Member surface coating mortar and use method thereof

A surface layer and coating technology, which is applied in the construction of buildings, construction, and the processing of building materials, etc., can solve the problems that the surface layer is prone to cracks and cannot be used with adhesive-type alkali-resistant mesh cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

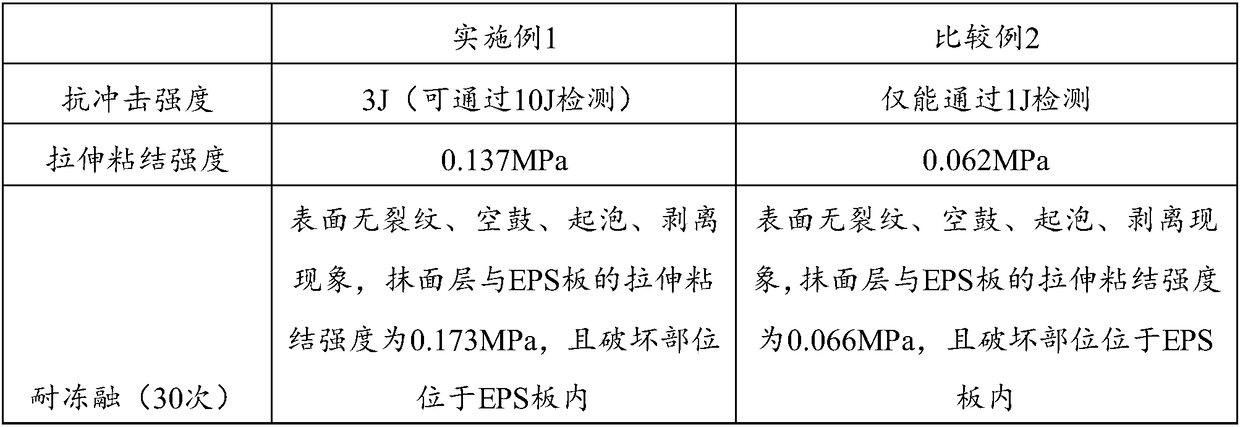

Examples

Embodiment 1

[0047] Each kilogram of liquid material includes: 700 grams of emulsion, 293 grams of water, 6 grams of hydroxyethyl cellulose, and 1 gram of preservative.

[0048] Each kilogram of powder includes: 300 grams of 42.5 grade ordinary Portland cement, 300 grams of coarse sand, 389 grams of fine sand, 5 grams of hydroxypropyl methylcellulose, and 6 grams of lignin fiber.

[0049] The powder and liquid materials are stirred and dispersed evenly for later use. When in use, the ratio of 1:1 (mass) is mixed evenly and then introduced into the spray gun for spraying construction. The number of constructions is 3 times.

Embodiment 2

[0051] Each kilogram of liquid material includes: 600 grams of emulsion, 393 grams of water, 6 grams of hydroxyethyl cellulose, and 1 gram of preservative.

[0052] Each kilogram of powder includes: 300 grams of 42.5 grade ordinary Portland cement, 300 grams of coarse sand, 390 grams of fine sand, 4 grams of hydroxypropyl methylcellulose, and 6 grams of lignin fiber.

[0053] The powder and liquid materials are stirred and dispersed evenly for later use. When in use, the ratio of 1:1 (mass) is mixed evenly and then introduced into the spray gun for spraying construction. The construction times are 5 times.

Embodiment 3

[0055] Each kilogram of liquid material includes: 500 grams of emulsion, 495 grams of water, and 5 grams of hydroxyethyl cellulose.

[0056] Each kilogram of powder includes: 350 grams of 42.5 grade ordinary Portland cement, 300 grams of coarse sand, 340 grams of fine sand, 4 grams of hydroxypropyl methylcellulose, and 6 grams of lignin fiber.

[0057] The powder and liquid materials are stirred and dispersed evenly for later use. When in use, the ratio of 1:0.8 (mass) is mixed evenly and then introduced into the spray gun for spraying construction. The number of times of construction is 3-5 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com