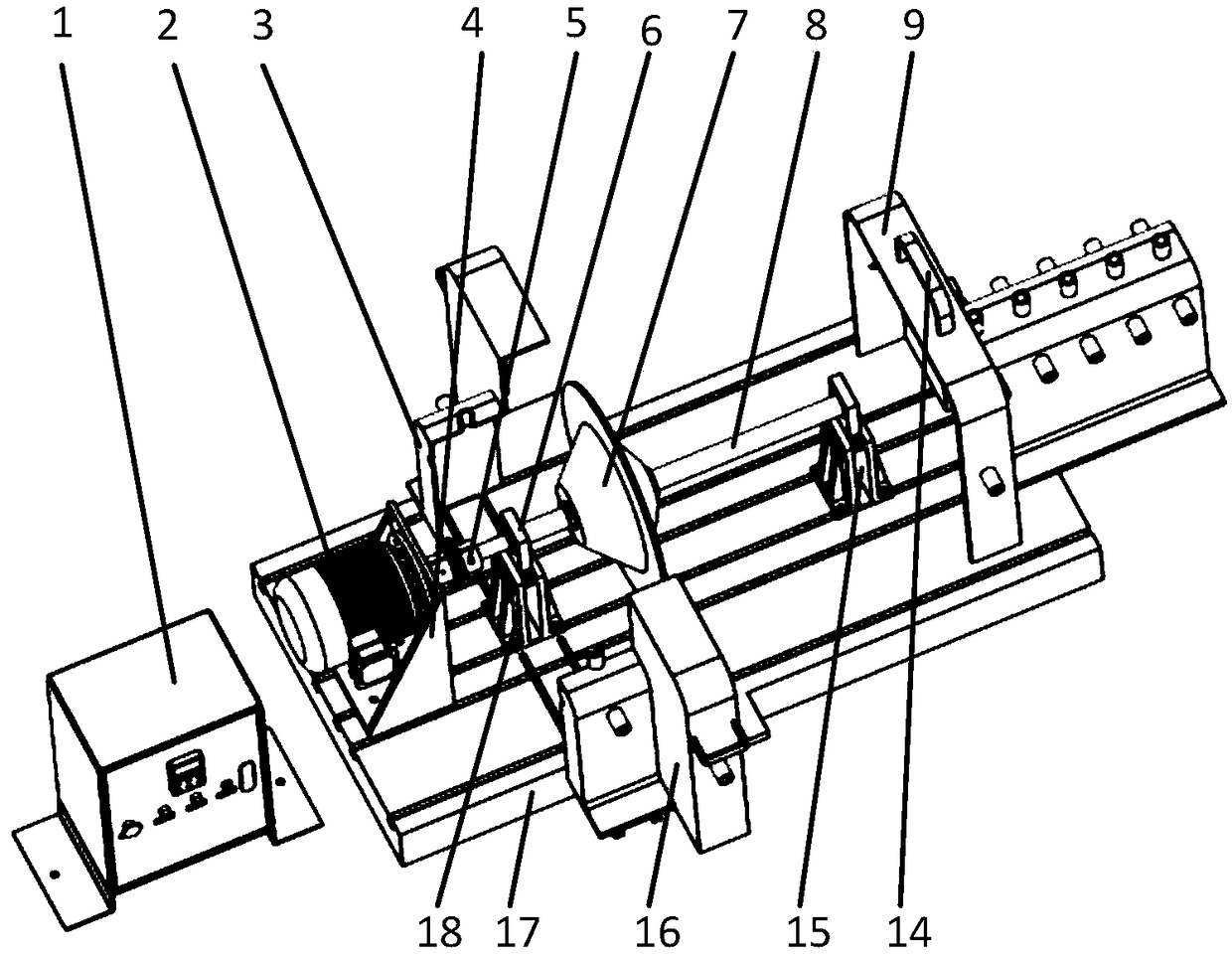

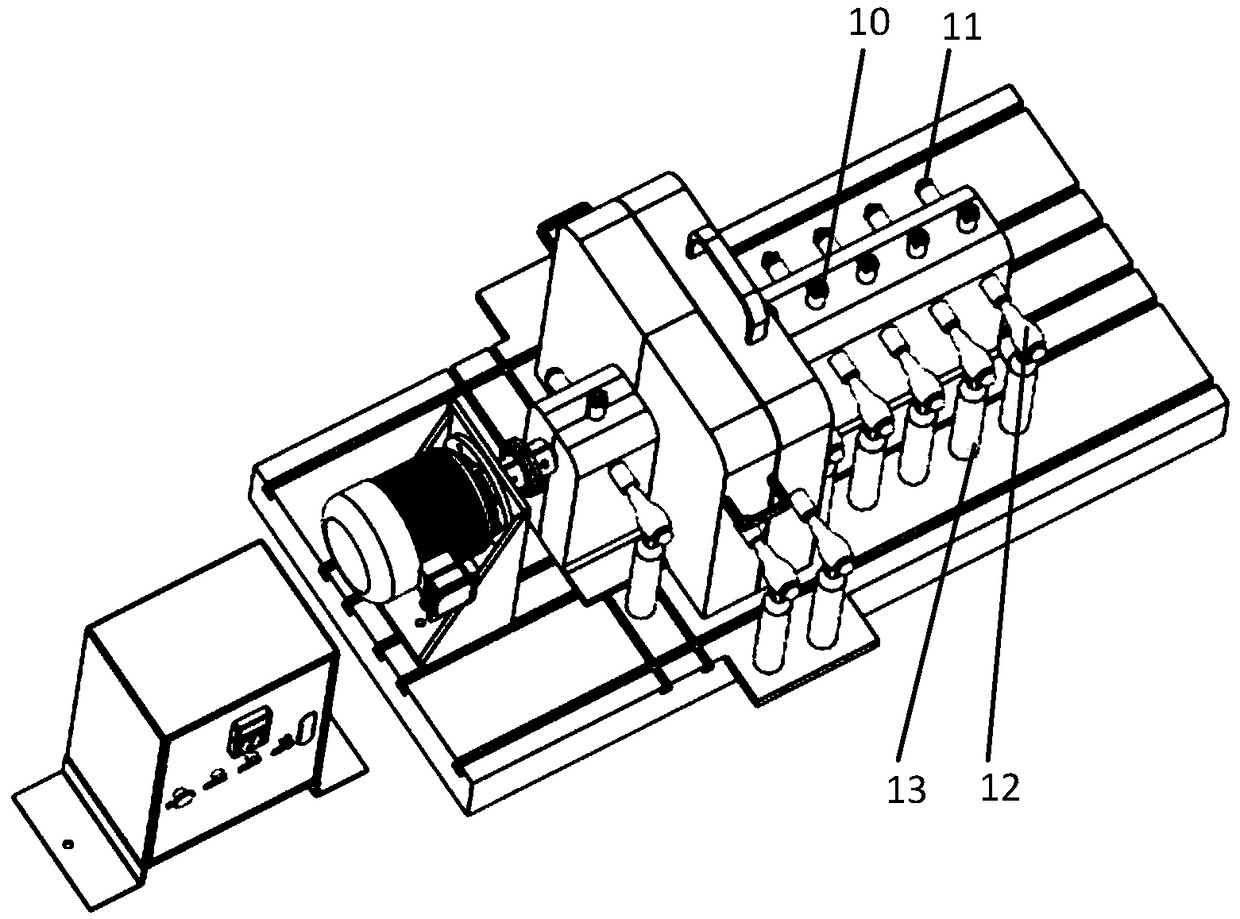

[0040] Such as figure 1 , 2 As shown, a thermal analysis test bench for a disc-shaft connection rotor system is mainly composed of an electric drive and control system A, an ignition system B, a heat insulation system C, a nonlinear support-rotor system D, a test sensor system E and a base 17 ;

[0041] The base 17 is equipped with a plurality of anchor bolts for fixing the motor support 4, the bearing support a15 and the bearing support b18, and serves as a slideway for the heat shield.

[0042] Such as Figure 4 As shown, the nonlinear support-rotor system D includes a disk structure 7 and a rotating shaft 8, and the two ends of the rotating shaft 8 fix the rotor on the bearing seat a15 and the bearing seat b18 through two bearings and the bearing seat 6 ; Disc shaft connection structure such as Figure 5(a) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com