Anti-corrosion coating brush printing device for electronic chip

A technology for anti-corrosion coatings and electronic chips, applied in coatings, devices for coating liquid on surfaces, etc., can solve the problems of poor brushing thickness, uneven brushing, low efficiency, etc., and achieve better brushing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

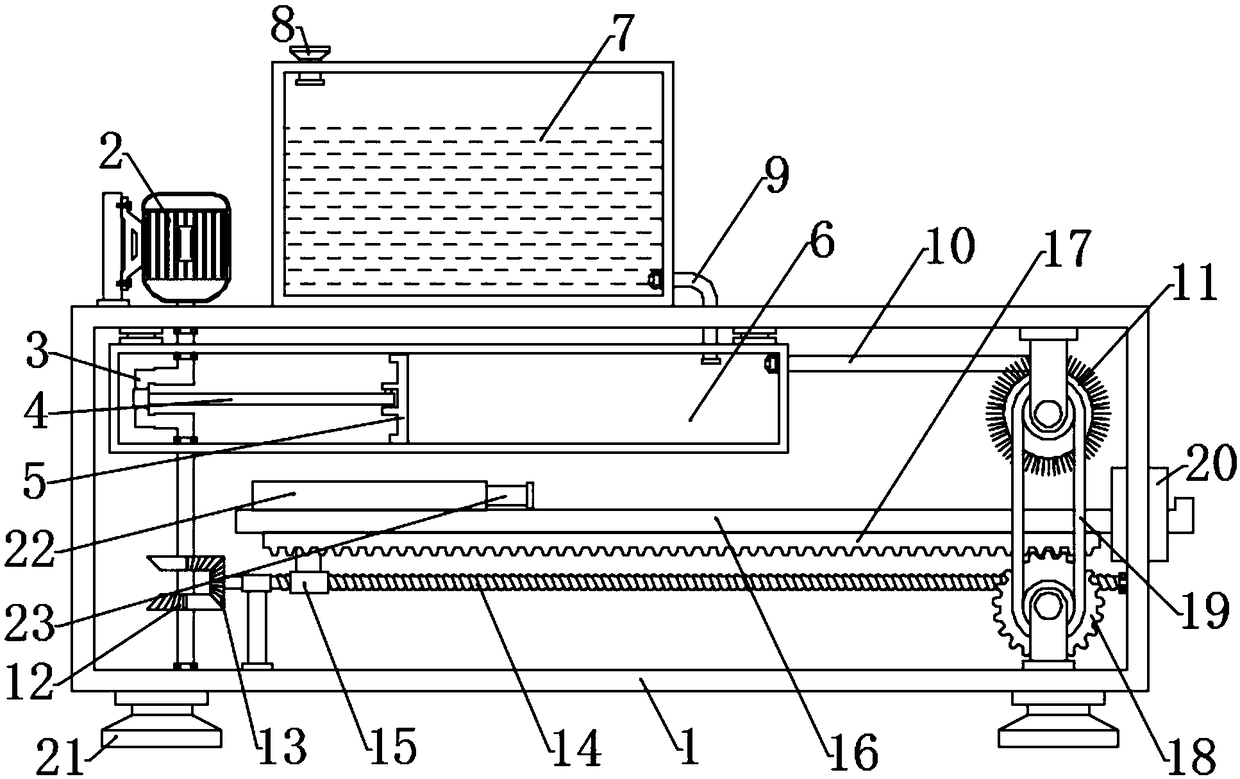

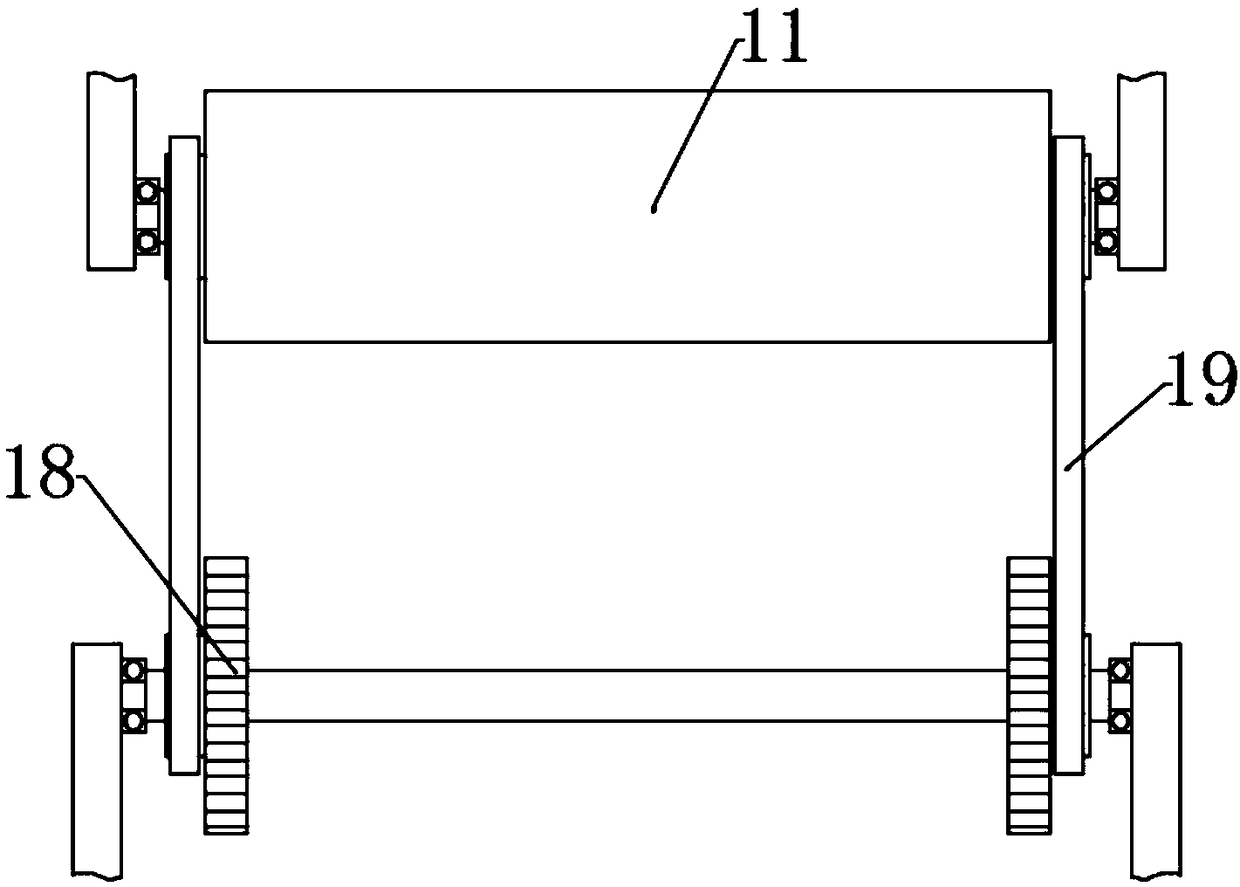

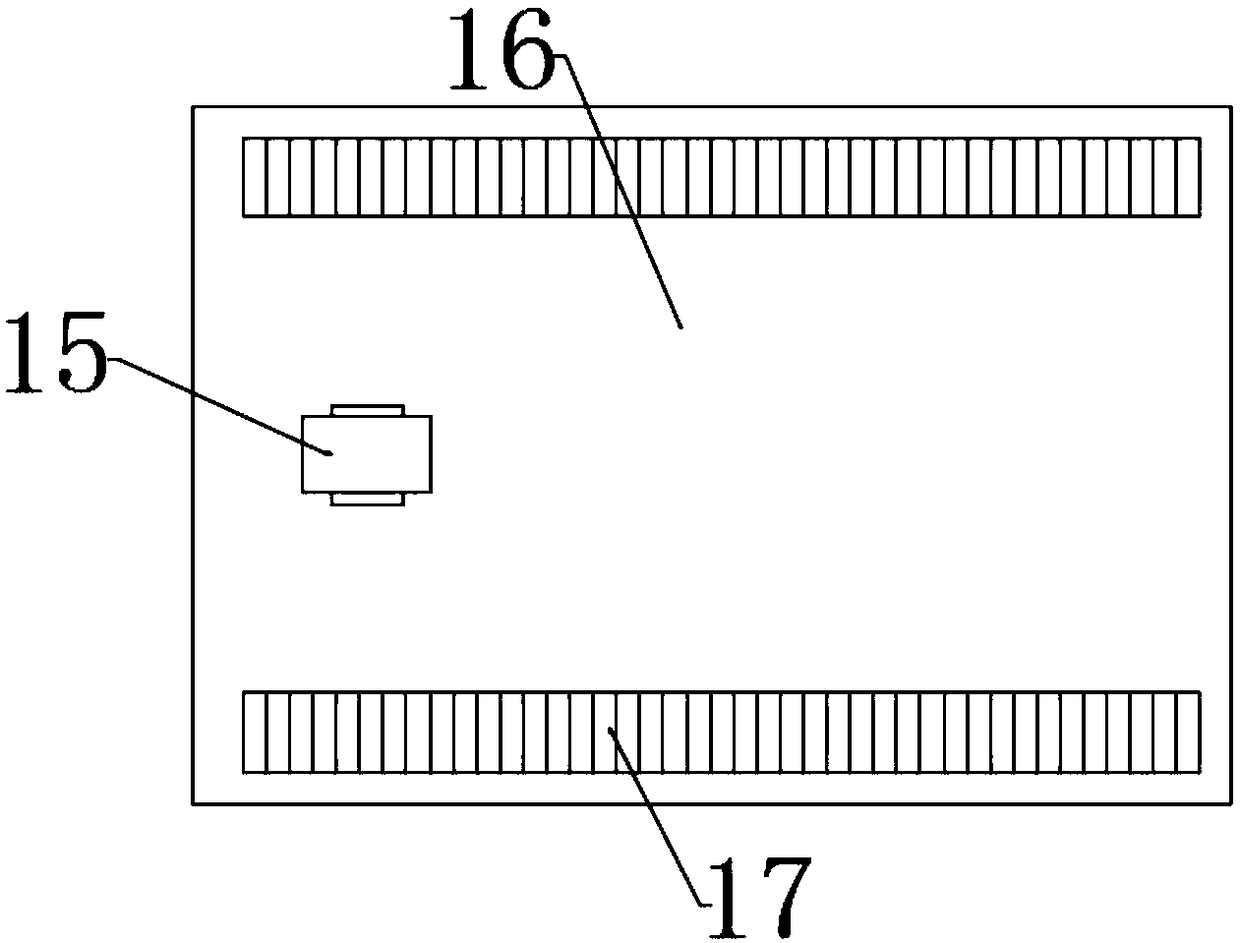

[0022] see Figure 1~3 , in an embodiment of the present invention, an electronic chip anti-corrosion coating printing device, including a device body 1, a crankshaft 3, a spray box 6, a brush roller 11, a workbench 16 and a gear 18; the upper left side of the device body 1 is set There is a drive motor 2, the drive motor 2 is fixedly connected to the motor base, the motor base is fixedly connected to the vertical support plate by bolts, the vertical support plate is fixedly connected to the device body 1, and the lower part of the drive motor 2 is connected to the crankshaft 3 in rotation, and the crankshaft 3 passes through the device The upper edge of the body 1 is rotationally connected with the bearing, the driving motor 2 is connected to the power supply and the switch by wires, and the switch is pressed to make the driving motor 2 energized to drive the crankshaft 3 to rotate; the upper part of the device body 1 is fixedly connected with the spray box 6 and the crankshaf...

Embodiment 2

[0025] In order to make the technical solution of the present application more complete and detailed, some supplementary explanations are made on the basis of the above-mentioned embodiment 1, so that the disclosure of the technical means adopted in the present application is more sufficient. Specifically, the technical characteristics of the added part are , the top left end of the workbench 16 is fixedly connected to the cylinder 22, the inside of the cylinder 22 is sealed and slidably connected to the telescopic rod 23, the two sides of the lower end of the device body 1 are respectively fixedly connected to the legs 21, and the upper right end of the workbench 16 is provided with a raised bump. The chips to be processed are placed on the workbench 16 and clamped by the bumps cooperating with the telescopic rods 23 , so as to achieve the functions of stabilization and clamping.

[0026] The working principle of the present invention is: press the switch to make the drive mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com