Graphene coating electrothermal needle for high-efficiency heat production

A technology of graphene and electric heating needles, which is applied in the field of medical devices to achieve the effects of convenient mass production, high heat production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

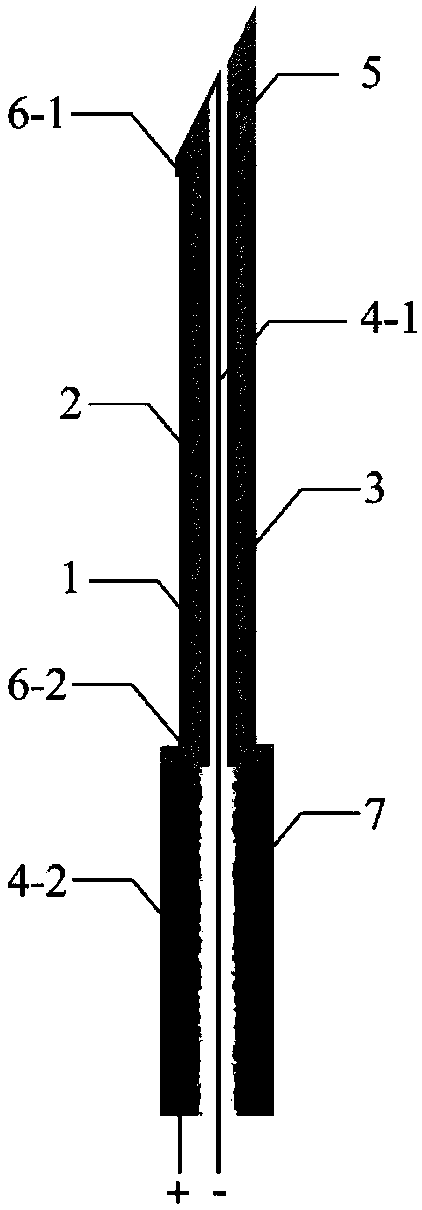

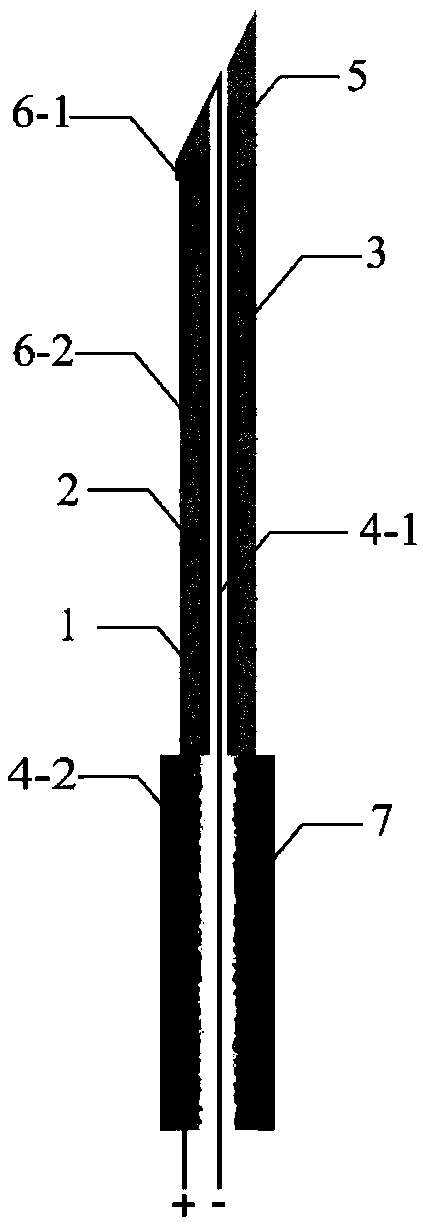

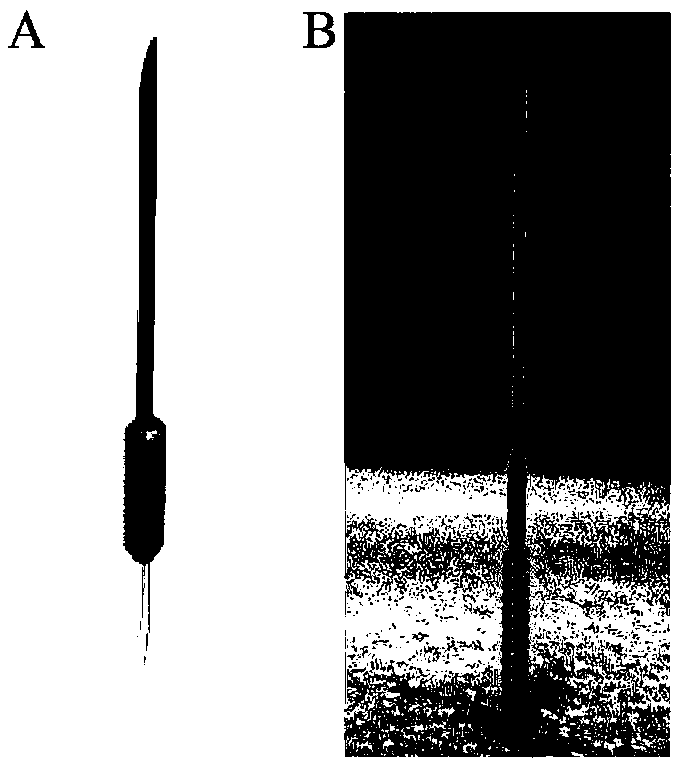

Method used

Image

Examples

Embodiment 1

[0043] The insulation and thermal insulation coating 2 is attached to the surface of the hollow needle body 1 through the following steps:

[0044] (1) Choose a needle point integrated stainless steel hollow needle body 1 with a length of 80 mm, an inner diameter of 0.5 mm, an outer diameter of 0.8 mm, and a first inclination angle of the needle tip of 9°. The hollow needle body 1 is polished with fine sandpaper to remove impurities, and then used The mixed acid solution is corroded for 1 minute, and the mixed acid solution is concentrated hydrochloric acid with a mass fraction of 38%: concentrated nitric acid with a mass fraction of 68%: water volume ratio = 10:1:10;

[0045] (2) The nano-silica gel coating of 1 weight part is mixed with the water of 1 weight part to obtain mixed solution, the hollow needle body 1 after processing is immersed in the mixed solution for 5 minutes, then by dipping and pulling method on the needle body surface Form a film and dry it in an oven at...

Embodiment 2

[0054] The insulation and thermal insulation coating 2 is attached to the surface of the hollow needle body 1 through the following steps:

[0055] (1) Choose a silver hollow needle with a length of 100mm, an inner diameter of 0.2mm, an outer diameter of 0.4mm, and a needle tip with a first inclination angle of 11°, remove impurities by grinding with fine sandpaper, and then use a mixed acid solution (mass fraction 38% concentrated hydrochloric acid: mass fraction 68% concentrated nitric acid: water=10:1:10) corrosion for 2 minutes;

[0056] (2) 1 weight part of nano-silica gel coating is mixed with 5 weight parts of water, the needle body is immersed in the mixed solution for 5 minutes, and then a thin film is formed on the surface of the needle body by dipping and pulling method, and it is dried in an oven at 80 ° C. Dry in medium for 5 hours to form a film;

[0057] (3) Repeat the above 5 times to obtain an insulating and heat-insulating coating with a thickness of 100 μm ...

Embodiment 3

[0066] The insulation and thermal insulation coating 2 is attached to the surface of the hollow needle body 1 through the following steps:

[0067] (1) Choose a needle-point integrated gold hollow needle tube with a length of 100 mm, an inner diameter of 0.4 mm, an outer diameter of 0.9 mm, and a needle point with a first inclination angle of 17°. Polish it with fine sandpaper to remove impurities, and then use a mixed acid solution (mass. Fraction 38% concentrated hydrochloric acid: mass fraction 68% concentrated nitric acid: water = 10:1:10) corrosion for 1 minute;

[0068] (2) 1 weight part of nano-silica gel coating is mixed with 5 weight parts of water, the needle body is immersed in the mixed solution for 5 minutes, and then a thin film is formed on the surface of the needle body by dipping and pulling method, and it is dried in an oven at 80 ° C. Dry in medium temperature for 5 hours to form a film to obtain an insulating coating with a thickness of 20 μm and a length o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com