Material special for pipes and preparation method of material

A technology for special materials and crushing materials for pipes, applied in applications, household appliances, tubular objects, etc., can solve the problems of affecting the natural environment, human health, unable to meet the needs of consumers, low recycling rate of waste plastics, etc., and achieve significant economic benefits. and environmental benefits, innovative ideas, simple processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

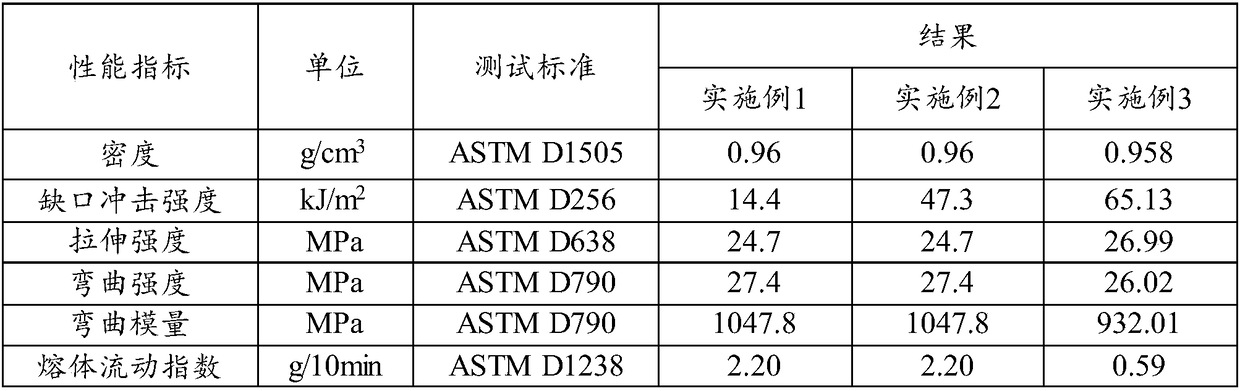

Examples

preparation example Construction

[0021] The present invention provides a kind of preparation method of pipe special material, comprises the following steps:

[0022] a) After cleaning the recovered waste polyethylene, crush it to obtain polyethylene crushed material;

[0023] b) After mixing the broken polyethylene material obtained in step a) with a crosslinking agent and calcium carbonate, extruding and granulating to obtain special materials for pipes.

[0024] In the invention, firstly, the recovered waste polyethylene is washed and crushed to obtain broken polyethylene materials. In the present invention, the recovered waste polyethylene is a solid waste with a wide range of sources, and the present invention has no special limitation on its sources. In a preferred embodiment of the present invention, the recycled waste polyethylene is recycled waste polyethylene bottle cap material.

[0025] In the present invention, the purpose of the cleaning is to remove sundries and dust on the recycled waste poly...

Embodiment 1

[0046] (1) Wash the polyethylene bottle cap material with water, remove sundries and dust, and crush it into materials of similar size to obtain polyethylene crushed material with a particle size of 6 mm to 9 mm; the melt flow index of the polyethylene crushed material is detected It is 8g / 10min.

[0047] (2) fully stir the calcium carbonate of 0.1 weight part dicumyl peroxide and 0.4 weight part in high-speed mixer for 3min, the rotating speed of described high-speed mixer is 250rpm; The ethylene crushed material was continuously stirred for 3 minutes to obtain a mixed material.

[0048] (3) The mixture obtained in step (2) was extruded and granulated in a twin-screw extruder at a temperature of 190° C. and a screw speed of 200 rpm to obtain a special material for pipes.

Embodiment 2

[0050] (1) Wash the polyethylene bottle cap material with water, remove sundries and dust, and crush it into materials of similar size to obtain polyethylene crushed material with a particle size of 6 mm to 9 mm; the melt flow index of the polyethylene crushed material is detected It is 8g / 10min.

[0051] (2) the dicumyl peroxide of 0.25 weight part and the calcium carbonate of 1 weight part are fully stirred 3min in high-speed mixer, and the rotating speed of described high-speed mixer is 300rpm; The ethylene crushed material was continuously stirred for 3 minutes to obtain a mixed material.

[0052] (3) The mixture obtained in step (2) was extruded and granulated in a twin-screw extruder at a temperature of 190° C. and a screw speed of 200 rpm to obtain a special material for pipes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com