Positive electrode material and lithium ion battery

一种正极材料、基体材料的技术,应用在电池领域,能够解决恶化电芯整体性能表现、克容量和循环性能衰减、恶化电芯存储性能等问题,达到避免不可逆转变、改善循环性能、结构稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

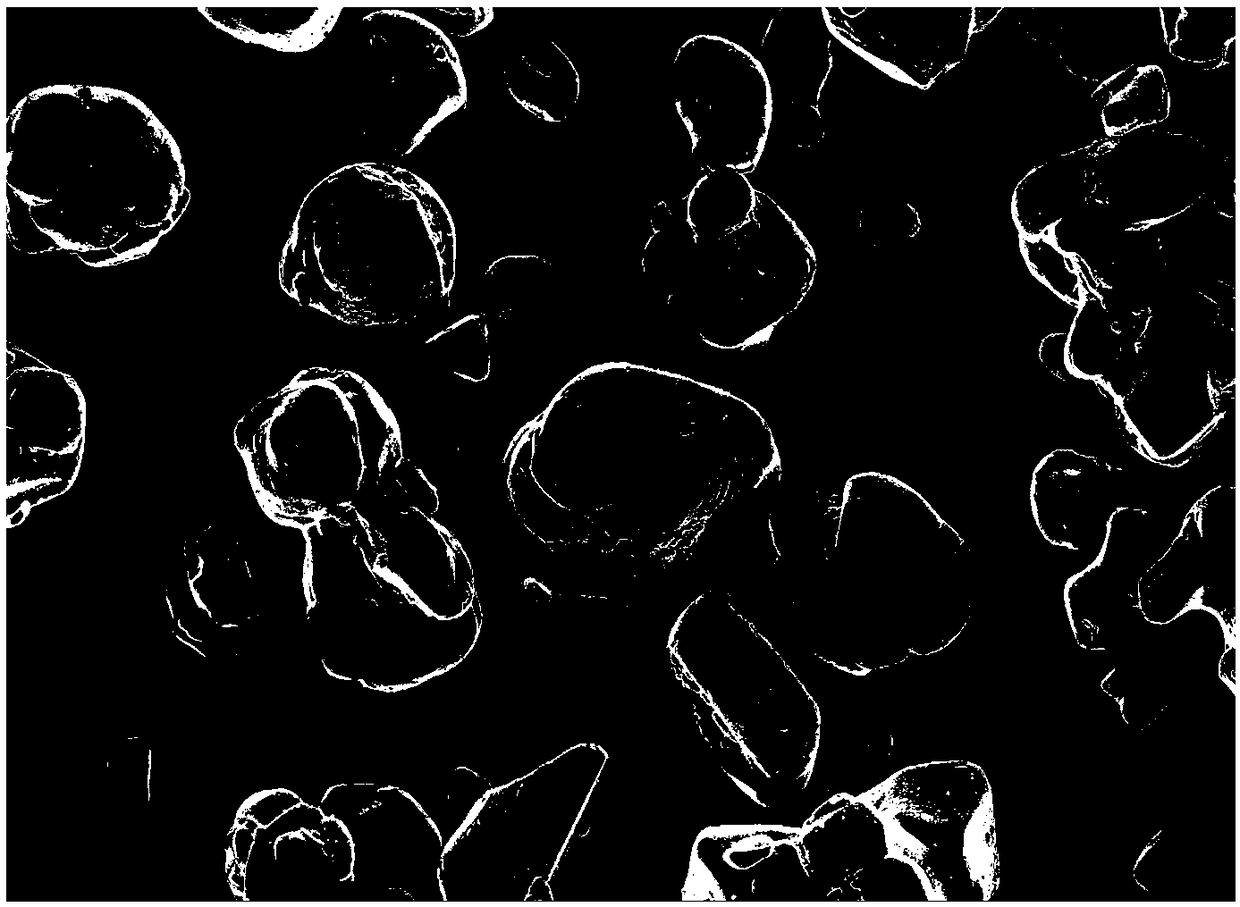

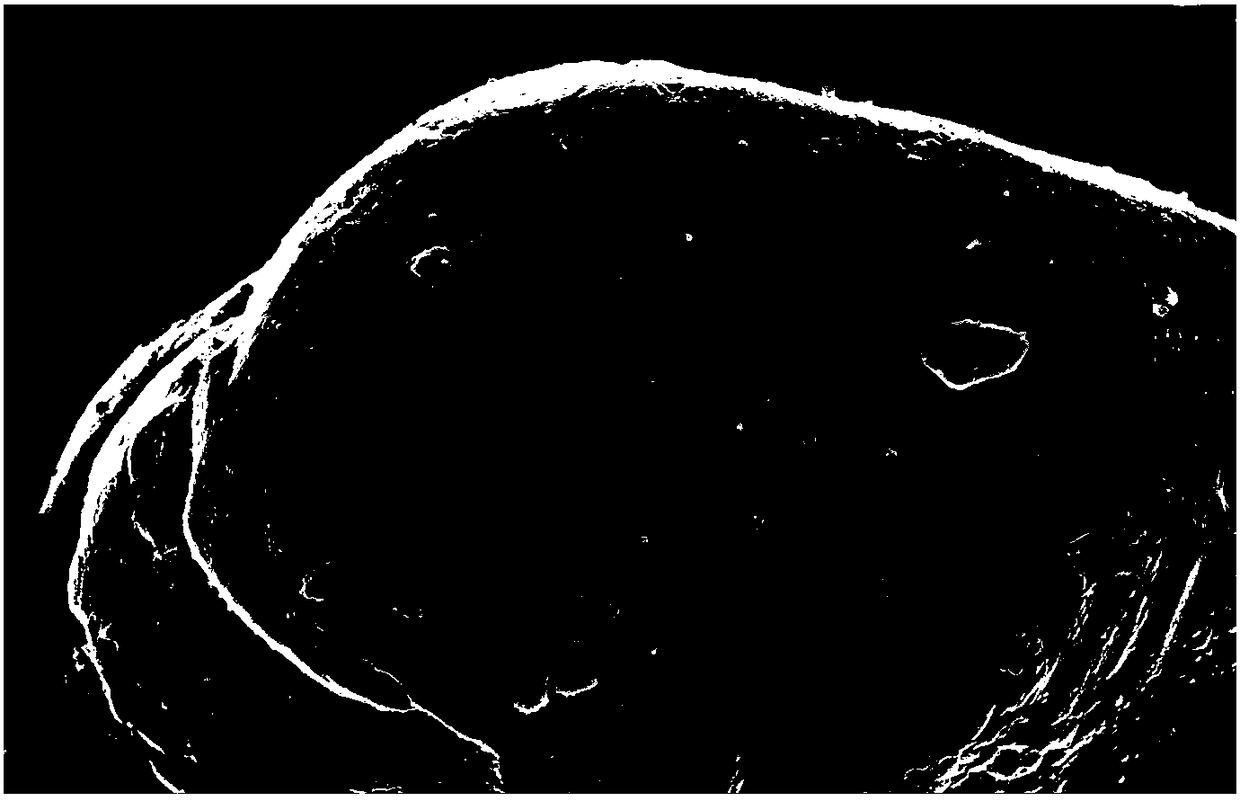

Image

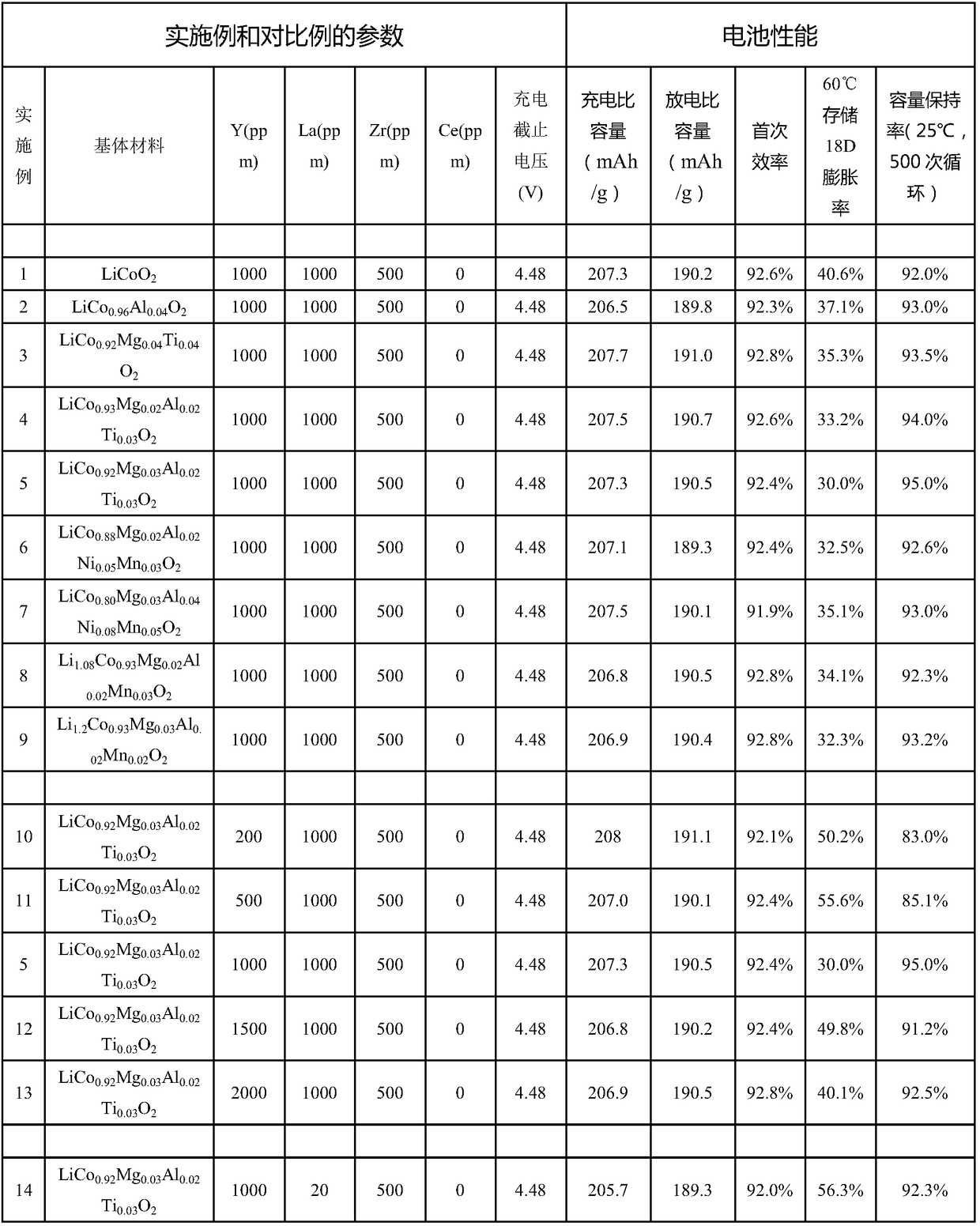

Examples

Embodiment 1

[0034] Weigh 5Kg of LiCO 2 sample, as the base material. Calculate and weigh La according to the corresponding content 2 o 3 , Y 2 o 3 , ZrO 2 The amount, as a coating material. Y 2 o 3 The content of Y in the coated positive electrode material is 1000ppm, La 2 o 3 The content of La in the coated positive electrode material is 1000ppm, ZrO 2 The content of Zr in the coated positive electrode material is 500ppm. Combine cladding material with LiCoO 2 For blending and coating, use an inclined mixer to mix and stir for 8 hours; put the uniformly mixed material into a sintering furnace for sintering, raise the temperature to 800°C at a rate of 10°C / min and keep it for 8 hours, and then naturally cool to room temperature; crush and sieve the sintered sample to obtain a coated positive electrode material with an average particle size of about 5 μm. A full battery was prepared on the obtained coated positive electrode material, and various performances of the battery wer...

Embodiment 2

[0036] Consistent with the preparation method of Example 1, the difference is that the matrix material used in Example 2 is LiCo 0.96 al 0.04 o 2 , the cladding material used and the content of metal elements in the cladding material are as follows: Y 2 o 3 The Y content in is 1000ppm, La 2 o 3 The content of La in ZrO is 1000ppm, ZrO 2 The content of Zr in is 500ppm.

Embodiment 3

[0038] Consistent with the preparation method of Example 1, the difference is that the matrix material used in Example 3 is LiCo 0.92 Mg 0.04 Ti 0.04 o 2 , the cladding material used and the content of metal elements in the cladding material are as follows: Y 2 o 3 The Y content in is 1000ppm, La 2 o 3 The content of La in ZrO is 1000ppm, ZrO 2 The content of Zr in is 500ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com