Method for prolonging circulation life of lithium ion battery with lithium nitride

A lithium-ion battery, cycle life technology, applied in batteries, battery electrodes, secondary batteries, etc., can solve problems such as poor cycle performance, and achieve the effects of small rate performance impact, uniform distribution, and improved cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

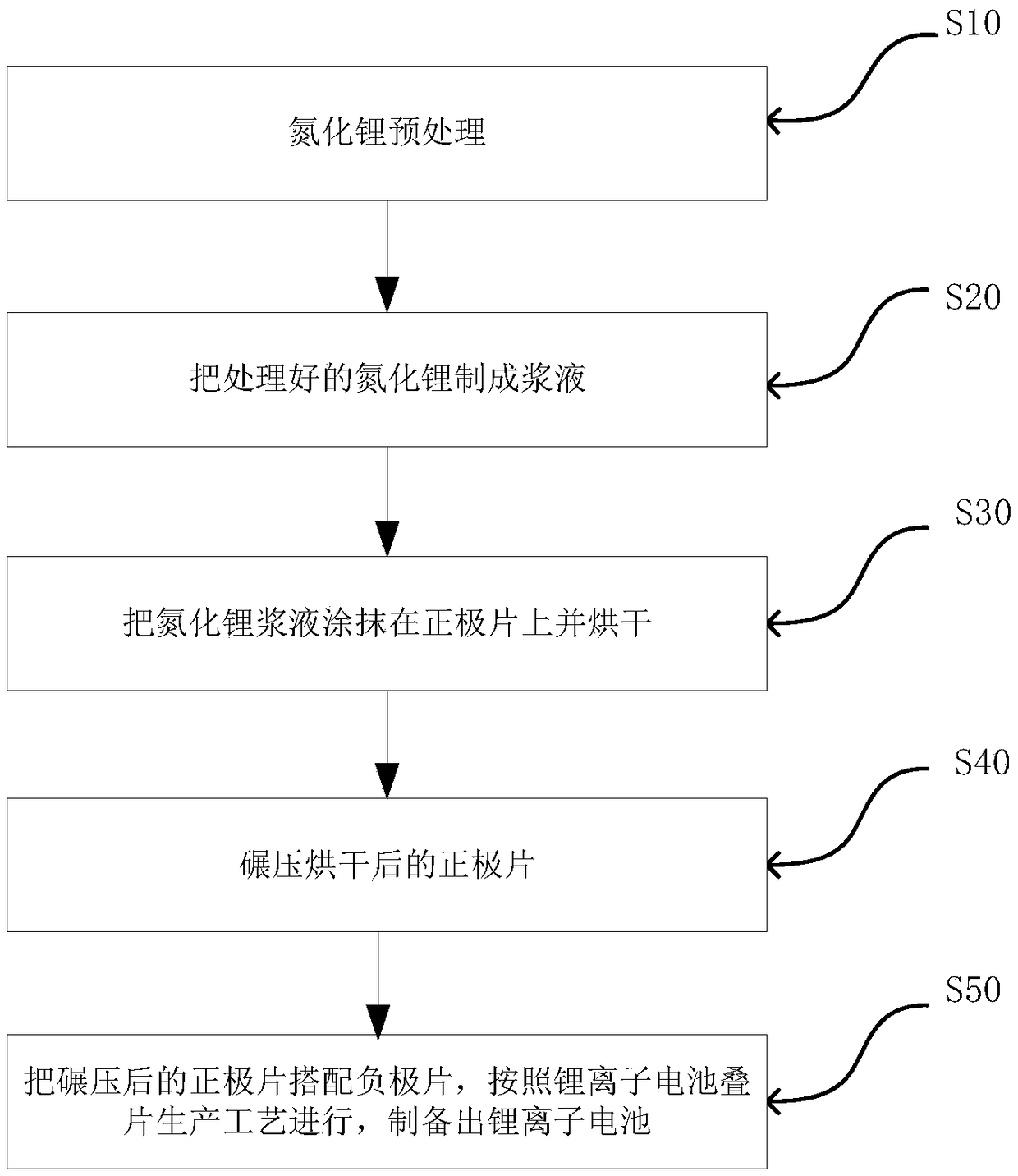

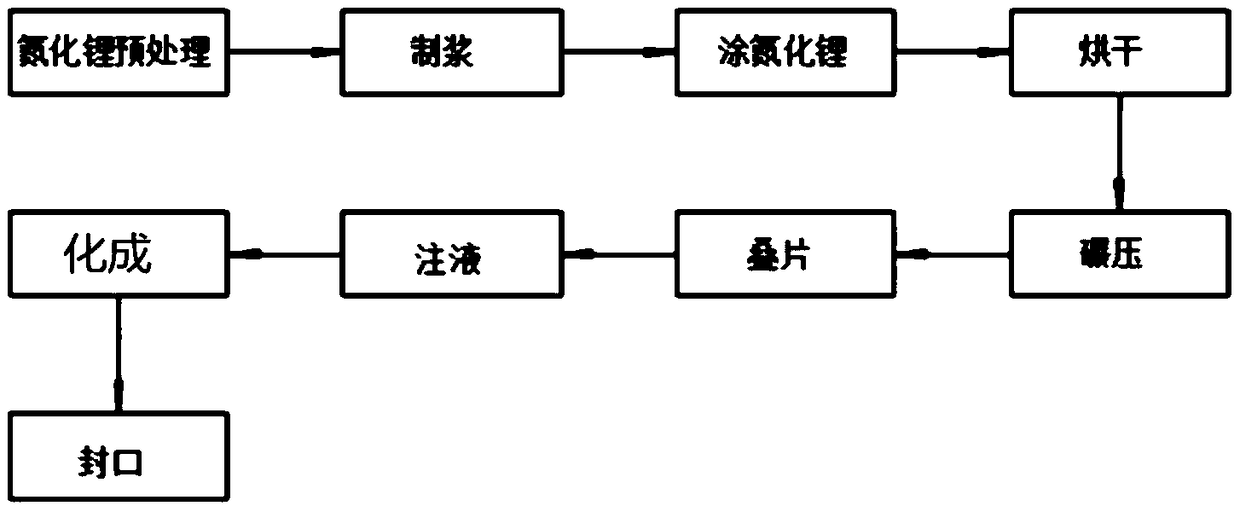

[0029] (1) Lithium nitride pretreatment: Weigh 1 kg of lithium nitride in the glove box, grind it fully with an agate mortar, seal it and store it for later use;

[0030] (2) Pulping: Weigh 600g of NMP and 6.7kg of PVDF respectively and put them into a stirring tank, stir in vacuum for 4 hours to make a glue, the dispersion rate is 800r / min, and the temperature is controlled at 20-50°C; the ground lithium nitride powder Add in a stirring tank, stir in vacuum for 8 hours, disperse at a rate of 1000r / min, add NMP to adjust the viscosity to 3000-6000mPa·s;

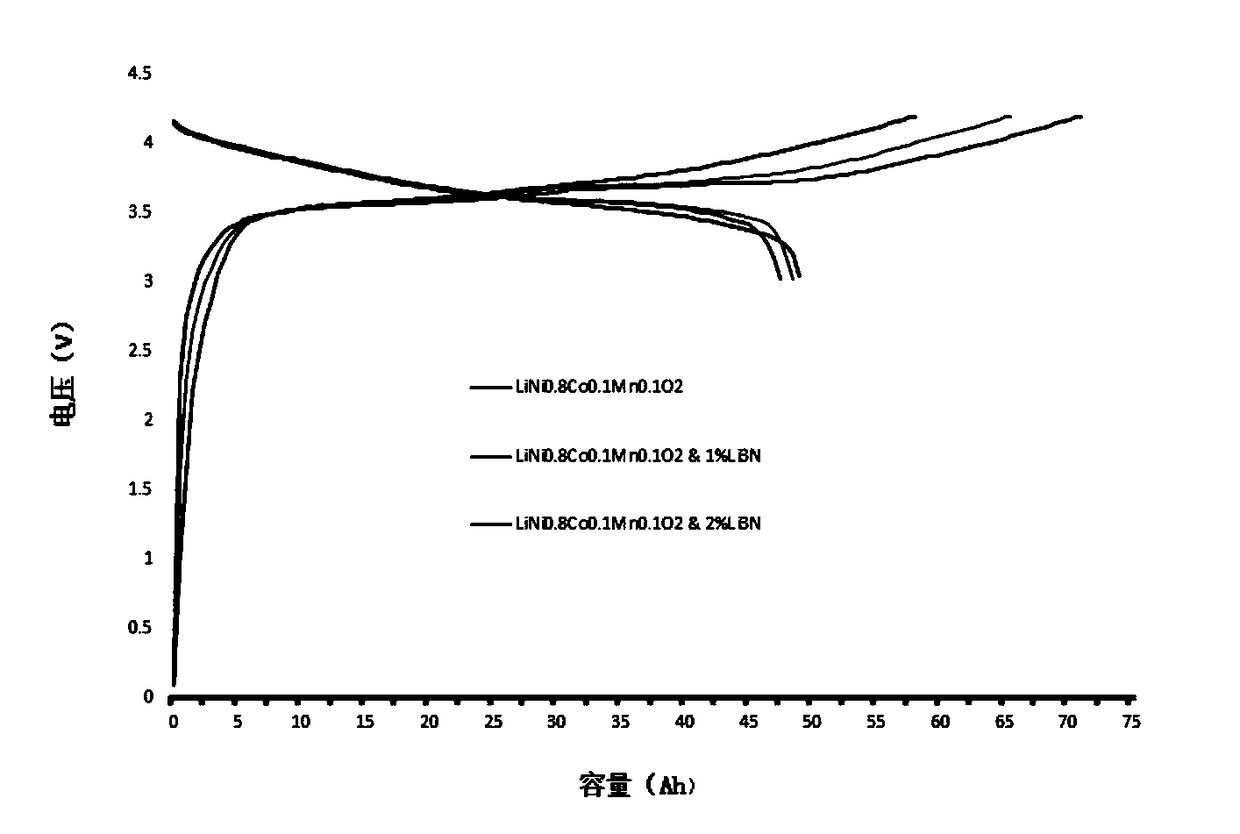

[0031] (3) Take the ternary positive electrode sheet (the main material is LiNi 0.8 co 0.1 mn 0.1 o 2 ) Use a coating machine to evenly coat the prepared lithium nitride slurry on the surface of the positive electrode sheet, and control the coating surface density to 0.4±0.1g / m 2 (1%), and dried;

[0032] (4) Use a rolling machine to roll the positive electrode sheet, and the thickness after rolling is controlled at 126±...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com