Industrial automatic control system

An automatic control system, industrial technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as inability to detect, control voltage, and control electrical power, and achieve scientific and reasonable structure and use. Safe and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

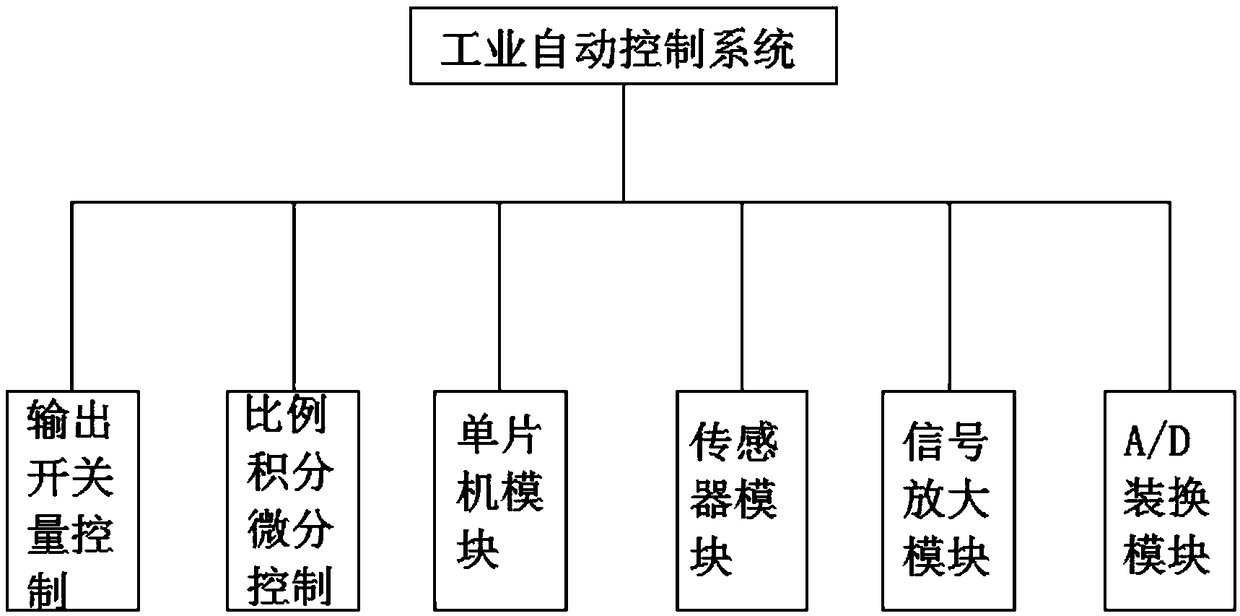

[0018] Example: such as figure 1 As shown, the present invention provides a technical solution, a kind of industrial automatic control system, including output switching value control, proportional integral differential control, single-chip microcomputer module, sensor module, signal amplification module and A / D conversion module, and the described output switching value is controlled by Compare the deviation between the given value and the controlled parameter to control the output state: switch or on-off, the output control quantity has only two states, so that the rate of change of the controlled parameter in both directions is the largest, so it is easy to generate a feedback loop oscillation.

[0019] Further, the proportional-integral-derivative control has a remarkable effect in overcoming the capacity hysteresis of the object, adding the differential action on the basis of the proportion to improve the stability, and adding the integral action to eliminate the residual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com