Split type diameter expanded lead for extra high tension onsite test

A technology of splitting wires and expanding diameter wires, applied in conductors, insulated conductors, testing dielectric strength, etc., can solve the problem of threats to the safety of the tested equipment and testers, the large wind load of aluminum foil expanded diameter wires, and the difficulty of applying partial discharge. Test and other issues to achieve the effect of ensuring strength, excellent tensile strength and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

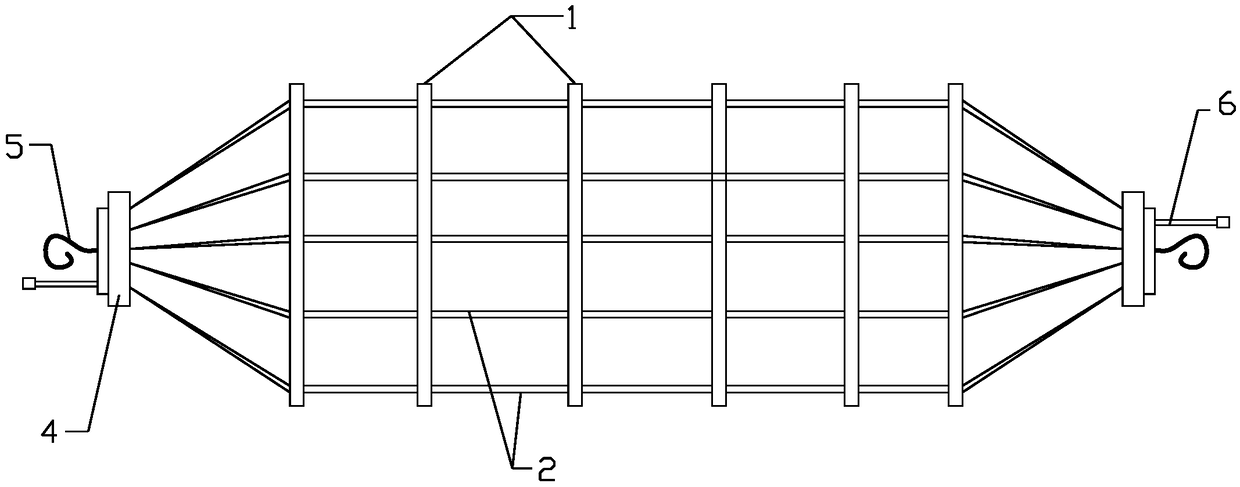

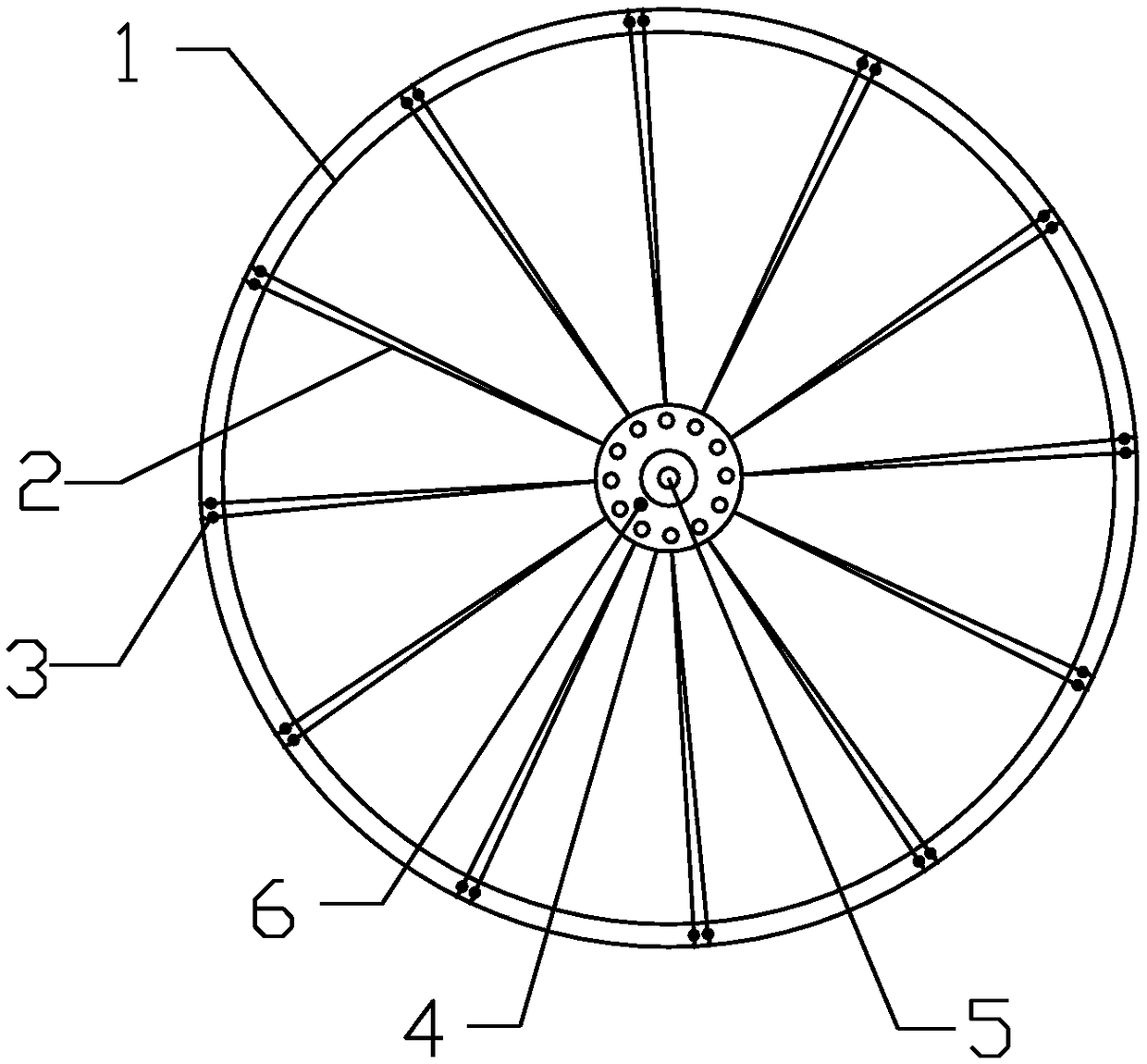

[0038] Such as figure 1 and figure 2 A split-type expanded-diameter conductor used in UHV field tests shown is characterized in that: the split-expanded-diameter conductor includes at least two spacer discs 1 and multiple groups of split-diameter conductors, and the spacer discs 1 are pipe diameters The ring diameter is 550-600mm made of 16-18mm hollow aluminum tube, and the distance between the spacers 1 distributed on the split wires is 0.8-2m, and the optimal distance is 1-1.5m. There are 8 to 16 groups of split wires, each group of split wires is composed of 2 to 4 sub-wires 2, and the radius of each sub-wire 2 is 1 mm to 1.5 mm; ~16 groups, and 8~16 groups of split wire perforations are equidistantly distributed on the position near the outer edge of the spacer plate 1. Each group of split wire perforations includes 2 to 4 sub-conductor holes 3 with a spacing of 5-10 mm. Each sub-conductor hole The aperture of 3 is equal to the diameter of wire 2. Each sub-wire in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com