A kind of lithium-sulfur battery polymer barrier layer material and preparation method

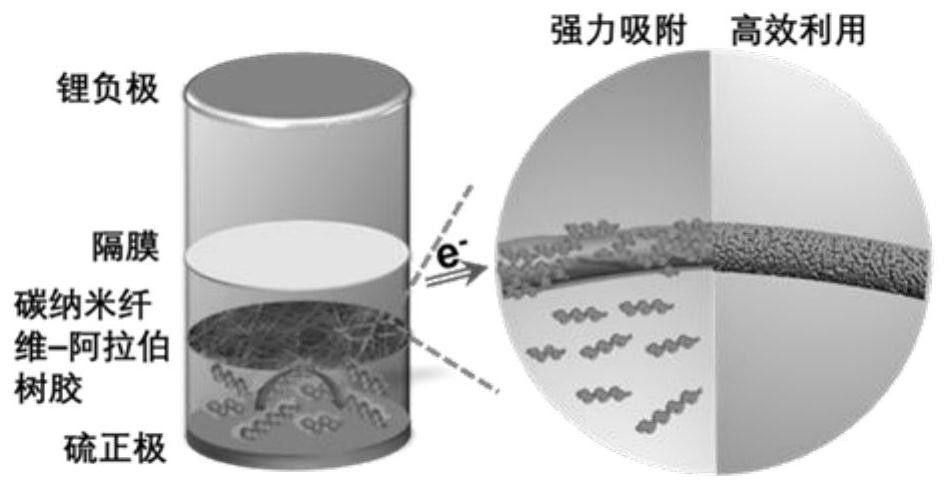

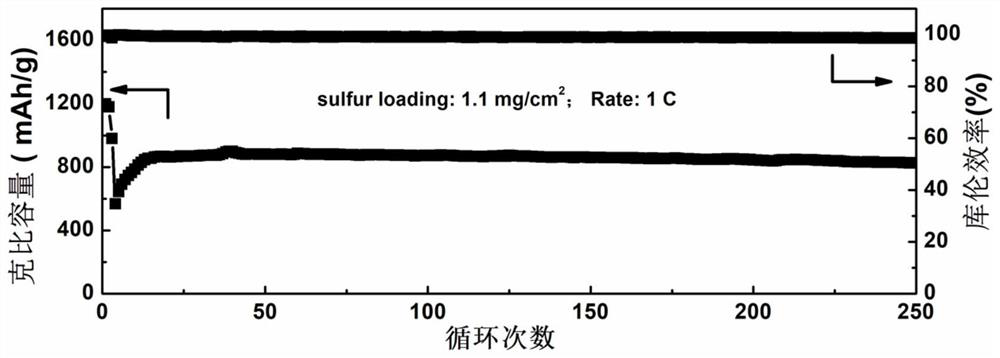

A lithium-sulfur battery and polymer technology, applied in the field of electrochemical energy storage, can solve the problems of complicated operation and expensive raw materials, and achieve the effects of simple operation, cheap raw materials, and excellent anti-self-discharge capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) The carbon nanofiber membrane is made by electrospinning technology, prepare 3mg / ml polyacrylonitrile N,N-dimethylformamide solution, and suck it into the syringe as the spinning solution for electrospinning process; The silk equipment uses a voltage of 15kV, the distance between the syringe and the collector is adjusted to 15cm, and the required polyacrylonitrile membrane precursor is prepared after 2h.

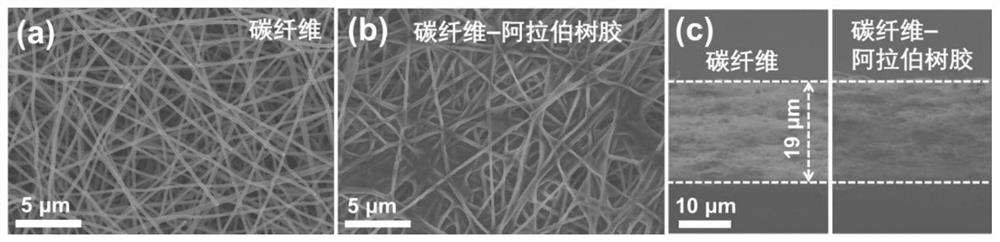

[0034] (2) Put the polyacrylonitrile membrane precursor in a tube furnace, pretreat it in an air atmosphere at 280°C for 3h, then change it to a nitrogen atmosphere to carbonize it at 800°C for 2h to obtain the required carbon nanofiber membrane and cut it Into a round piece with a diameter of 1.4cm, its thickness is 25μm, and its mass is 0.2772mg, so its composite film mass is 0.18mg / cm 2 .

[0035] (3) Gum arabic was dissolved in distilled water to prepare a 7mg / ml solution.

[0036] (4) According to the mass ratio of carbon nanofiber membrane and gum arabic at 1:1, d...

Embodiment 2

[0039] (1) Dissolve polyacrylonitrile in N,N-dimethylformyl solvent, prepare a 2mg / ml polyacrylonitrile solution, and prepare polyacrylonitrile film precursors by electrospinning;

[0040] (2) Carbonize the polyacrylonitrile membrane precursor in nitrogen atmosphere at 900°C for 2.5 hours to obtain the required carbon nanofiber membrane, which is cut into circular pieces with a diameter of 1.6cm, with a thickness of 19μm and a mass of 0.3 mg, so its surface mass is 0.15mg / cm 2 .

[0041] (3) The gum arabic was dissolved in distilled water to prepare a 5 mg / ml solution.

[0042] (4) According to the mass ratio of carbon nanofiber membrane to gum arabic at 1.5:1, drop 40 μl of gum arabic solution on the carbon nanofiber membrane;

[0043] (5) Vacuum drying at 70°C for 20 hours, other conditions are as in Example 1, the thickness of the carbon nanofiber-gum arabic composite film prepared is 19 μm, and the composite film mass is 0.25 mg / cm 2 .

Embodiment 3

[0045] (1) Dissolve polyacrylonitrile in N,N-dimethylformyl solvent, prepare a solution of 1mg / ml polyacrylonitrile, and prepare polyacrylonitrile film precursor by electrospinning;

[0046] (2) Carbonize the polyacrylonitrile membrane precursor in nitrogen atmosphere at 1000°C for 3 hours to obtain the required carbon nanofiber membrane, which is cut into circular pieces with a diameter of 1.5cm, with a thickness of 17μm and a mass of 0.21mg , So its mass is 0.12mg / cm 2 .

[0047] (3) The gum arabic was dissolved in distilled water to prepare a 4 mg / ml solution.

[0048] (4) According to the mass ratio of carbon nanofiber membrane and gum arabic at 2:1, drop 28.7 μl of gum arabic solution on the carbon nanofiber membrane;

[0049] (5) Vacuum drying at 80°C for 16 hours, other conditions are as in Example 1. The thickness of the prepared carbon nanofiber-gum arabic composite film is 17 μm, and the composite film mass is 0.18 mg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com