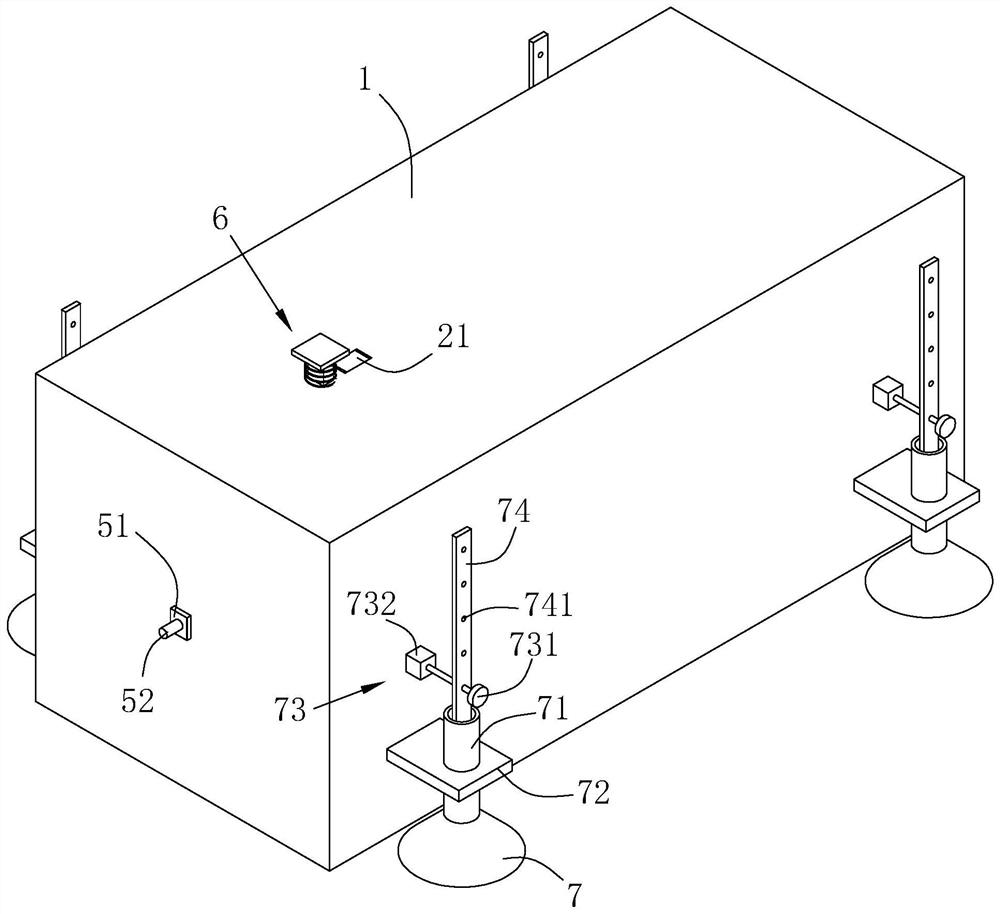

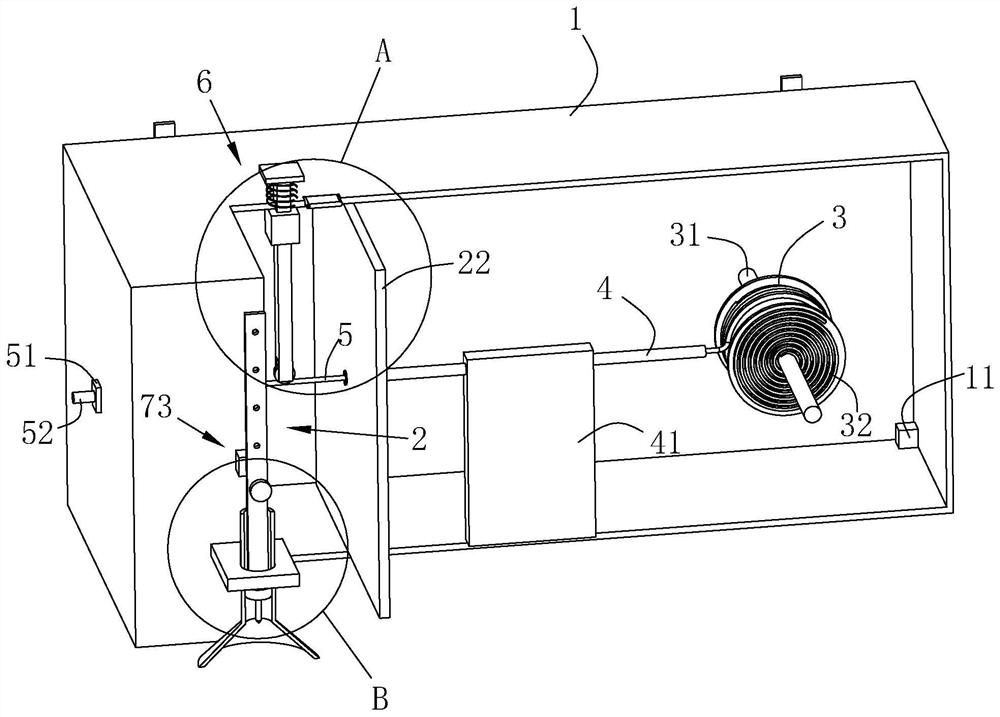

Engineering measurement and pay-off device

A pay-off device and engineering surveying technology, which is applied to measuring devices, surveying instruments, surveying and navigation, etc., can solve the problems of reduced service life of the pay-off device, poor rotation of the wire wheel, pollution of the wire wheel toner, etc., and achieve improvement Service life, wear reduction, wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

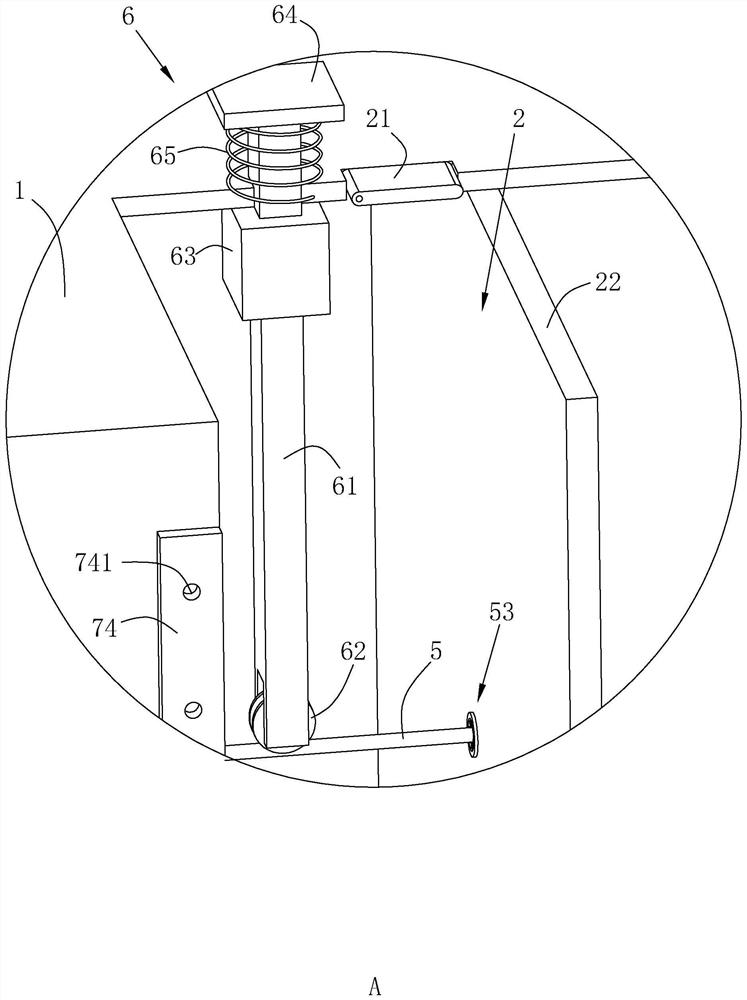

Examples

preparation example Construction

[0066] The preparation method of ink line 5 is as follows:

[0067] Add natural rubber to the open mill, roll speed 30r / min, roll distance 5mm, and masticate for 30s; add silica and silane coupling agent, roll speed 30r / min, roll distance 4mm, and knead for 60s; add oil, hard Sodium fatty acid and ceramic powder, roll speed 45r / min, roll distance 3.5mm, knead for 45s; add paraffin, roll speed 45r / min, roll distance 3mm, knead for 45s, add sulfur and accelerator, roll speed 45r / min , the roller distance is 2mm, the mixing is 30s, the roller speed is 60r / min, the roller distance is 1.5mm, the mixing is 45s, and the rubber is discharged to form a mixed rubber.

[0068] Put the mixed rubber into the screw extruder to extrude the unvulcanized ink line 5, then put the unvulcanized ink line 5 into the oven to heat and cross-link to form the ink line 5, the vulcanization temperature is 150°C, the nitrogen pressure is 10MPa, and the vulcanization time is 30min.

[0069] Friction tube...

Embodiment 2

[0090] Ink line 5 includes the following components in parts by mass:

[0091] 100 parts of natural rubber; 12 parts of oil; 23 parts of paraffin; 45 parts of white carbon black; 8 parts of sodium stearate; 4 parts of ceramic powder; 4 parts of silane coupling agent; 2 parts of sulfur; 1 part of accelerator.

[0092] Friction tube 4 includes the following components in parts by mass:

[0093] 100 parts of polytetrafluoroethylene; 4 parts of silane coupling agent; 18 parts of corundum.

Embodiment 3

[0095] Ink line 5 includes the following components in parts by mass:

[0096] 100 parts of natural rubber; 15 parts of oil; 25 parts of paraffin; 50 parts of white carbon black; 10 parts of sodium stearate; 5 parts of ceramic powder; 5 parts of silane coupling agent; 3 parts of sulfur; 2 parts of accelerator.

[0097] Friction tube 4 includes the following components in parts by mass:

[0098] 100 parts of polytetrafluoroethylene; 5 parts of silane coupling agent; 20 parts of corundum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com