Laser radar emitting system based on MEMS galvanometer

A laser radar and transmitting system technology, applied in radio wave measurement systems, instruments, etc., can solve the problems affecting the popularity of laser radar, high precision requirements for components, and high module manufacturing costs, to improve accuracy and to achieve consistency and resolution. The effect of improving efficiency and avoiding cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

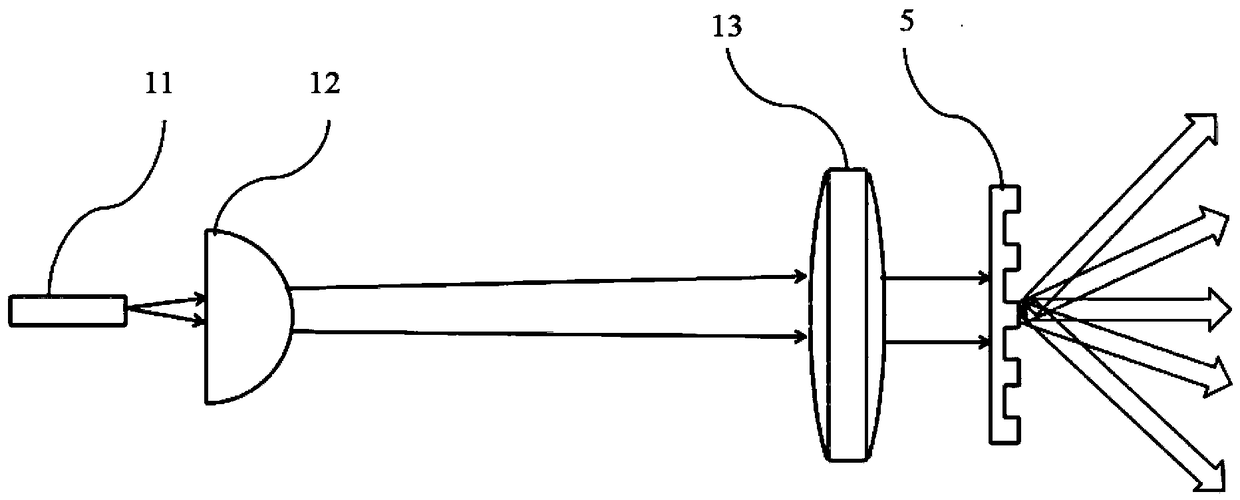

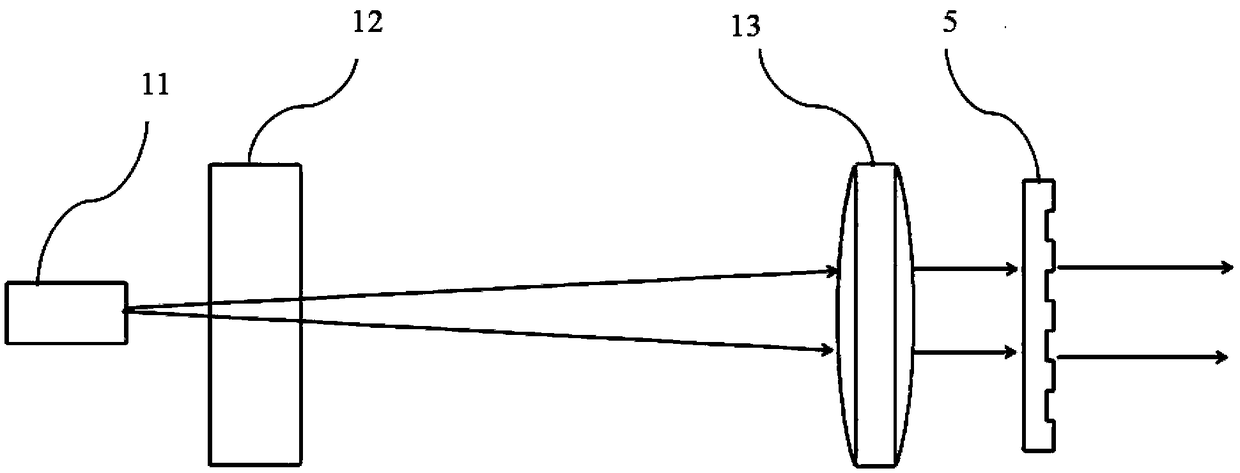

[0027] The lidar transmitting system in this embodiment includes a pulsed laser collimating transmitting module 1 and a diffractive beam splitting element 5; the pulsed laser collimating transmitting module 1 and the diffractive beam splitting element 5 are arranged correspondingly.

[0028] The pulsed laser collimation emission module 1 includes a laser 11, and the pulse laser collimation emission module 1 realizes the collimation processing of the light source of the laser 11 through a combination of optical systems, and the collimated laser after collimation is vertically incident into the On the diffractive beam splitting element 5, the diffractive beam splitting element 5 divides the vertically incident collimated laser evenly into several divergent beams, and the angle between the divergent beams can be adjusted by adjusting the diffractive beam splitting element 5 structure for precise control.

[0029] The laser radar transmitting system is also provided with a rotatin...

Embodiment 2

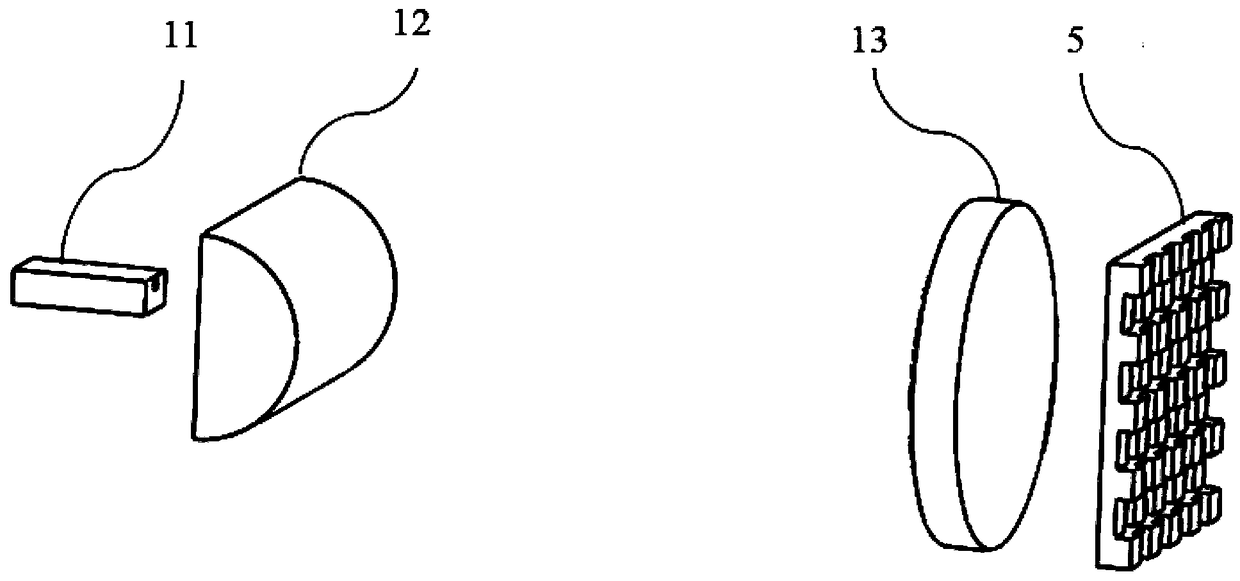

[0032] like figure 1 as shown, figure 1 It is a structural perspective view of Embodiment 2 of the lidar transmitting system; the pulsed laser collimating transmitting module 1 also includes a cylindrical lens 12 and an aspheric lens 13, and the cylindrical lens 12 and the aspheric lens 13 are arranged on the Between the laser 11 and the diffraction beam splitting element 5, the laser 11 is preferably a pulsed semiconductor laser; the diffraction beam splitting element 5 is preferably a diffraction grating beam splitting element.

[0033] Specifically, the size of the light emitting surface of the semiconductor laser 11 in the direction of the fast axis and the direction of the slow axis is quite different. Generally, the divergence angle of the laser light emitted by the laser 11 in the direction of the fast axis is relatively large.

[0034] Therefore, the present invention first compresses the divergence angle of the laser light emitted by the laser 11 in the direction of ...

Embodiment 3

[0040] Embodiment 3 is further improved on the basis of Embodiment 1. The improvement is that the lidar transmitting system further includes a mirror 3 and a rotating motor 4 .

[0041] like Figure 4 , Figure 5 as shown, Figure 4 It is a three-dimensional structure diagram of the third embodiment of the lidar transmitting system; Figure 5 It is a structural top view of Embodiment 3 of the laser radar transmitting system; the mirror 3 is connected to the rotating motor 4, and the rotating motor 4 can drive the mirror 3 to rotate so as to adjust the distance between the laser and the mirror 3 The included angle changes the incident angle and reflection angle of the laser light incident on the reflector 3 .

[0042] The reflector 3 is arranged between the pulse laser collimation emission module 1 and the diffraction beam splitting element 5; the pulse laser collimation emission module 1, the diffraction beam splitting element 5, the reflection mirror 3 and the rotary motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com