Surface treatment process for hydrophilic-group silica gel

A surface treatment, hydrophilic-based technology, applied in the field of hydrophilic-based silica gel surface treatment technology, can solve the problems of poor comfort, stickiness, sticking to hands, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

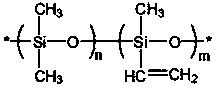

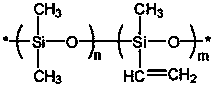

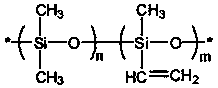

Image

Examples

Embodiment Construction

[0024] A hydrophilic-based silica gel surface treatment process, comprising the following steps,

[0025] (1) Place a plurality of silicone parts at intervals in the discharging jig, so that the sides of the plurality of silica gel parts can also be irradiated;

[0026] (2) Set the temperature, conveyor belt transmission rate and irradiation time in the control system of the hydrophilic base machine, and then start the hydrophilic base machine, the conveyor belt of the hydrophilic base machine will start to run, and the suction system of the hydrophilic base machine will The hot air in the tunnel furnace of the hydrophilic base machine is discharged, and the normal temperature air enters the tunnel furnace at the same time;

[0027] (3) After the hot air in the tunnel furnace is completely exhausted, the exhaust system stops working. At this time, the multiple hydrophilic-based lamps in the tunnel furnace are turned on from the cold state, and the illuminance and temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com