Anti-static coating liquid

A coating liquid, anti-static technology, applied in coatings, paper coatings, textiles and papermaking, etc., can solve the problems of stability affecting anti-static ability, anti-static agents affecting anti-static effect, etc., to achieve novel and unique products, The effect of not easy to fall off and strong antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of antistatic coating liquid, comprises the raw material of following weight ratio:

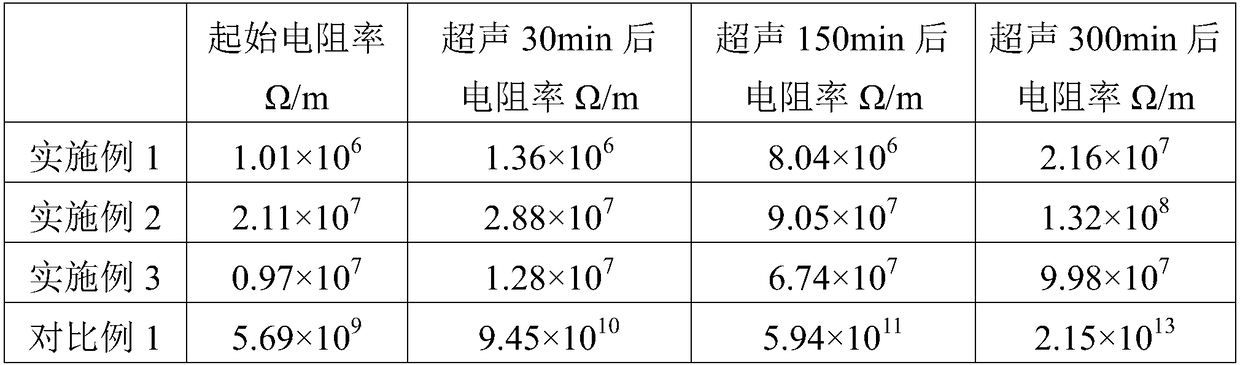

[0018] The model of Shandong Baite New Material Co., Ltd. is adopted to be 18% of neutral silica sol N2510, 24% of sodium polystyrene sulfonate, 0.8% of betaine, and the rest are water. SiO in the neutral silica sol 2 The concentration is 25%, and SiO in neutral silica sol 2 The average particle diameter of the sodium polystyrene sulfonate is 12nm, the average molecular weight of the polystyrene sodium sulfonate is 60,000, and the sulfonation degree is 75%. The antistatic coating liquid of the present invention is prepared after mixing the above raw materials. The antistatic coating solution of the present invention is evenly coated on the back side of RC photographic paper, and the coating amount is 0.3g / m 2 . The surface resistivity of the coated RC paper was measured to be 1.01×10 6 Ω / m.

Embodiment 2

[0020] A kind of antistatic coating liquid, comprises the raw material of following weight ratio:

[0021] The model of Shandong Baite New Material Co., Ltd. is adopted to be 20% of neutral silica sol N2510, 20% of sodium polystyrene sulfonate, 1% of betaine, and the rest are water. SiO in the neutral silica sol 2 The concentration is 25%, and SiO in neutral silica sol 2 The average particle diameter of the polystyrene sodium sulfonate is 10nm, the average molecular weight of the polystyrene sodium sulfonate is 80,000, and the sulfonation degree is 72%. The antistatic coating liquid of the present invention is prepared after mixing the above raw materials. The antistatic coating solution of the present invention is evenly coated on the back side of RC photographic paper, and the coating amount is 0.25g / m 2 . The surface resistivity of the coated RC paper was measured to be 2.11×10 7 Ω / m.

Embodiment 3

[0023] A kind of antistatic coating liquid, comprises the raw material of following weight ratio:

[0024] The model of Shandong Baite New Material Co., Ltd. is adopted to be 10% of neutral silica sol N2510, 30% of sodium polystyrene sulfonate, 0.1% of betaine, and the rest are water. In the neutral silica sol, SiO 2 The concentration is 25%, and SiO in neutral silica sol 2 The average particle diameter of the polystyrene sodium sulfonate is 15nm, the average molecular weight of the polystyrene sodium sulfonate is 70,000, and the sulfonation degree is 80%. The antistatic coating liquid of the present invention is prepared after mixing the above raw materials. The antistatic coating solution of the present invention is evenly coated on the back side of RC photographic paper, and the coating amount is 0.28g / m 2 . The surface resistivity of the coated RC paper was measured to be 0.97×10 7 Ω / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com