Hydrogen removal device for marine electrolytic ballast water treatment system

An electrolytic compression and management system technology, which is applied in the field of hydrogen treatment devices for flammable and explosive by-products, can solve the problems of difficult installation, long hydrogen exhaust pipelines, and high equipment costs, and achieve improved efficiency, low cost, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

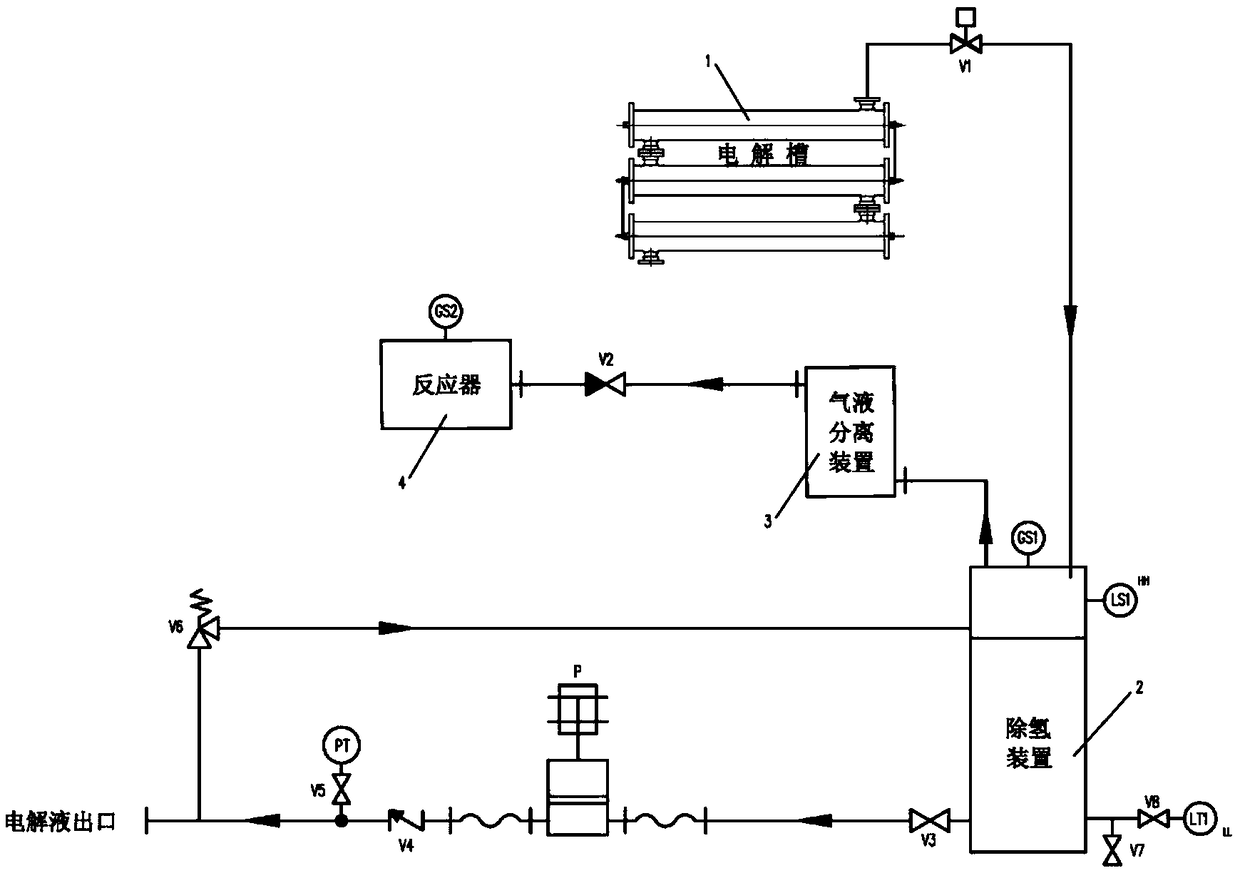

[0020] see figure 1 , The present invention is a treatment device for by-product hydrogen in the treatment process of ship electrolysis ballast water management system, which is characterized in that it includes an electrolytic cell 1, a hydrogen removal device 2, a gas-liquid separation device 3, and a reactor 4 connected in sequence. The outlet of the existing seawater electrolysis device 1 discharge (containing hydrogen) electrolyte is connected with the inlet of the dehydrogenation device 2, and the upper gas outlet of the dehydrogenation device 2 is connected with the inlet of the gas-liquid separation device 3, and the gas-liquid separation device 3 The gas outlet of is connected with the inlet of reactor 4 through a check valve V2. The reactor is equipped with a resistance heating device, a temperature control device, and a temperature real-time monitoring sensor. In the figure, the automatic valve V1 sequentially connected to the seawater introduction pipeline is a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com