Electric drives and electric equipment

An electric drive and electric equipment technology, applied in the control of electromechanical transmission, motor generator control, control of electromechanical brakes, etc., can solve the problem of the increase in heat generation and temperature rise of the power switch tube, affecting the reliability and safety of the electric drive device. and other problems to achieve the effect of reducing temperature rise, improving reliability and safety, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, achieved objects and effects of the present invention easy to understand and understand, the specific embodiments of the present invention are described below with reference to the accompanying drawings.

[0032] The electric drive device 10 is arranged in electric equipment such as electric tools, electric vehicles, electric boats, high-speed passenger elevators, variable frequency central air conditioners, electrified trains, electric chariots, electric warships, electric aircraft, and electric-driven aircraft carriers, etc. Drive electric equipment.

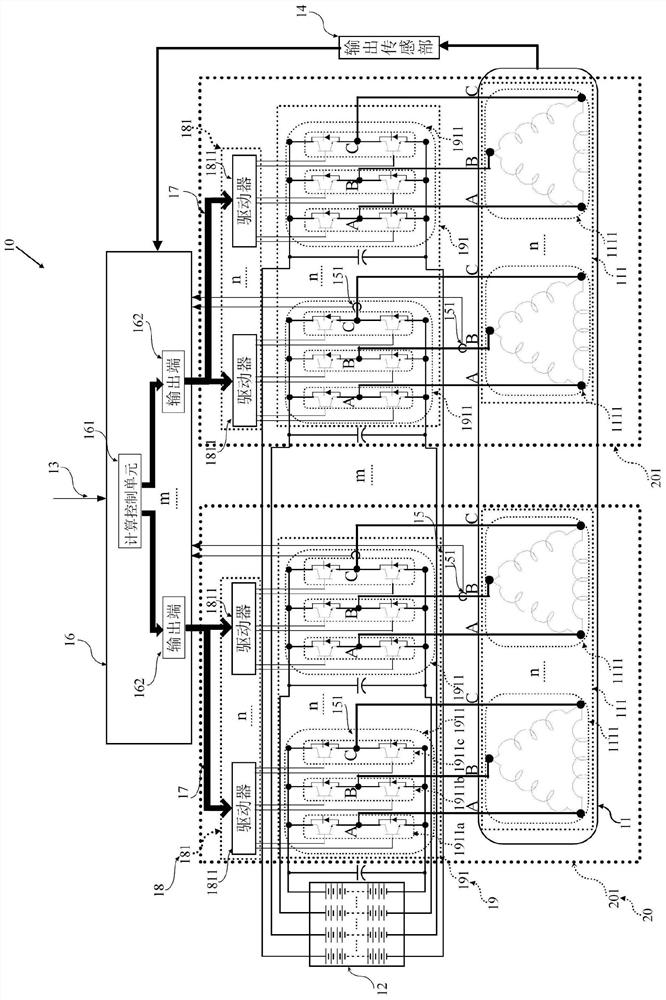

[0033] figure 1 It is a schematic diagram of the circuit structure of the electric drive device in this embodiment.

[0034] like figure 1 As shown, the electric drive device 10 includes a polyphase motor 11 , a DC power supply 12 , an output sensing unit 14 , an inner loop sensing unit 15 , a control unit 16 , a driving unit 18 and a power conversion unit 19 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com