Manufacturing process of shoe soles and healthy shoes

A manufacturing process and healthy technology, applied to soles, footwear, insoles, etc., can solve problems such as low production efficiency, labor cost, and physical impact on workers, and achieve the effects of massage stimulation, magnetic therapy, and high support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

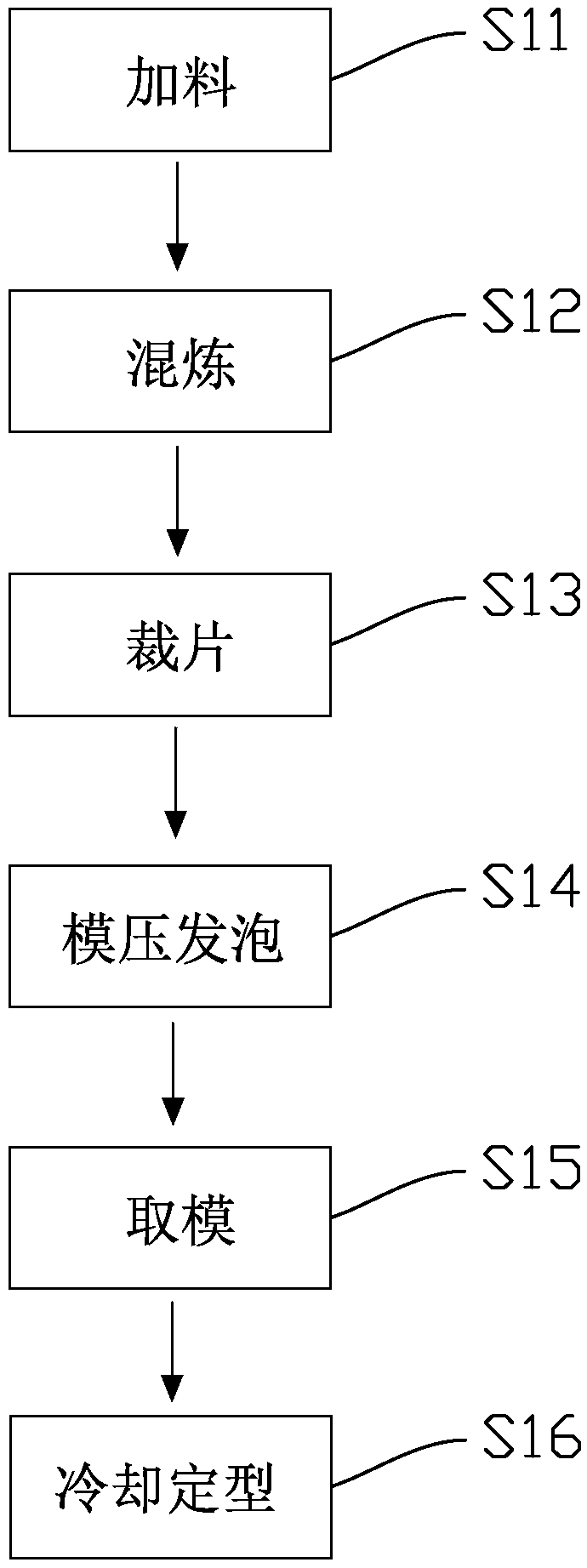

[0054] refer to figure 1 , a manufacturing process for shoe soles, comprising the following steps:

[0055] Step S11, feeding: set the temperature of the mill to 80°C to 90°C, after the temperature reaches, add EVA pellets;

[0056] Step S12, kneading: add stearic acid, zinc stearate and zinc oxide respectively when the material wraps the roll, turn the material 5-6 times, wait for the material to appear uniform white, then add the corresponding AC foaming agent and DCP cross-linking agent, after turning the material 4-5 times, the material will show a uniform light yellow color, then add the corresponding polyisobutylene, turn the material 7-8 times, and the film will come out;

[0057] Step S13, cutting pieces: cutting the sheets obtained in step S12 into uniform small pieces with the size of the mold cavity;

[0058] Step S14, molding and foaming: place the small piece cut in step S13 on a flat vulcanizer, and foam for 850 minutes at a temperature of 170° C. to 175° C. an...

Embodiment 2

[0078] refer to Figure 8 to Figure 12 , the present invention provides a healthy shoe, comprising a shoe body 01 and a shoe sole 02, the shoe sole 02 is made by the manufacturing process of a shoe sole described in Embodiment 1, and the shoe body 01 and the shoe sole 02 form a space for the wearer to wear. The wearing cavity 03 where the feet are inserted, the wearing cavity 03 is provided with a health care insole 04, the health care insole 04 includes a bottom layer 2 of an elastic material and a surface layer 1 of a breathable material, and the bottom layer 2 is fixed to the surface layer 1 , the Chinese medicine layer 3 is arranged between the bottom layer 2 and the surface layer 1 . The Chinese medicine layer 3 is a paper material or cloth containing medicines, and the prescription of the medicines includes: 30g of astragalus, 20g of mulberry, 20g of wild chrysanthemum, 20g of kudzu root, 20g of red peony, 20g of Achyranthes bidentata, 20g of Prunella vulgaris, 15g of Ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com