Method for rapidly detecting silicon crystal defects on semiconductor wafer substrate

A detection method and technology of silicon crystal, applied in semiconductor/solid state device testing/measurement, electrical components, circuits, etc., can solve problems such as influence, difficulty in obtaining repeatable scribing results, achieve accurate repeatability, and avoid artificial defect artifacts , the effect of good etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

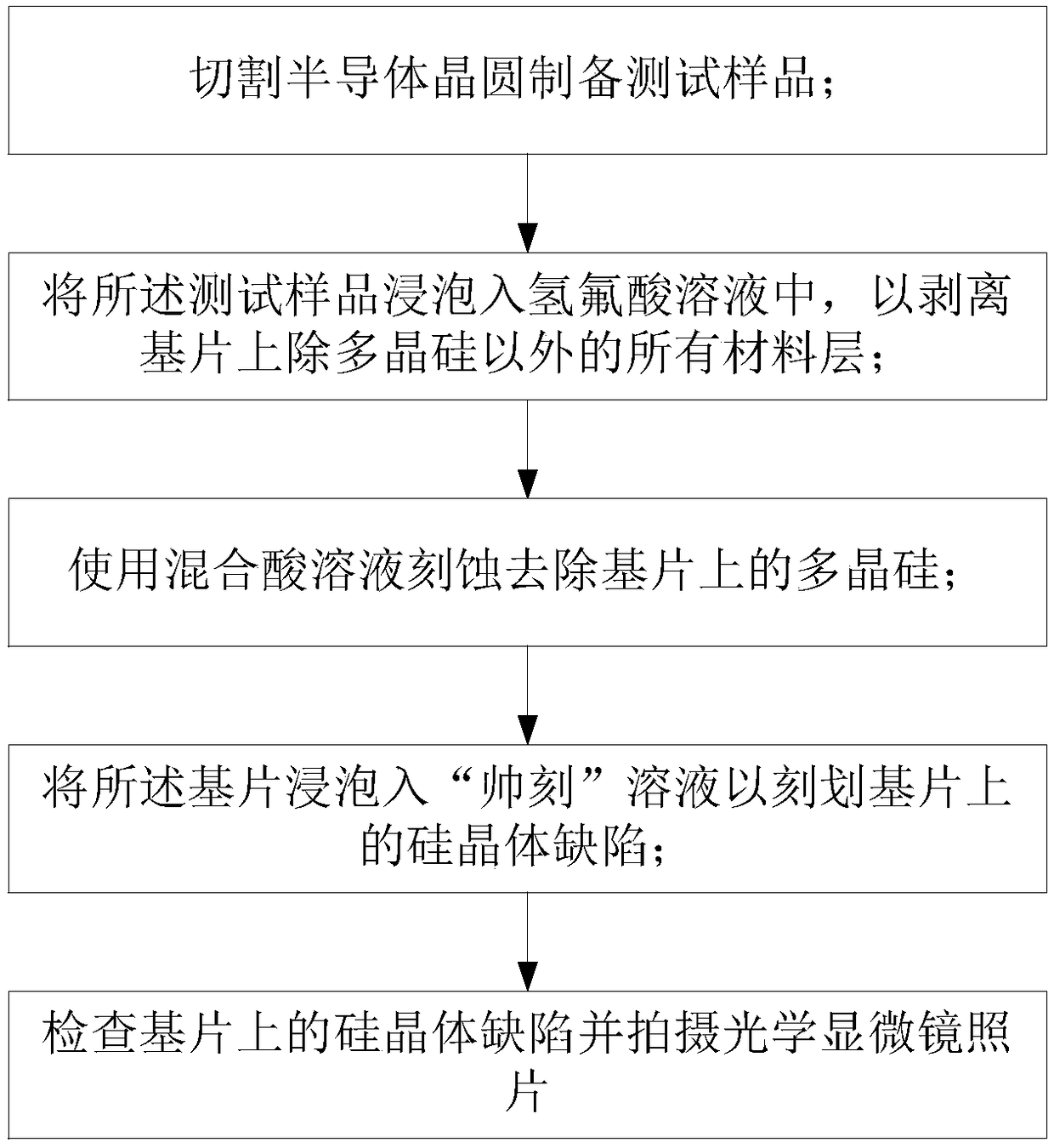

[0018] Such as figure 1 As shown, the present invention provides a kind of rapid detection method of silicon crystal defect on semiconductor wafer substrate, comprising:

[0019] Cut the semiconductor wafer to prepare the required test samples. Generally, the length and width of the test samples are selected as 2x2 cm in size;

[0020] The test sample was immersed in a hydrofluoric acid solution to peel off all material layers in the test sample except the substrate and the polysilicon layer. Wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com