Degradable self-supported thin-film transistor device and production method thereof

A self-supporting thin film and transistor technology, which is applied in semiconductor/solid-state device manufacturing, transistors, semiconductor devices, etc., can solve environmental pollution and other problems, and achieve the effects of simple preparation process, good channel regulation performance, and simplified material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

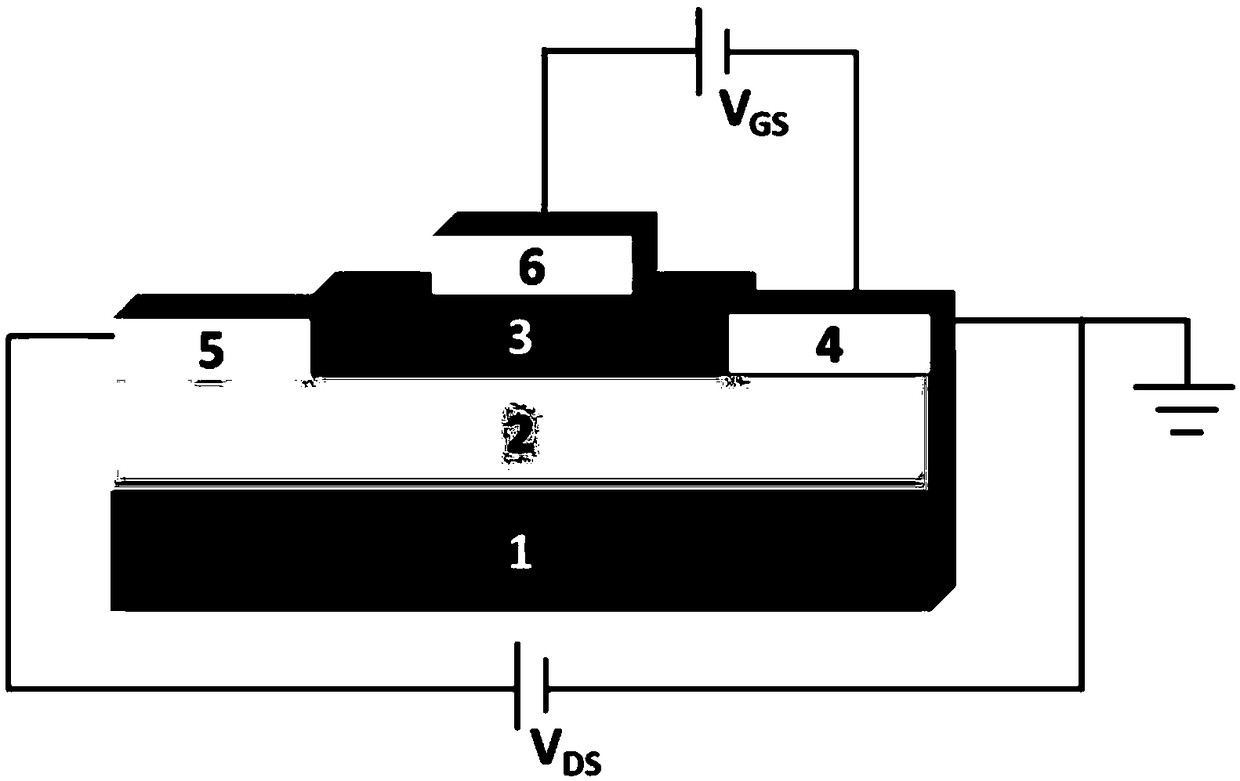

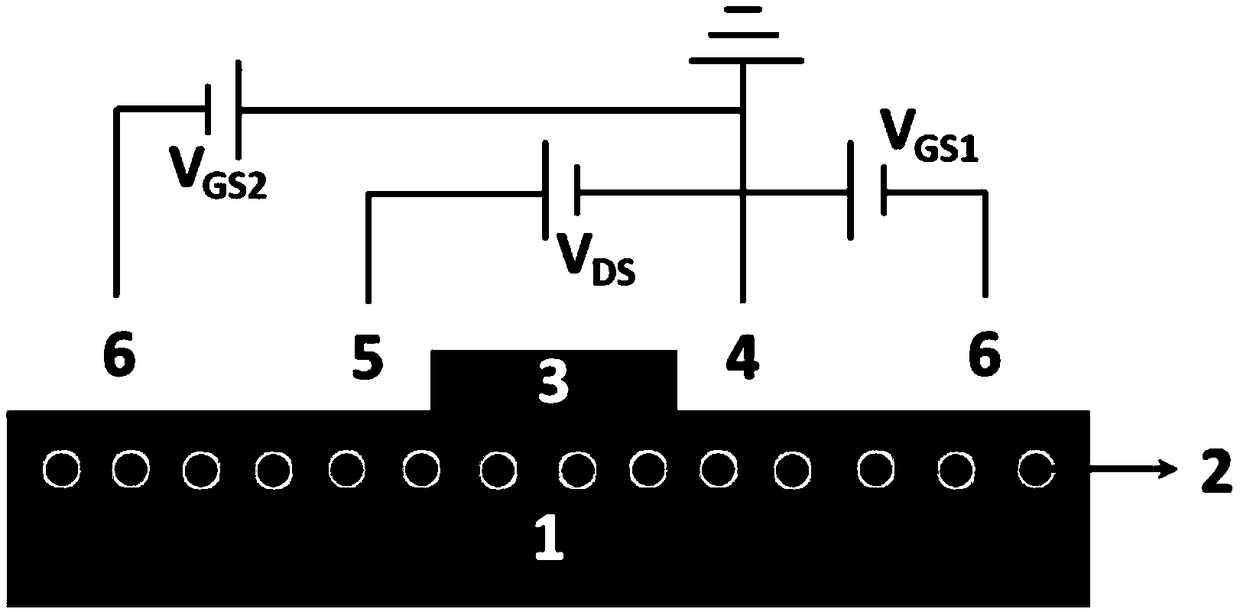

[0025] Such as figure 2 As shown, the present invention works and implements like this, a degradable self-supporting thin film transistor device mainly includes a self-supporting dielectric layer 1, a semiconductor active layer 3, a source electrode 4, a drain electrode 5 and a gate electrode 6 ; It is characterized in that: the degradable self-supporting thin film transistor device adopts the natural high molecular polymer film with ion-conducting properties of movable ions 2 in the dielectric layer as the self-supporting dielectric layer 1, on the self-supporting dielectric layer 1 Then deposit the semiconductor active layer 3 and the coplanar source electrode 4 , drain electrode 5 and gate electrode 6 in sequence, wherein the semiconductor active layer 3 is arranged between the source electrode 4 and the drain electrode 5 .

[0026] A method for preparing a degradable self-supporting thin film transistor device according to the present invention is characterized in that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com