Polyethylene plastic greenhouse cloth and preparation method thereof

A polyethylene plastic, polyethylene technology, applied in the direction of stretch spinning, weaving, fabrics, etc., can solve the problems of increasing farmers' costs, short service life, reduced light transmittance, etc., achieving low cost, long service life, attenuation slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A polyethylene plastic greenhouse cloth, the greenhouse cloth is a three-layer composite structure, the three-layer composite structure includes an outer layer, a middle layer and an inner layer; the outer layer and the inner layer are both high-pressure low-density polyethylene coating layers; the middle layer is a low-pressure High-density polyethylene woven cloth.

[0025] The outer layer in this embodiment includes the following components in parts by mass: 80 to 90 parts of polyethylene, 10 to 20 parts of an anti-aging mixture containing an infrared blocking agent; the middle layer includes the following components in parts by mass: polyethylene 92 ~100 parts, anti-aging agent 2-6 parts; the inner surface layer includes the following components in mass parts: 83-89 parts of polyethylene, 11-17 parts of anti-aging mixture containing anti-fogging agent.

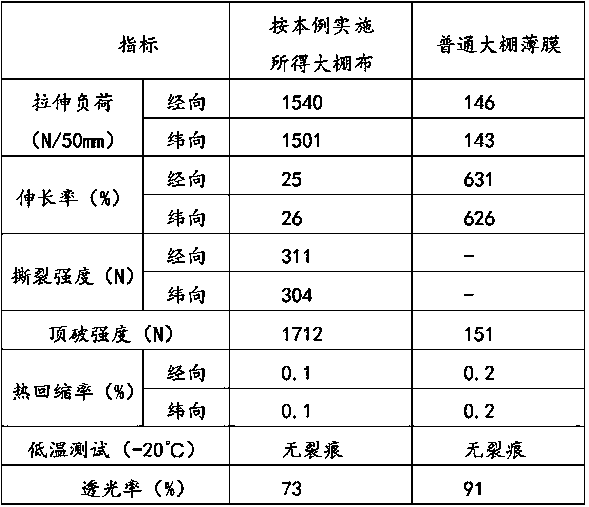

[0026] The greenhouse cloth of the present invention has a three-layer composite structure, high strength, good w...

Embodiment 2

[0028] This embodiment is basically the same as Embodiment 1, the difference is:

[0029] The outer layer includes the following components in parts by mass: 86 parts of polyethylene, 14 parts of anti-aging mixture containing infrared blocking agent.

Embodiment 3

[0031] This embodiment is basically the same as Embodiment 1, the difference is:

[0032] The middle layer includes the following components in parts by mass: 96 parts of polyethylene and 4 parts of anti-aging agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com