Heating treatment process for eliminating ribbon structure of R26 high temperature alloy bolt

A technology of superalloy and banded structure, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problem of weakening the effect of solid solution strengthening and dispersion strengthening of bolts, reducing bolt performance and service life, and destroying the internal uniformity and continuity of materials, etc. problems, to achieve the effect of optimizing the heat treatment process, improving the mechanical properties, and increasing the yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

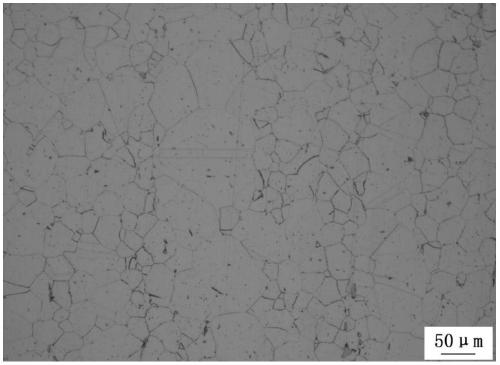

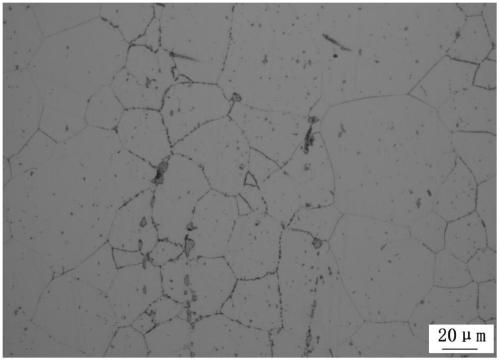

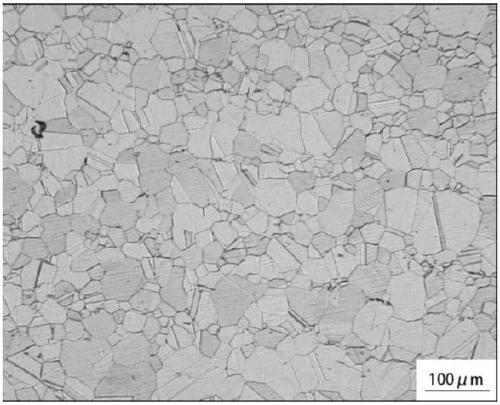

Image

Examples

Embodiment 1

[0026] A heat treatment process for eliminating the ribbon structure of R26 superalloy bolts proposed by the present invention includes the following steps:

[0027] S1. Solution treatment: Select R26 superalloy bolts with banded structure after the main valve of the 600MW supercritical unit is in service, cut axially from the R26 superalloy bolts as samples, and put the samples into KSL-1100X box-type resistors Heating in a furnace with a heating rate of 5 °C / min, heating up with the furnace, heating to 1030 °C, holding for 15 minutes, then taking out the sample and placing it in engine oil to cool to room temperature;

[0028] S2. Intermediate treatment: put the solution-treated sample into the KSL-1100X box-type resistance furnace, the heating rate is 5°C / min, the temperature is raised to 815°C, and the temperature is kept for 6h;

[0029] S3. Aging treatment: The sample after intermediate treatment is furnace cooled to 730°C at a cooling rate of 10°C / min, kept for 4 hours,...

Embodiment 2

[0031] A heat treatment process for eliminating the ribbon structure of R26 superalloy bolts proposed by the present invention includes the following steps:

[0032] S1. Solution treatment: heat the sample to 980°C at a heating rate of 1°C / min, keep the temperature for 20min, and cool the oil to room temperature;

[0033] S2. Intermediate treatment: heat the solution-treated sample to 830°C at a heating rate of 4°C / min, and keep the temperature for 5h;

[0034] S3. Aging treatment: Cool the sample after intermediate treatment to 710°C at a cooling rate of 5°C / min, keep the temperature for 5h, and air-cool to room temperature.

Embodiment 3

[0036] A heat treatment process for eliminating the ribbon structure of R26 superalloy bolts proposed by the present invention includes the following steps:

[0037] S1. Solution treatment: The R26 superalloy bolt with banded structure is heated to 1050°C at a heating rate of 4°C / min, kept for 10 minutes, and the oil is cooled to room temperature;

[0038] S2. Intermediate treatment: heat the solution-treated sample to 800°C at a heating rate of 1°C / min, and keep the temperature for 7h;

[0039] S3. Aging treatment: The sample after intermediate treatment is furnace cooled to 750°C at a cooling rate of 8°C / min, kept for 3 hours, and air-cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com