Heat treatment method for middle ring of synchronizer and middle ring structure

A heat treatment method and intermediate ring technology, which are applied in heat treatment furnaces, heat treatment equipment, couplings, etc., can solve the problems of wear of synchronizer intermediate rings and synchronizing rings, unstable oil volume, and prone to broken claws. Wear, improved stability, good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

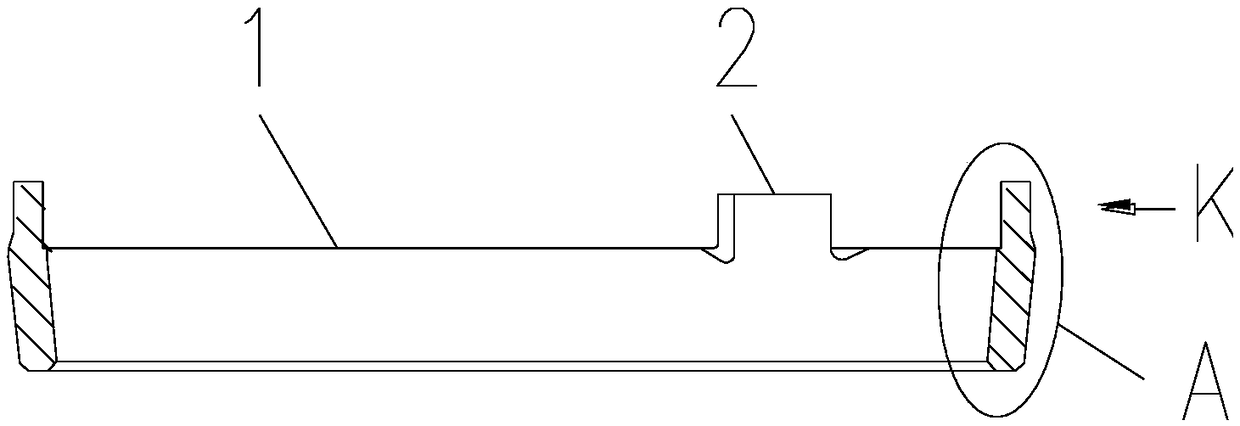

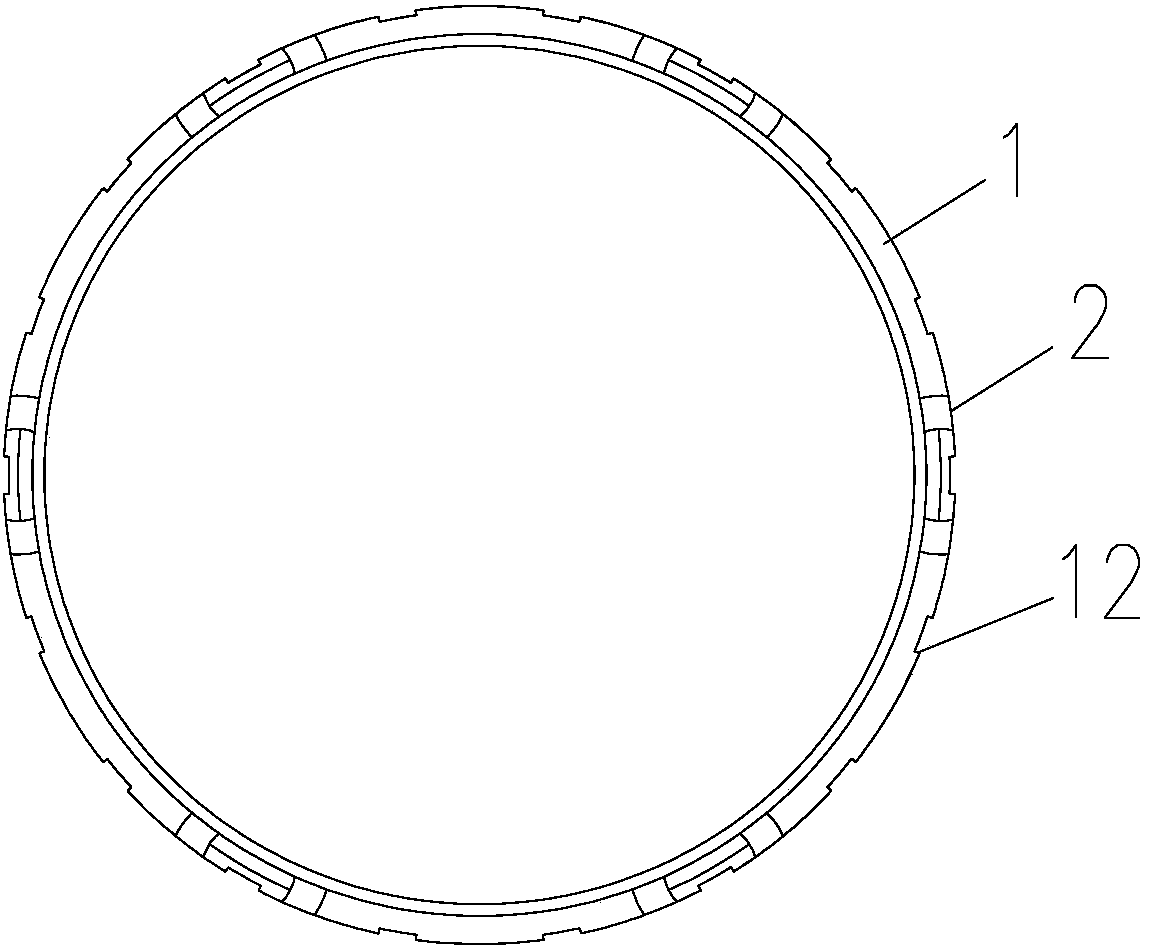

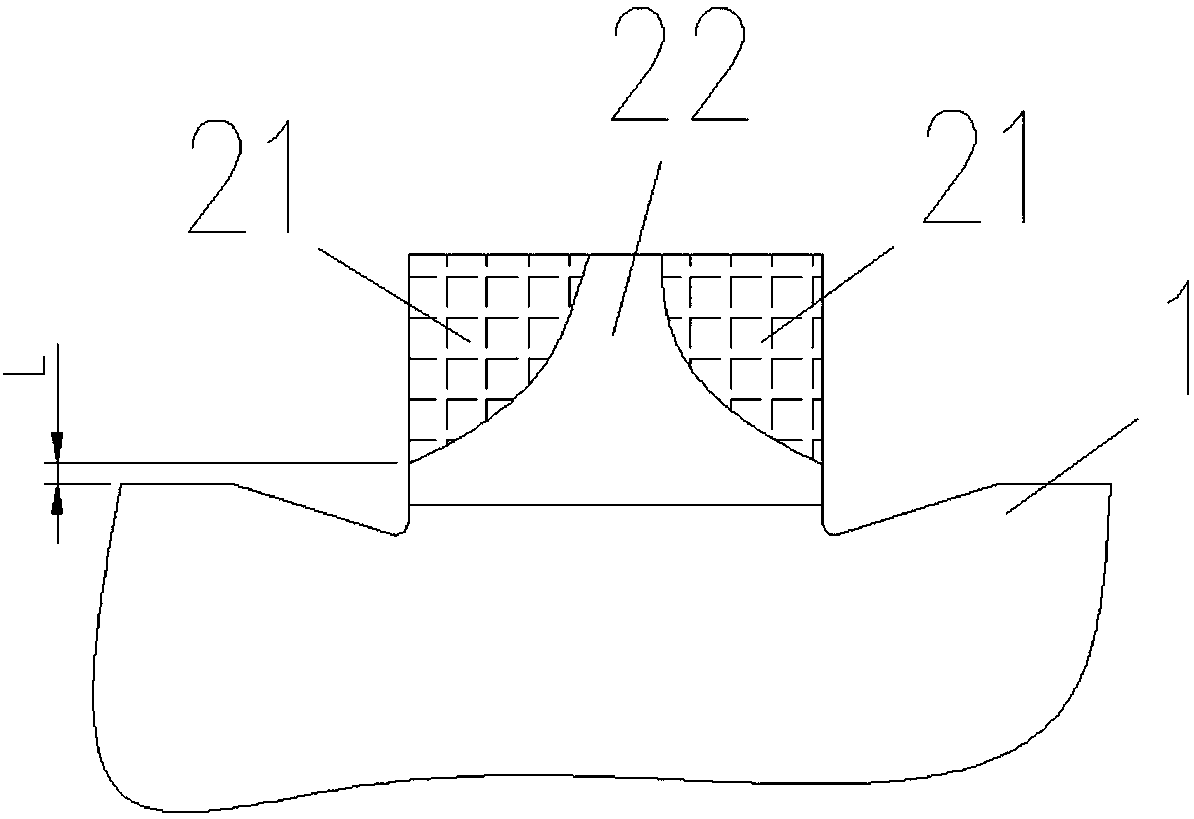

[0027] Such as Figure 1-Figure 4 Shown is a specific embodiment of a heat treatment method for a synchronizer intermediate ring of the present invention. The intermediate ring includes a cone ring body 1 and several prongs 2 arranged on the cone ring body 1. The heat treatment process of the intermediate ring includes the following steps:

[0028] S1, subjecting the intermediate ring to quenching and tempering treatment; preferably, the hardness of the intermediate ring after quenching and tempering satisfies 240-280 HV.

[0029] S2, according to the contact size of the claw 2 and other parts when the claw 2 is working, divide the claw 2 into an edge strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com