Stainless steel connecting element for prefabricated sandwich heat insulation wall board, heat insulation wall board and construction method thereof

A technology of thermal insulation wallboard and stainless steel, which is applied in the direction of manufacturing tools, building components, ceramic molding machines, etc., can solve the problems of poor anchorage performance of FRP tie parts, poor fixation of steel mesh, and heavy fixing workload, etc., so as to facilitate temporary Fixing, improving the convenience of construction, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

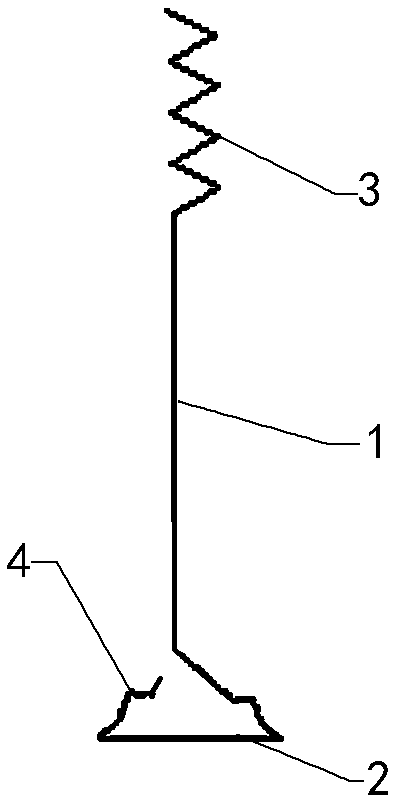

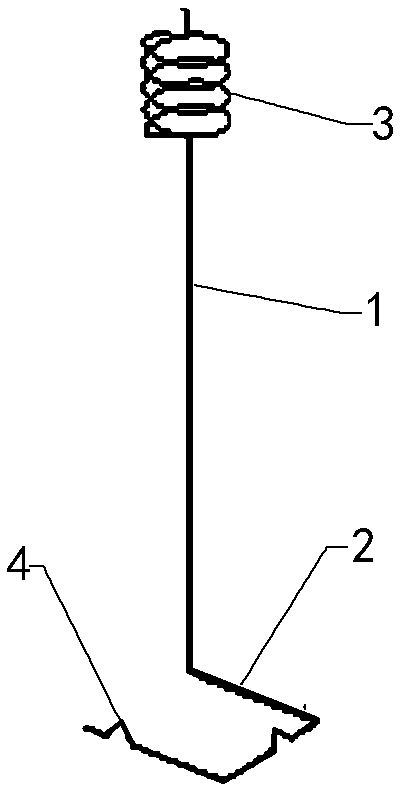

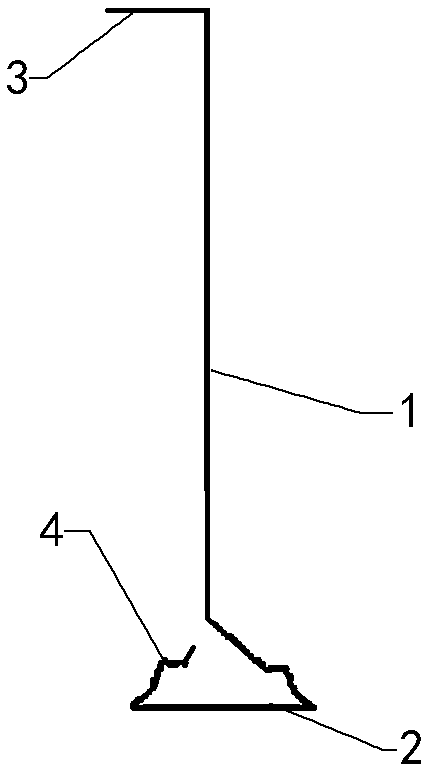

[0042] Such as Figure 1 to Figure 7 As shown, the stainless steel connector for prefabricated sandwich thermal insulation wall panels of the present invention includes a connecting body 1, a first anchoring segment 2 and a second anchoring segment 3 respectively located at both ends of the connecting body 1, the first anchoring segment 2, the second anchoring segment 3 and The connecting body 1 is made in one piece, and the first anchoring section 2 and the second anchoring section 3 are both made by mechanical bending process.

[0043] The connecting body 1 is a solid stainless steel rod with a diameter of 2-6mm, which is perpendicular to the surface of the wallboard and arranged in the wallboard insulation layer 5 .

[0044] The first anchoring section 2 is a polygonal structure with an opening formed by continuous bending of stainless steel rods at least twice, one end is connected to the end of the connecting body 1, set perpendicular to the connecting body 1, and inserte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com