Cobalt-based bulk amorphous alloy and preparation method thereof

An amorphous alloy, cobalt-based technology, applied in the field of cobalt-based bulk amorphous alloy and its preparation, can solve the problem of increasing raw material and preparation costs, hindering the large-scale application and development of Co-based bulk amorphous alloy, and unfavorable research and development. Develop ultra-high-strength metal materials and other issues to achieve high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present application also provides a method for preparing the cobalt-based bulk amorphous alloy, comprising the following steps:

[0052] A) batching is carried out according to the atomic percentage of each element of the cobalt-based bulk amorphous alloy shown in formula (I);

[0053] B) melting the raw materials obtained in step A) to obtain a master alloy ingot;

[0054] C) performing water-cooled copper mold suction casting on the master alloy ingot, rapid solidification and cooling to obtain a cobalt-based bulk amorphous alloy;

[0055] co a W b B c (I);

[0056] Wherein, a, b and c are the atomic percentages of corresponding elements;

[0057] a=54-70; b=15-30; c=12-19; a+b+c=100.

[0058] In the process of preparing the cobalt-based bulk amorphous alloy, batching is carried out first, and the batching process is carried out in a manner well known to those skilled in the art, and there is no special limitation here. In a specific embodiment, the mass...

Embodiment 1 3

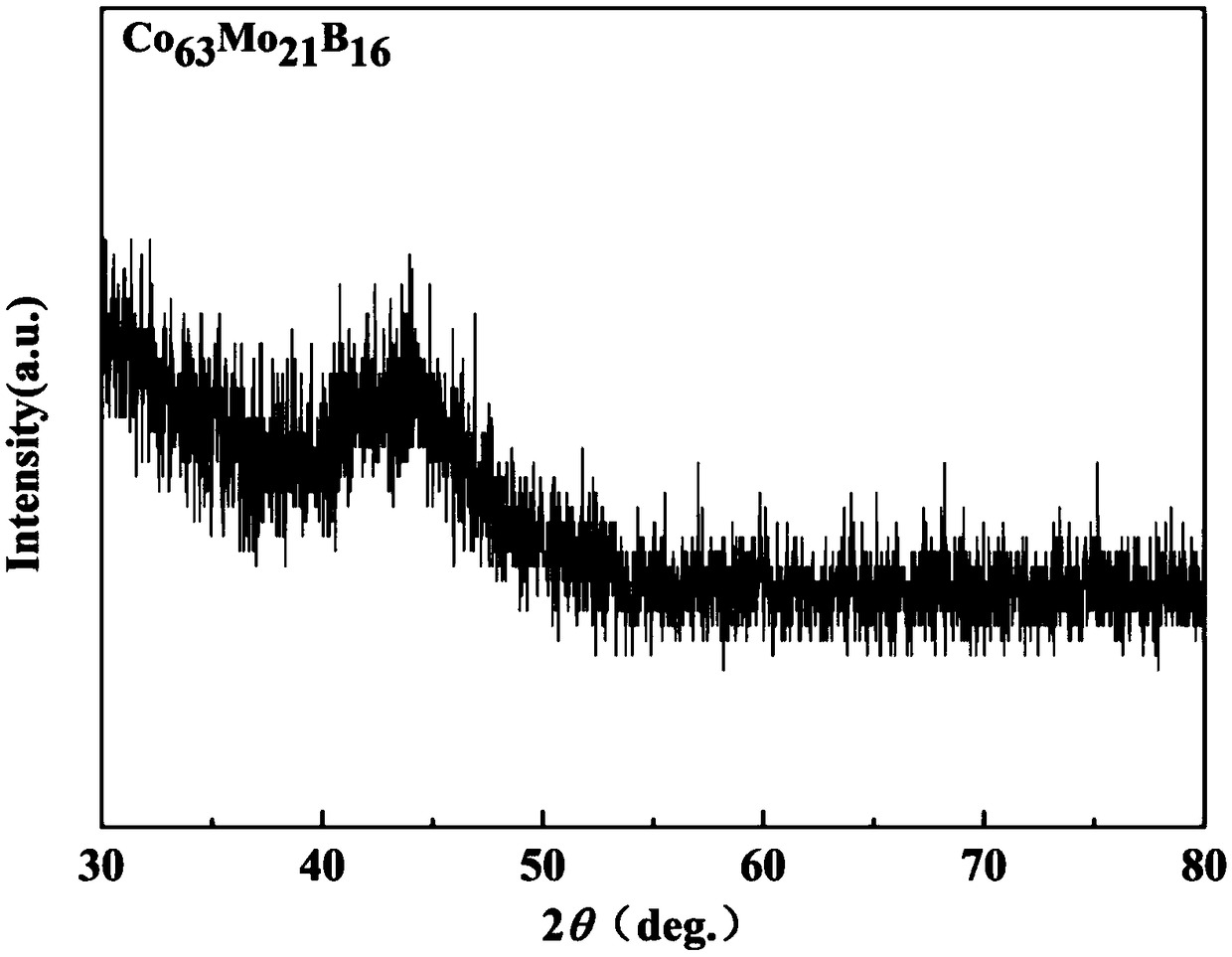

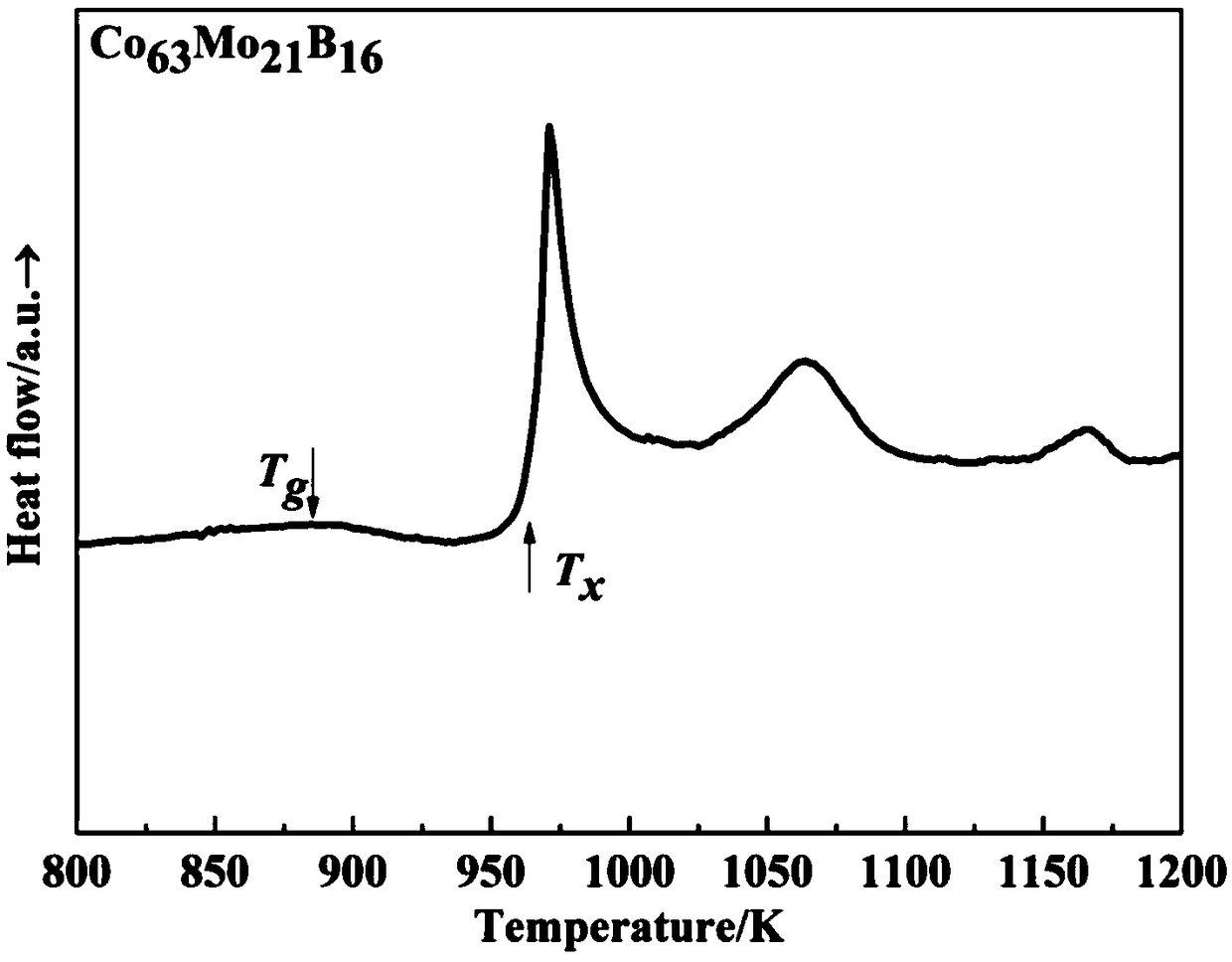

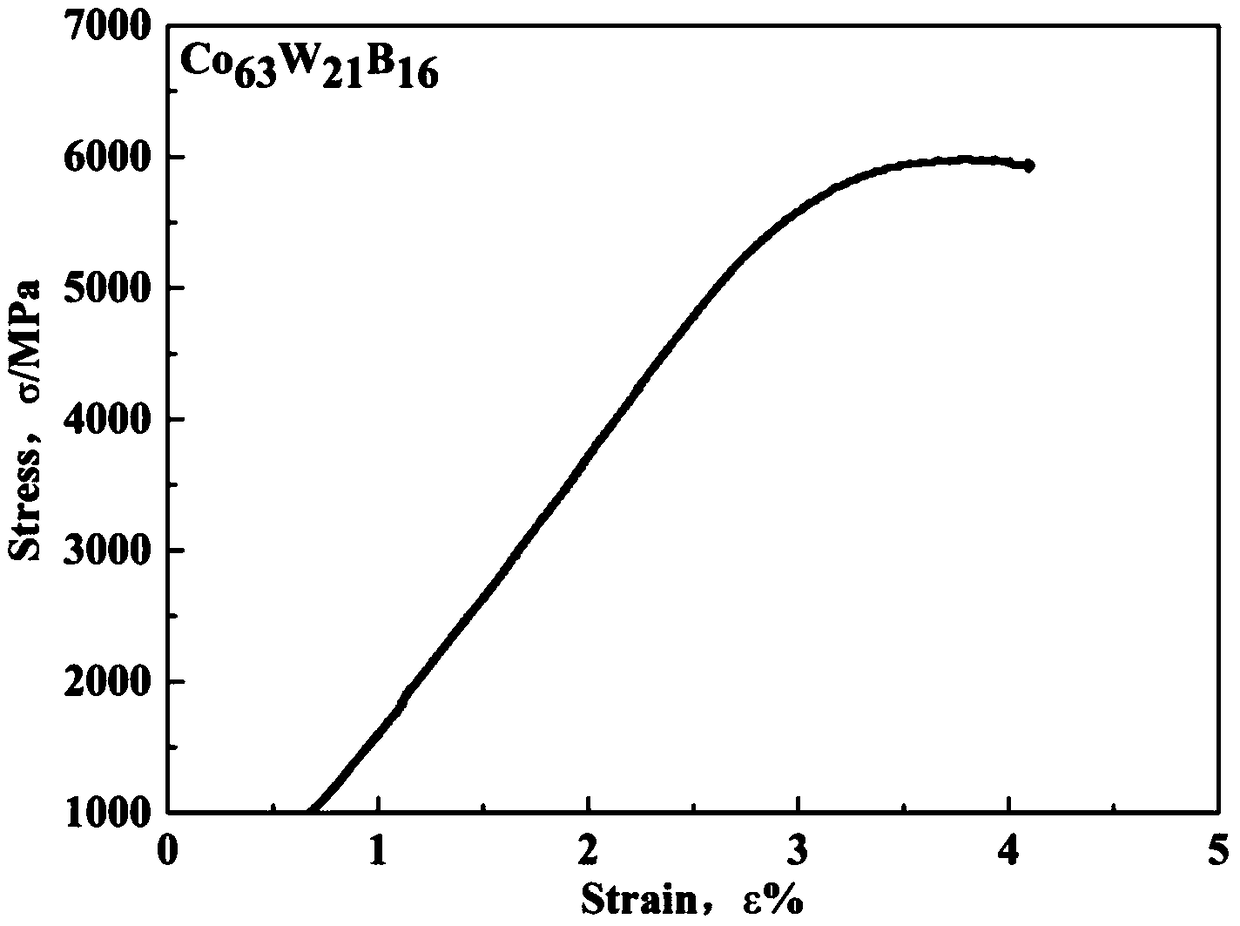

[0064] Example 1 Ternary Co 63 W 21 B 16 Preparation of bulk amorphous alloys

[0065] Step 1: Ingredients

[0066] According to Co a W b B c The target composition of the ternary bulk amorphous alloy takes three kinds of raw materials Co, W and B, and the metal raw materials need to polish the surface oxide skin, and the mass percentage purity of each raw material needs to be higher than 99.9%; the Co a W b B c Among them, Co is metal cobalt Co, W is metal tungsten W, B is elemental boron B, a, b, and c are atomic percentages, a=63, b=21, c=16, and a+b+c=100;

[0067] Step 2: Melting into alloy ingots and preparing Co in a vacuum electric arc furnace 63 W 21 B 16 bulk amorphous alloy

[0068] Put the prepared raw materials into the vacuum electric arc furnace, and then evacuate to 4×10 -3 Below Pa, fill in 0.05MPa argon again, and continue vacuuming to 4×10 -3 Below Pa, refill with 0.2MPa argon; under the protection of an argon atmosphere with a mass percentage ...

Embodiment 2

[0074] Example 2Co 59 W 26 B 15 Preparation of bulk amorphous alloys

[0075] Step 1: Ingredients

[0076] According to Co a W b B c The target composition of the ternary bulk amorphous alloy takes three kinds of raw materials Co, W and B, and the metal raw materials need to polish the surface oxide skin, and the mass percentage purity of each raw material needs to be higher than 99.9%; the Co a W b B c Among them, Co is metal cobalt Co, W is metal tungsten W, B is elemental boron B, a, b, and c are atomic percentages, where a=59, b=26, c=15, and a+b+c= 100;

[0077] Step 2: Melting alloy ingots and Co in a vacuum electric arc furnace 59 W 26 B 15 Bulk amorphous alloy Put the prepared raw materials into the vacuum electric arc furnace, and then vacuumize to 4×10 -3 Below Pa, fill in 0.05MPa argon again, and continue vacuuming to 4×10 - 3 Below Pa, refill with 0.2MPa argon; under the protection of an argon atmosphere with a mass percentage of high purity of 99.99...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com