B1 grade flame-retardant rigid polyurethane foam thermal insulation board and preparation method and application thereof

The technology of rigid polyurethane and thermal insulation board is applied in the field of rigid polyurethane foam thermal insulation board, B1 flame retardant rigid polyurethane foam thermal insulation board and its preparation field, which can solve the problems of dispersibility and compatibility of expandable graphite, which have not yet been seen. Polyurethane rigid foam has problems such as failure of flame retardant performance, easy to cause suffocation or even death, etc., to achieve the effect of not easy precipitation, good flame retardant effect, and enhanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The embodiment of the present invention provides a method for preparing a flame-retardant rigid polyurethane foam insulation board, the specific process is as follows:

[0046] S1. Weigh the following raw materials respectively and add them to the mixing tank:

[0047] Polyether polyol: DD4110 50 parts,

[0048] Polyester polyol: 3152 50 parts,

[0049] Turn on the stirring and control the stirring speed to 40-60rpm;

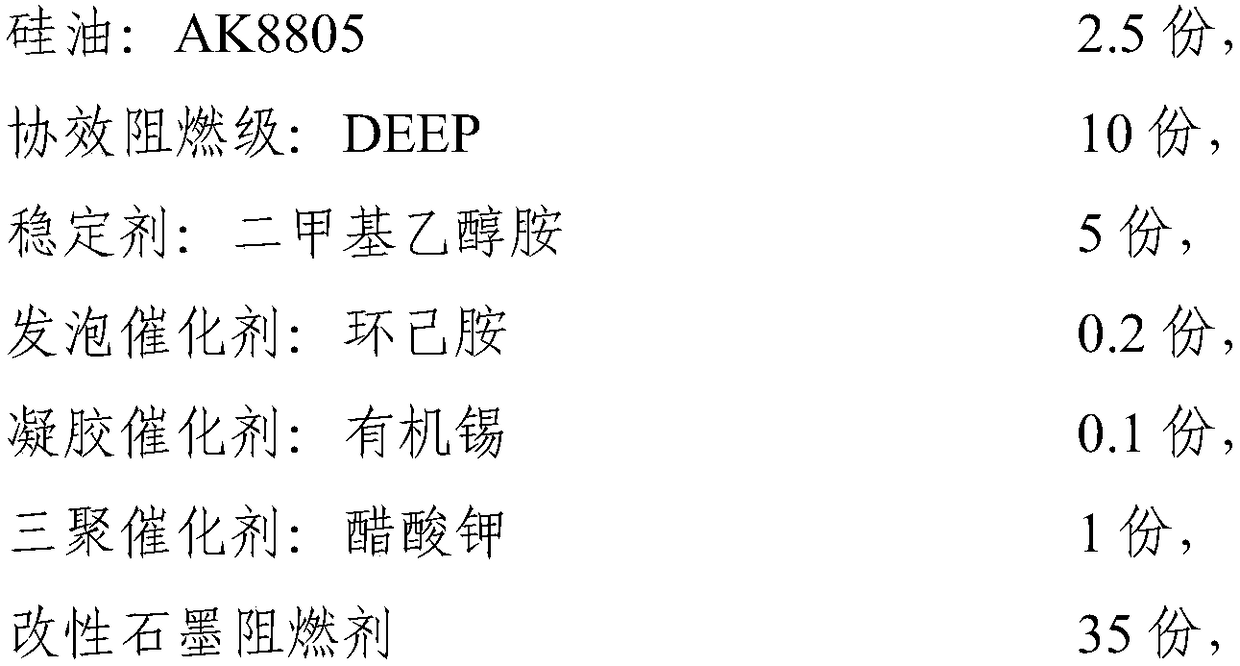

[0050] S2, then weigh the following raw materials respectively, and add them in the mixing tank in step S1 in turn:

[0051]

[0052] Adjust the stirring speed to 60-80rpm, mix for 15-20 minutes, and obtain the polyurethane composite material;

[0053] S3. Inject the polyurethane combination material obtained in step S2 into a stirring tank of the foaming machine, add 10 parts of cyclopentane and 1.4 parts of water, adjust the stirring speed to 50-70rpm, mix well, and inject PM-400 into the foaming machine at the same time In the other mixing tank ...

Embodiment 2

[0056] The embodiment of the present invention provides a method for preparing a flame-retardant rigid polyurethane foam insulation board, the specific process is as follows:

[0057] S1. Weigh the following raw materials respectively and add them to the mixing tank:

[0058] Polyether polyol: SU635 80 parts,

[0059] Polyester polyol: NK175 20 parts,

[0060] Turn on the stirring and control the stirring speed to 40-60rpm;

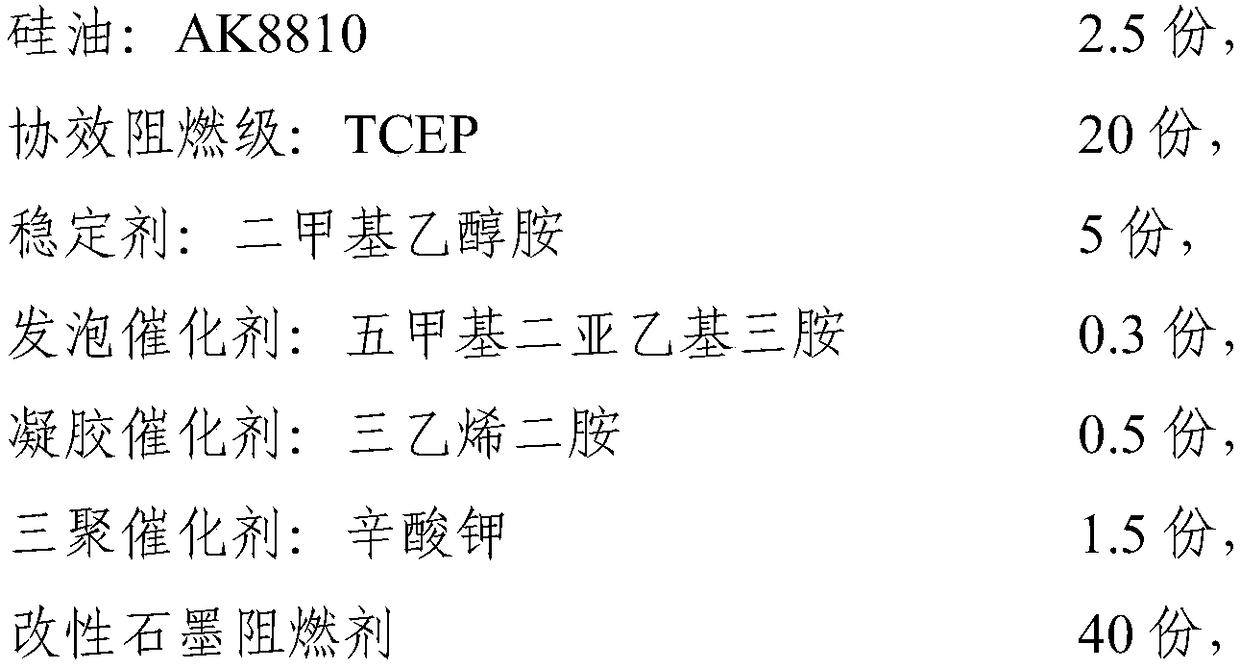

[0061] S2, then weigh the following raw materials respectively, and add them in the mixing tank in step S1 in turn:

[0062]

[0063] Adjust the stirring speed to 60-80rpm, mix for 15-20 minutes, and obtain the polyurethane composite material;

[0064] S3. Inject the polyurethane combination material obtained in step S2 into a stirring tank of the foaming machine, add 12 parts of cyclopentane and 1.2 parts of water, adjust the stirring speed to 50-70rpm, mix well, and inject PM-400 into the foaming machine at the same time In the other mixing tank ...

Embodiment 3

[0067] The embodiment of the present invention provides a method for preparing a flame-retardant rigid polyurethane foam insulation board, the specific process is as follows:

[0068] S1. Weigh the following raw materials respectively and add them to the mixing tank:

[0069] Polyether polyol: SU635 65 parts,

[0070] Polyester polyol: 3152 35 parts,

[0071] Turn on the stirring and control the stirring speed to 40-60rpm;

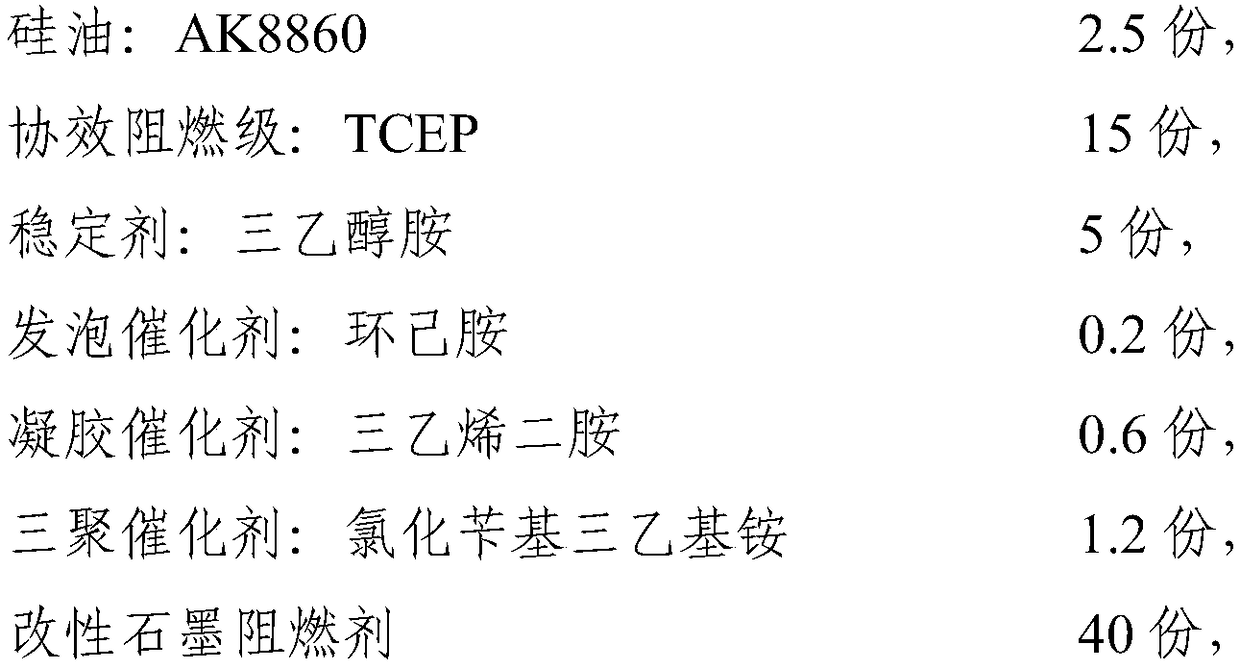

[0072] S2, then weigh the following raw materials respectively, and add them in the mixing tank in step S1 in turn:

[0073]

[0074] Adjust the stirring speed to 60-80rpm, mix for 15-20 minutes, and obtain the polyurethane composite material;

[0075] S3. Inject the polyurethane combination material obtained in step S2 into a stirring tank of the foaming machine, add 13 parts of cyclopentane and 1.1 parts of water, adjust the stirring speed to 50-70rpm, mix well, and inject PM-400 into the foaming machine at the same time In the other mixing tank o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gel time | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com