Method for preparing laying hen feed through tea oil cold pressing cakes

A layer feed and oil cooling technology, applied in animal feed, animal feed, applications, etc., can solve the problem that effective substances cannot be effectively used, the laying performance of layers cannot be effectively improved, and Camellia oleifera seed meal cannot be directly used as feed, etc. problems, to achieve the effect of improving the fertilization rate and hatching rate of breeding eggs, good environmental and economic benefits, significant economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

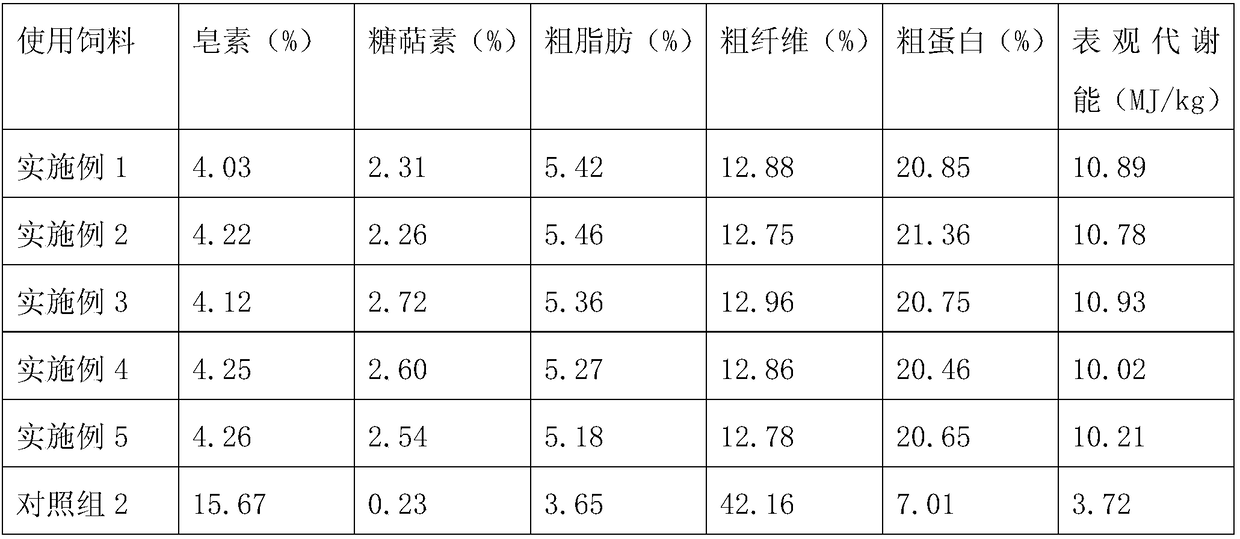

Examples

Embodiment 1

[0023] A kind of tea oil cold-pressed cake is made the method for laying hen feed, and this method comprises the steps:

[0024] (1) According to the 100kg tea oil cold-pressed cake, the 100kg tea oil cold-pressed cake is crushed into a mesh number of 100 mesh tea oil seed powder;

[0025] (2) adding 200 kg of water to tea oil seed powder, heating up to 50° C., adding 10 kg of methanol solution with a concentration of 65% under the condition of pH 9.0, and soaking for 2 hours to obtain a mixture;

[0026] (3) centrifuging the mixture obtained in step (2) to obtain an extract, and taking the filter residue for subsequent use;

[0027] (4) after adding 10kg concentration to the leaching liquid that step (2) obtains is 0.8% acetic acid, add 10kg concentration again and be the mixed liquor of 25% hydrogen peroxide mixing and stirring 5min, be 10% sodium hydroxide solution with concentration Adjusting the pH value of the mixed solution to 6.5, and then performing high vacuum conce...

Embodiment 2

[0034] A kind of tea oil cold-pressed cake is made the method for laying hen feed, and this method comprises the steps:

[0035] (1) According to the 100kg tea oil cold-pressed cake, the 100kg tea oil cold-pressed cake is broken into mesh number and be 105 mesh tea oil seed powder;

[0036] (2) adding 210 kg of water to tea oil seed powder, heating up to 52° C., adding 12 kg of methanol solution with a concentration of 67% under the condition of pH 10.0, and soaking for 2.5 hours to obtain a mixture;

[0037] (3) centrifuging the mixture obtained in step (2) to obtain an extract, and taking the filter residue for subsequent use;

[0038] (4) after adding 11kg concentration in the extract solution that step (2) obtains is 1.0% acetic acid, add 12kg concentration again and be the mixed liquor of 26% hydrogen peroxide mixing and stirring 6min, be 10% sodium hydroxide solution with concentration Adjusting the pH value of the mixed solution to 7.0, then performing high vacuum conc...

Embodiment 3

[0045] A kind of tea oil cold-pressed cake is made the method for laying hen feed, and this method comprises the steps:

[0046] (1) According to the 100kg tea oil cold-pressed cake, the 100kg tea oil cold-pressed cake is crushed into a mesh number of 110 mesh tea oil seed powder;

[0047] (2) adding 220 kg of water to tea oil seed powder, heating up to 54° C., adding 14 kg of methanol solution with a concentration of 69% under the condition of pH 11.0, and soaking for 3 hours to obtain a mixture;

[0048] (3) centrifuging the mixture obtained in step (2) to obtain an extract, and taking the filter residue for subsequent use;

[0049] (4) after adding 13kg concentration in the extract solution that step (2) obtains is 1.2% acetic acid, add 14kg concentration again and be the mixed liquor of 27% hydrogen peroxide mixing and stirring 7min, be 10% sodium hydroxide solution with concentration Adjusting the pH value of the mixed solution to 7.5, then performing high vacuum concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com