A metal mesh structure and touch screen

A metal grid and grid technology, applied in the field of flat panel display, can solve problems affecting the normal function of the touch screen, poor static electricity intersection, weak antistatic of a single line, etc., to improve the optical difference problem, avoid interlayer electrostatic interference, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to explain the metal grid and the touch screen provided by the present invention, a detailed description will be given below in conjunction with the drawings and the text description of the embodiments.

[0043] The invention provides a metal grid structure with no signal interference between signal circuits, extremely weak metal reflective stripes and good optical performance, and a touch screen adopting the metal grid structure.

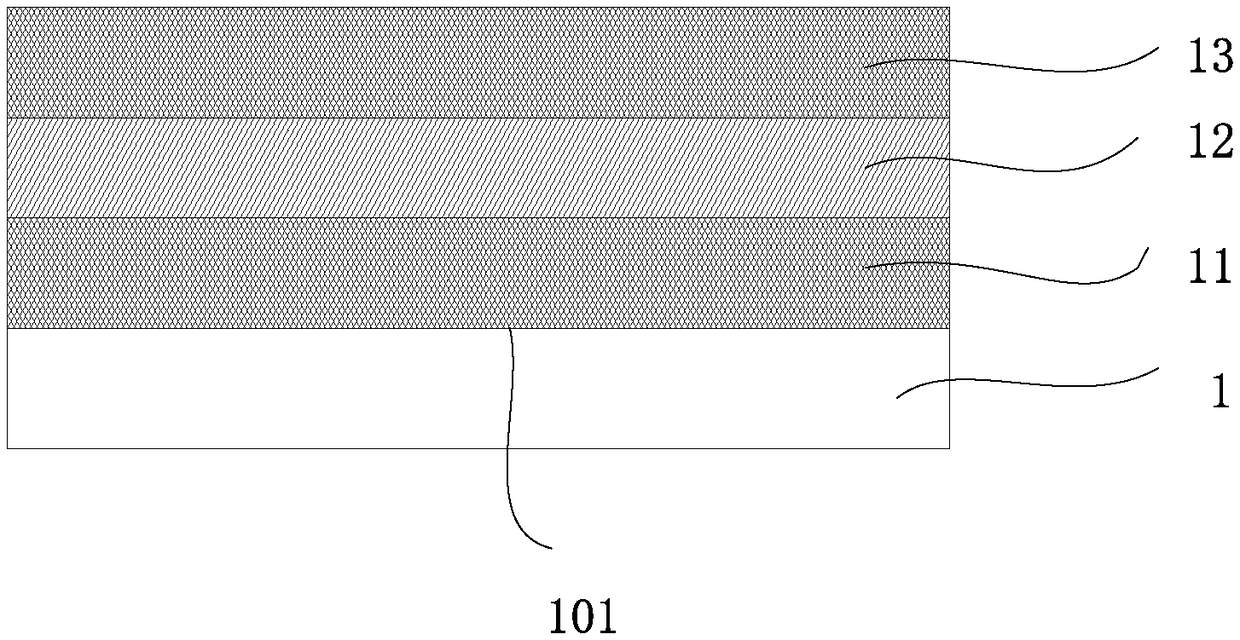

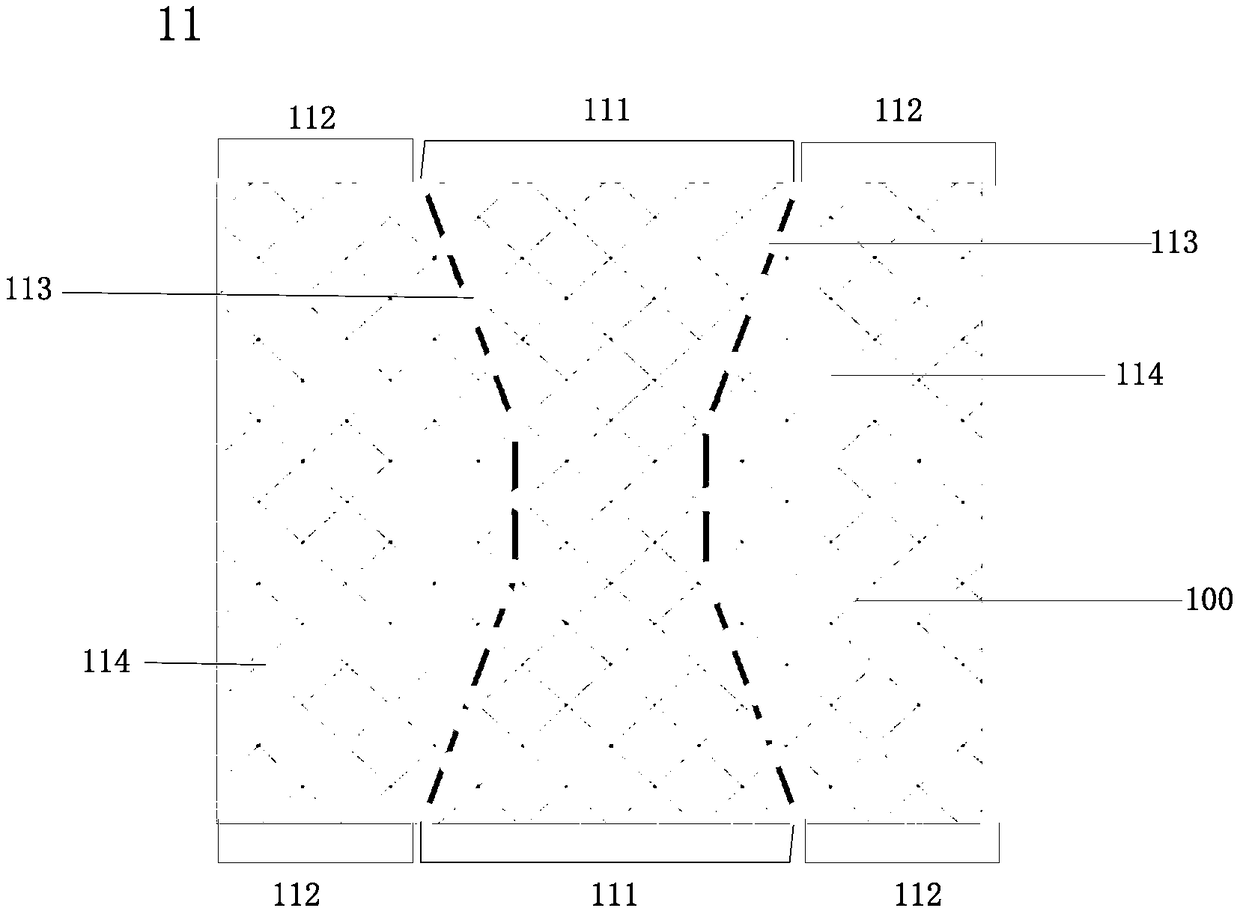

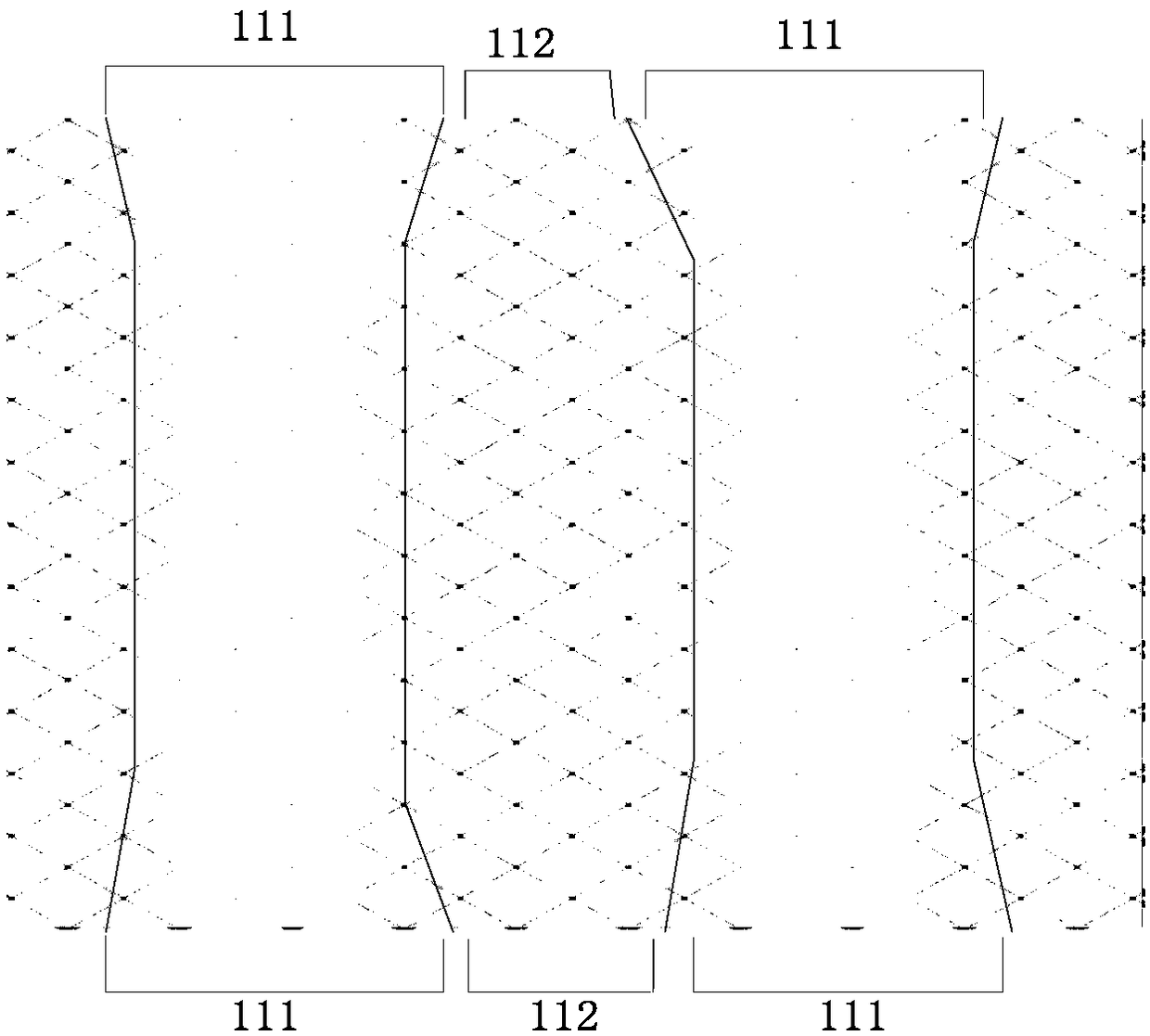

[0044] Such as figure 1 As shown, the metal mesh structure provided by the embodiment of the present invention is disposed on a substrate 1 made of glass or film of a touch screen, and the substrate 1 has at least a first surface 101. The metal mesh structure is formed by stacking a plurality of film layers for realizing different functions, including: a first touch electrode 11 formed by a plurality of metal mesh lines 100 arranged on the first surface 101; On the first touch electrode 11, the insulating layer 12 on the surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com