Waste material recycling device for micro-nano biomedical 3D printer

A 3D printer and biomedical technology, which is applied in the field of dental treatment equipment, can solve the problems of catheter waste and other problems, and achieve the effect of reducing cleaning, reducing work intensity, and facilitating collection and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

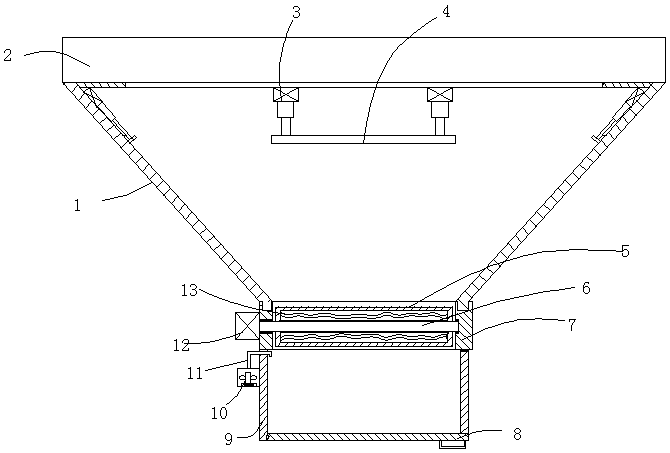

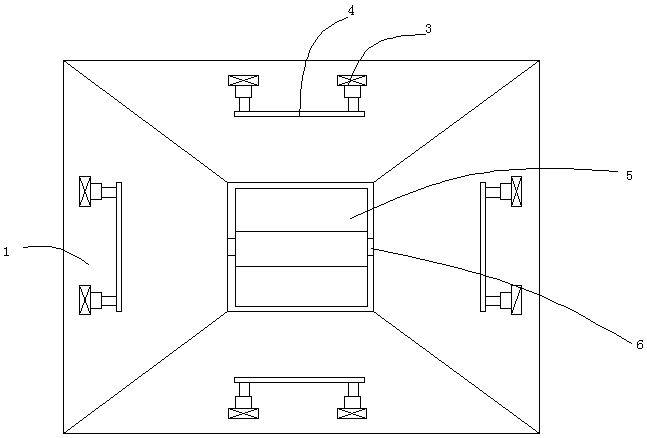

[0017] Examples, see Figure 1-2 , a waste recovery device for a micro-nano biomedical 3D printer, comprising a collection cylinder 1, a printer body 2 is fixedly connected to the top of the collection cylinder 1 through bolts, and a plurality of hydraulic cylinders 3 are fixedly connected to the periphery of the collection cylinder 1 through bolts. The output end of the cylinder 3 is fixedly connected with the cleaning plate 4 by bolts, the guide pipe 7 is threadedly connected with the lower part of the collection cylinder 1, and one side of the guide pipe 7 is connected with the motor 12 by bolts, and the output end of the motor 12 is fixed by a coupling A rotating shaft 6 is connected, and the other end of the rotating shaft 6 is rotationally connected with the guide pipe 7 through a bearing. The outer wall of the rotating shaft 6 is fixedly sleeved with a fan blade 5, and a heater 13 is embedded in the fan blade 5. The bottom of the guide pipe 7 A collection box 9 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com