Silk-screen printing heat-conducting silicon grease and preparation method thereof

A technology of thermal conductive silicone grease and silk screen printing, which is applied in the field of silicone grease, can solve the problems of complex process and high cost of raw materials, and achieve the effect of simple process, good fluidity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

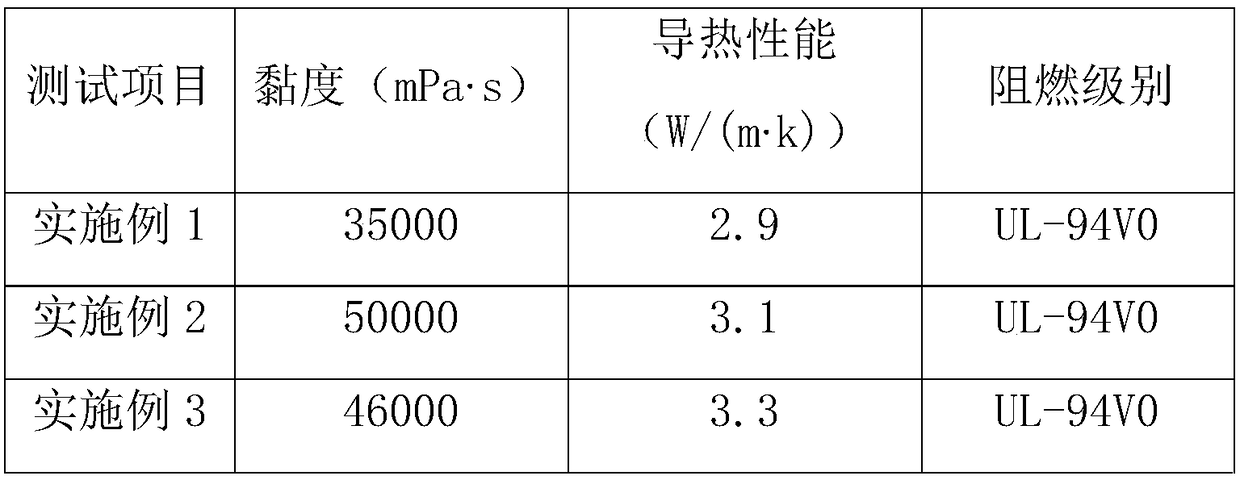

Examples

Embodiment 1

[0038] A kind of silk screen thermal conductive silicone grease, comprising the following raw materials in parts by weight,

[0039] 5 parts of polyether modified simethicone oil;

[0040] 100 parts of thermally conductive filler;

[0041] The thermally conductive filler is a mixture of silane coupling agent-modified spherical alumina powder and silane coupling agent-modified zinc oxide powder in a weight ratio of 3:1.

[0042]Further, the silane coupling agent modified spherical alumina powder and silane coupling agent modified zinc oxide powder are made by the following method: (a) adding spherical alumina powder and silane coupling agent to the In water and ethanol, prepare ethanol solution, stir and react at room temperature and normal pressure for 60 minutes, wherein the stirring speed is 40 rpm; (b) bake the reaction solution in step (a) at 80°C for 60 minutes to obtain silane Coupling agent modified spherical alumina powder; (c) adding zinc oxide powder and silane cou...

Embodiment 2

[0052] A kind of silk screen thermal conductive silicone grease, comprising the following raw materials in parts by weight,

[0053] 20 parts of polyether modified simethicone oil;

[0054] Thermally conductive filler 1000 parts;

[0055] The thermally conductive filler is a mixture of silane coupling agent-modified spherical alumina powder and silane coupling agent-modified zinc oxide powder in a weight ratio of 6:1.

[0056] Further, the silane coupling agent modified spherical alumina powder and silane coupling agent modified zinc oxide powder are made by the following method: (a) adding spherical alumina powder and silane coupling agent to the In water and ethanol, prepare ethanol solution, stir and react at room temperature and normal pressure for 60 minutes, wherein the stirring speed is 60 rpm; (b) bake the reaction solution in step (a) at 120°C for 30 minutes to obtain silane Coupling agent modified spherical alumina powder; (c) adding zinc oxide powder and silane co...

Embodiment 3

[0067] A kind of silk screen thermal conductive silicone grease, comprising the following raw materials in parts by weight,

[0068] 20 parts of polyether modified simethicone oil;

[0069] 500 parts of thermally conductive filler;

[0070] The thermally conductive filler is a mixture of silane coupling agent-modified spherical alumina powder and silane coupling agent-modified zinc oxide powder in a weight ratio of 8:1.

[0071] Further, the silane coupling agent modified spherical alumina powder and silane coupling agent modified zinc oxide powder are made by the following method: (a) adding spherical alumina powder and silane coupling agent to the In water and ethanol, prepare ethanol solution, stir and react at room temperature and normal pressure for 60min, wherein the stirring speed is 60rpm; (b) bake the reaction solution in step (a) at 100°C for 40min to obtain silane Coupling agent modified spherical alumina powder; (c) adding zinc oxide powder and silane coupling ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com