Turbo compressor fuel tank flue gas recovery device

A technology of turbo compressor and flue gas recovery, which is applied in the direction of combination device, transportation and packaging, dispersed particle filtration, etc., can solve the problems of easy oil leakage, poor oil and gas separation effect, etc. good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

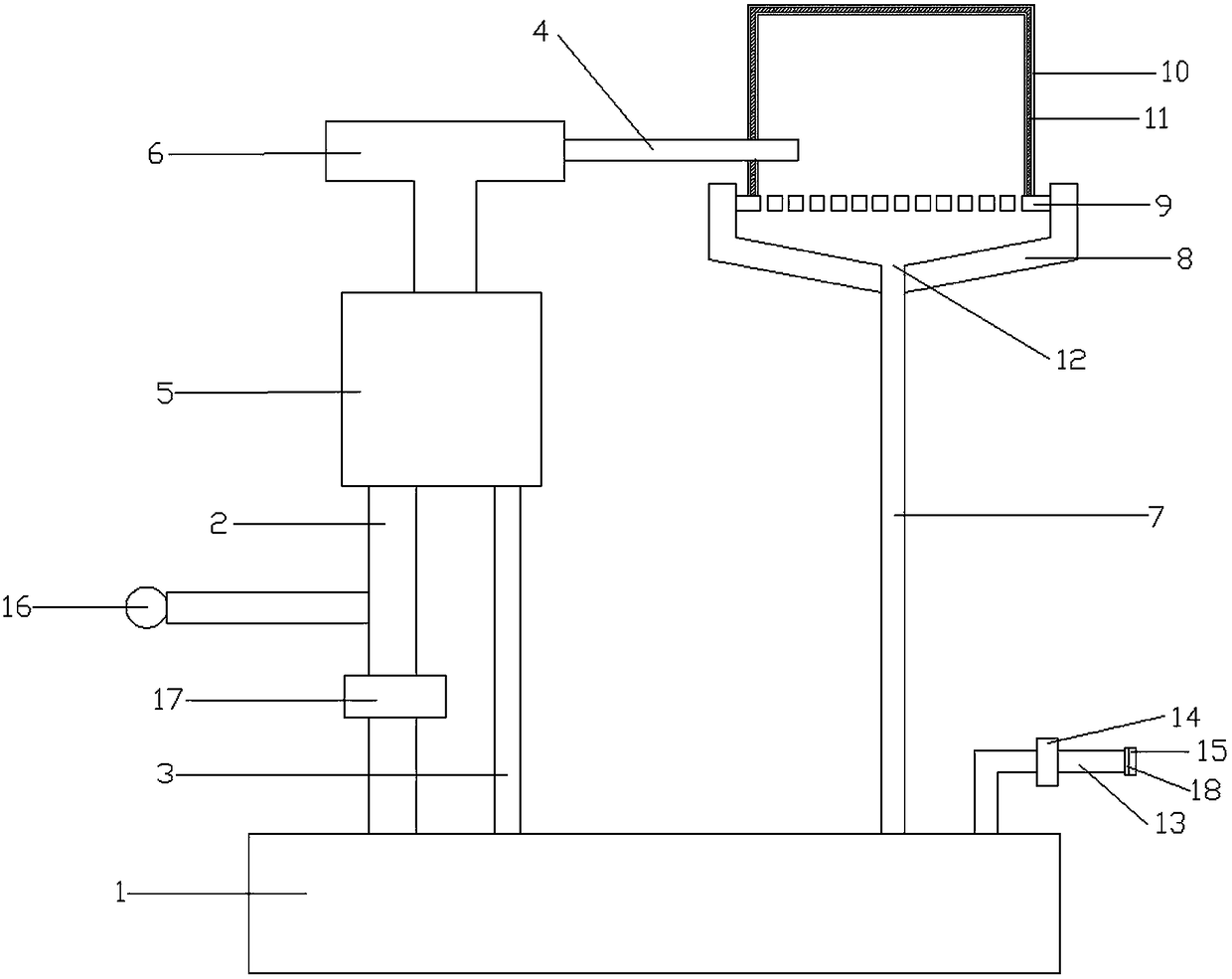

[0037] As the basic embodiment of the present invention, the present invention includes a turbine compressor oil tank flue gas recovery device, including an oil tank 1, a suction pipe 2, an oil return pipe 3, an exhaust pipe 4, an oil separator 5, a vacuum generator 6, Oil and gas filter device and second oil return pipe 7; the oil and gas filter device includes a support part 8, a leaky plate 9 and a filter, the support part 8 is in the shape of a groove, the leaky plate 9 is stuck in the groove, and the leaky plate 9 and the bottom of the support part 8 leave a gap; the filter is formed by connecting a plurality of side walls and a top, forming a cavity inside, and the bottom surface of the side wall is fixed to the upper surface of the drain plate 9; the side wall and the top It consists of two pieces of metal mesh 10 and a filter layer 11 filled between the two pieces of metal mesh 10; the cross section of the drain plate 9 is larger than the cross section of the filter; th...

Embodiment 2

[0039] As a preferred embodiment of the present invention, the present invention includes a turbine compressor oil tank flue gas recovery device, including oil tank 1, suction pipe 2, oil return pipe 3, exhaust pipe 4, oil separator 5, vacuum generator 6. Oil and gas filter device and second oil return pipe 7.

[0040] The oil-gas filtering device includes a support part 8, a leaky plate 9 and a filter, and the leaky plate 9 is provided with a number of holes; the support part 8 is square, with a groove in the middle, and the leaky plate 9 is square, and its size is the same as that of the groove. Matched, the interference fit is stuck in the groove, which is convenient for the leaky plate 9 and the support part 8 to be disassembled repeatedly, and is convenient to use; the said leaky plate 9 and the bottom of the groove leave a gap, which is convenient for the recovery of lubricating oil.

[0041] The filter is formed by connecting four side walls and a top, forming a cavity ...

Embodiment 3

[0046] As another preferred embodiment of the present invention, the present invention includes a turbine compressor oil tank flue gas recovery device, including oil tank 1, suction pipe 2, oil return pipe 3, exhaust pipe 4, oil separator 5, vacuum generating 6, an oil-gas filter device and a second oil return pipe 7; the oil-gas filter device includes a support part 8, a drain plate 9 and a filter, the support part 8 is in the shape of a groove, and the leak plate 9 is stuck in the groove, so There is a gap between the drain plate 9 and the bottom of the support portion 8; the filter is formed by connecting a plurality of side walls and a top, and a cavity is formed inside, and the bottom surface of the side wall is fixed to the upper surface of the drain plate 9; The wall and the top are respectively composed of two pieces of metal mesh 10 and a filter layer 11 filled between the two pieces of metal mesh 10; the cross section of the drain plate 9 is larger than the cross sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com