Automatic gearbox oil cooling heat dissipation electromagnetic valve and heat dissipation method

A technology of automatic transmission oil and solenoid valve, applied in valve details, valve device, valve housing structure, etc., can solve problems such as short service life, poor heat dissipation efficiency, coil damage, etc., to avoid jamming, improve working life, The effect of avoiding overheating phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

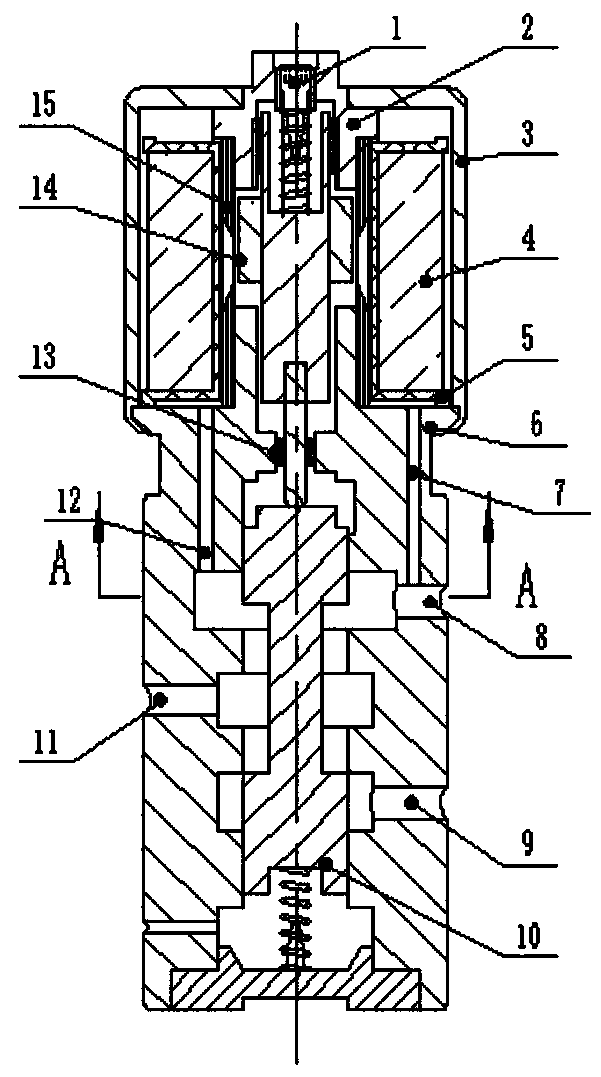

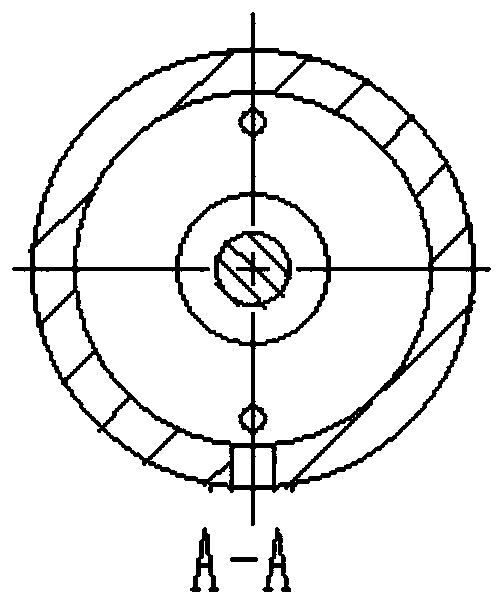

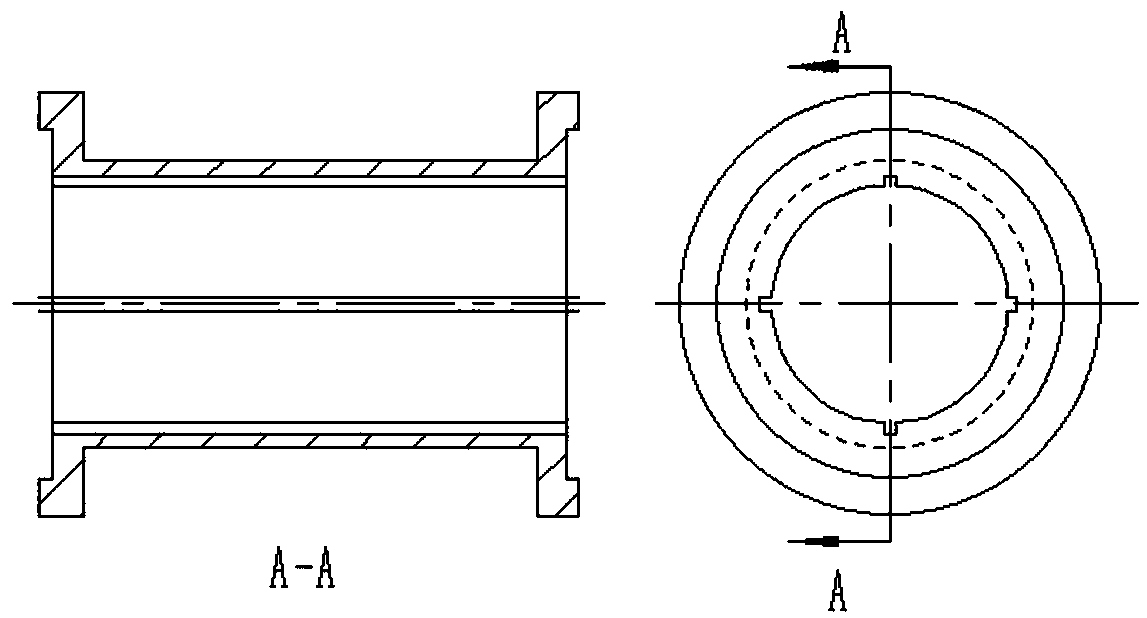

[0032] A specific embodiment of the present invention discloses an oil-cooling and heat-dissipating solenoid valve for an automatic transmission. The solenoid valve includes: an adjusting nut 1, a rear yoke 2, a casing 3, an oil discharge port 8, an oil connection port 9, an output port 11, Sealing ring 13 , armature 14 , sleeve 15 , return spring and end cover, electromagnetic coil 4 , coil frame 5 , valve body 6 and valve core assembly 10 . Two connecting holes are designed between the inner space of the electromagnet of the solenoid valve and the oil discharge port 8 of the valve body 6 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com