Charcoal-roasted yogurt stick and preparation method thereof

A yogurt stick and charcoal burning technology, which is applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problem that solid yogurt cannot retain a solid form and taste smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 A kind of preparation method of charcoal roasted yoghurt bar

[0040] The preparation method of charcoal-burned yoghurt bar in the present embodiment comprises the following steps carried out successively:

[0041] 1) Preparation of charcoal yogurt

[0042] Take 44.30kg of raw milk, 2.53kg of L-arabinose and 3.16kg of fine granulated sugar (with a particle size of 50 mesh) and mix well, heat to 55°C, then homogenize at 18MPa, and then heat to 100°C for Maillard React for 2.0 hours (stirring every 30 minutes, 30s each time), sterilize at 90°C for 300s, cool down to 43°C, and then add 63.3g of starter (starter is 31.65g of Streptococcus thermophilus powder and 31.65g of German Lactobacillus subsp. bulgaricus powder mixed), maintained at 43 ° C for 4 hours to produce a sufficient amount of active lactic acid bacteria and amino acids and other nutrients, and made charcoal-fired yoghurt, marked as M1, in which Streptococcus thermophilus and German The total nu...

Embodiment 2~6

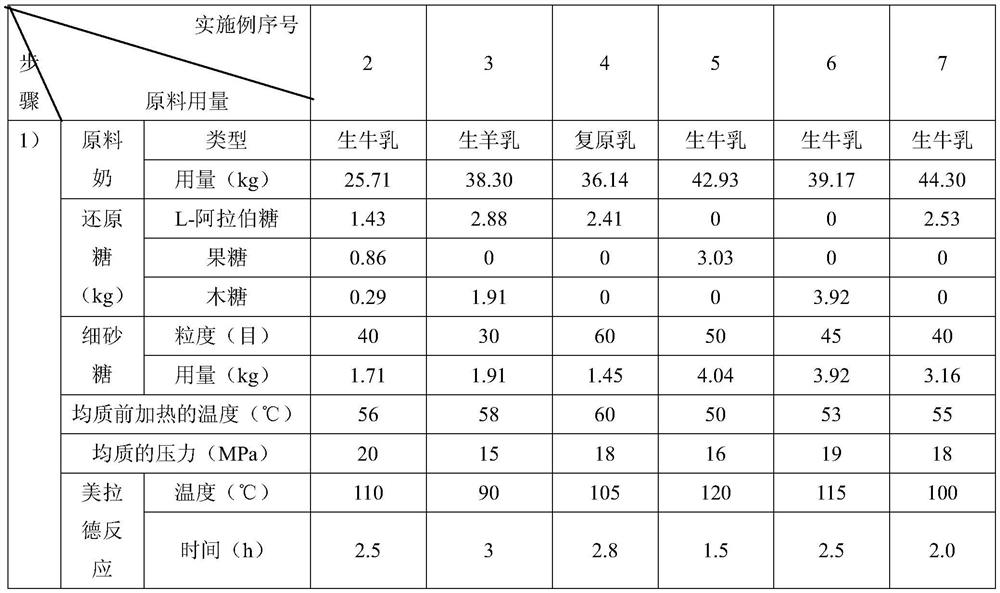

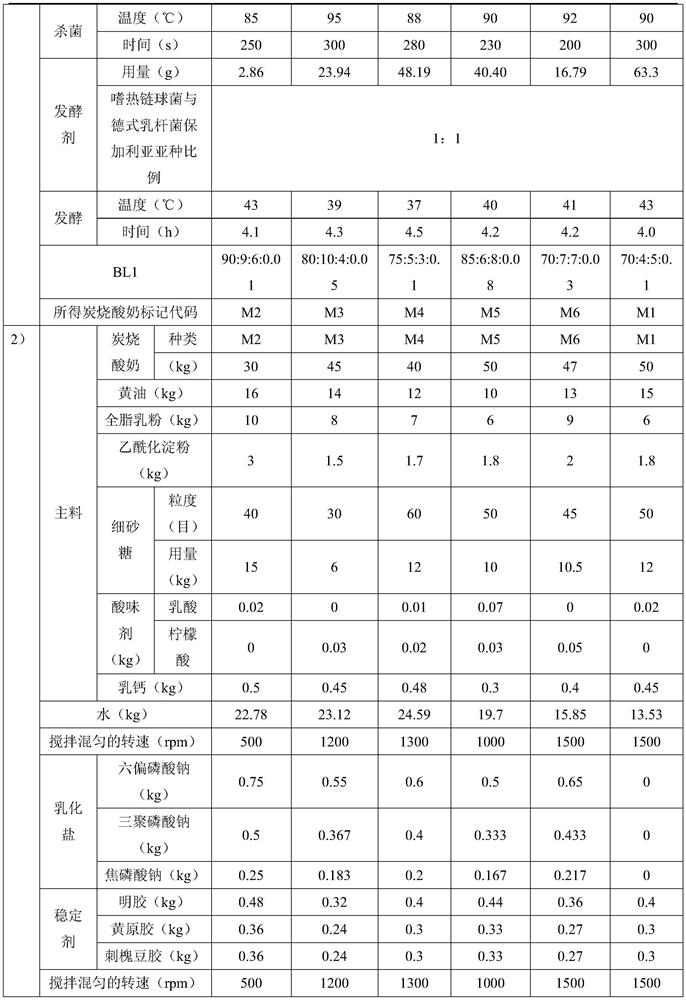

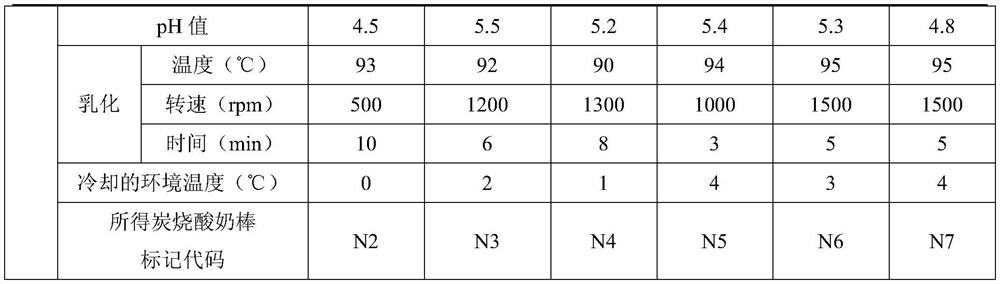

[0047] The preparation method of embodiment 2~6 charcoal-fired yoghurt bar

[0048] Examples 2 to 6 are respectively a method for preparing charcoal-fired yoghurt sticks. Their steps are basically the same as those in Example 1, except that the amount of raw materials used and the process parameters in the preparation process are different. See Table 1 for details:

[0049] Table 1 List of raw material consumption and parameters in charcoal-burned yogurt sticks

[0050]

[0051]

[0052]

[0053] The content of the other parts of Examples 2-6 is the same as that of Example 1.

Embodiment 7

[0055] Example 7 Charcoal-burned yoghurt bar sensory evaluation

[0056] 100 ordinary consumers were recruited to conduct sensory evaluation on charcoal yogurt sticks N1~N6 and charcoal yogurt product D7 by anonymous scoring method. Comprehensive evaluation of characteristics such as charcoal flavor), overall liking and whether it can be hand-held, a total of 6 indicators are evaluated. The lowest score is 1 point, and the full score is 10 points. The higher the score, the better the effect. After the tasting, the sensory evaluation results of 100 ordinary consumers were statistically analyzed, and the average scores are shown in the table below:

[0057] Table 2 List of sensory evaluation results of charcoal-fired yogurt sticks N1-N6

[0058] Test article code organizational status color odor Taste overall liking Whether it can be held N1 8.5 8.1 8.3 8.5 8.3 yes N2 8.0 7.8 7.5 7.3 7.8 yes N3 7.3 8.0 7.2 7.1 7.0 yes N4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com