Organic waste gas recovery and treatment system and method

A technology for organic waste gas recovery and treatment, applied in gas treatment, combustion methods, separation methods, etc., can solve the problems of polluting outdoor air, affecting human health, environmental pollution, etc., and achieves high processing efficiency, low use cost, and low maintenance cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

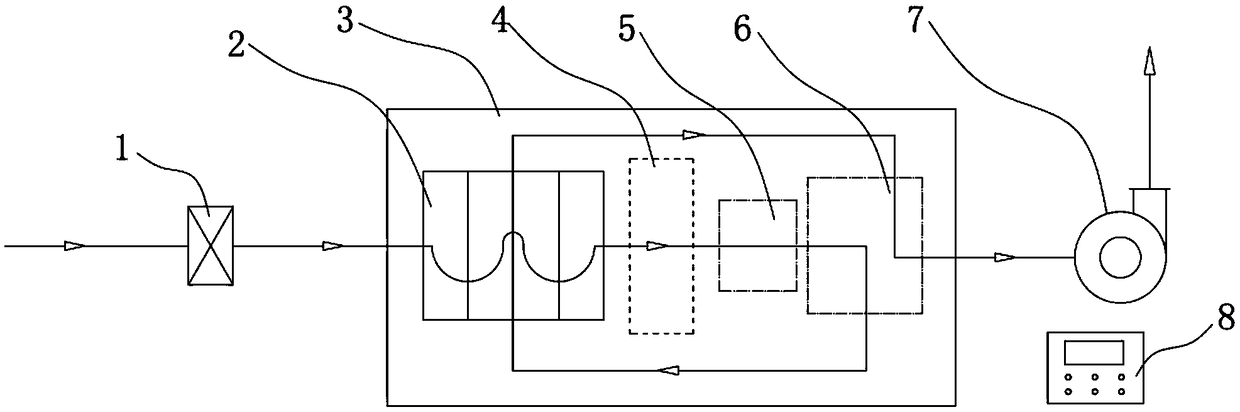

[0019] The organic waste gas recovery and treatment system and its process flow of the present invention will be further described below in conjunction with the accompanying drawings.

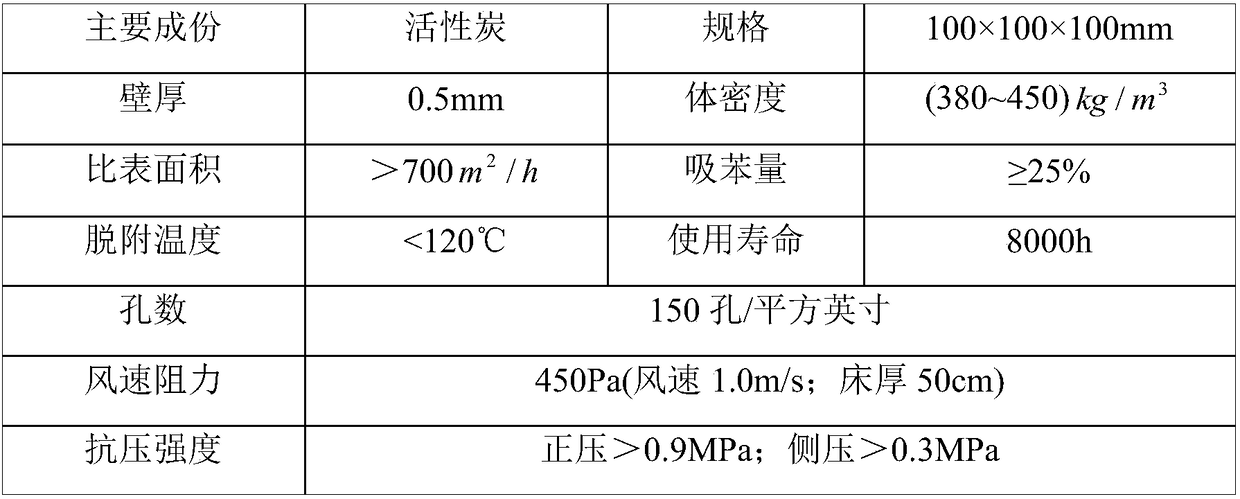

[0020] The main pollutants of exhaust gas produced during painting are benzene, toluene, xylene and non-methane total hydrocarbons, and the concentration is generally 250mg / m 3 Within, the temperature is normal temperature, the present invention designs a kind of organic waste gas recycling treatment system, see figure 1 , including a filter box, an adsorption device and a catalytic oxidation device. The organic waste gas passes through the filter box to remove particles and dust, and then the waste gas enters the adsorption device and is adsorbed and purified by activated carbon filled on both sides. The gas after adsorption can be directly discharged up to the standard. After the activated carbon is saturated Hot air desorption regeneration is adopted, and the desorbed high-concentration orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com