Peroxycarboxylic acid disinfectant and preparation method thereof

A technology of peroxycarboxylic acid and disinfectant, applied in the directions of botanical equipment and methods, disinfectants, chemicals for biological control, etc. Excellent effect and enhanced bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

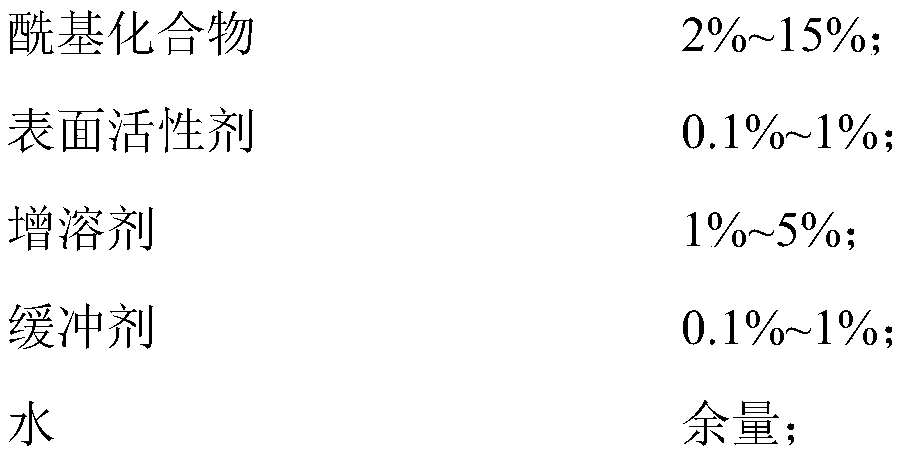

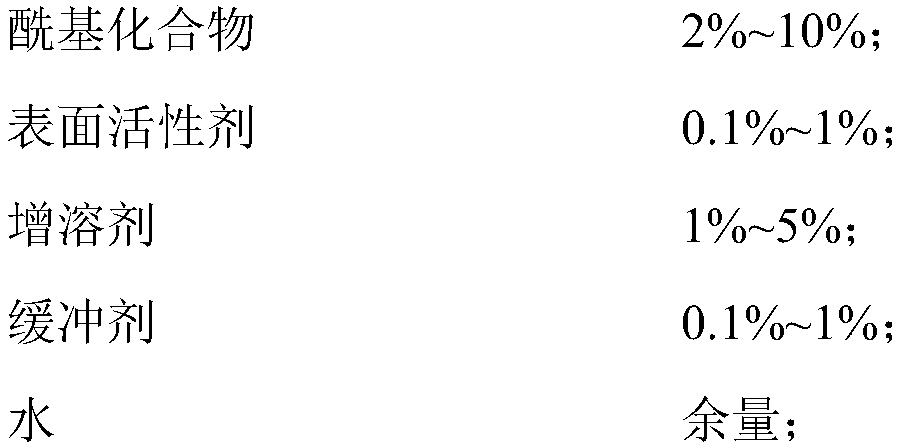

Method used

Image

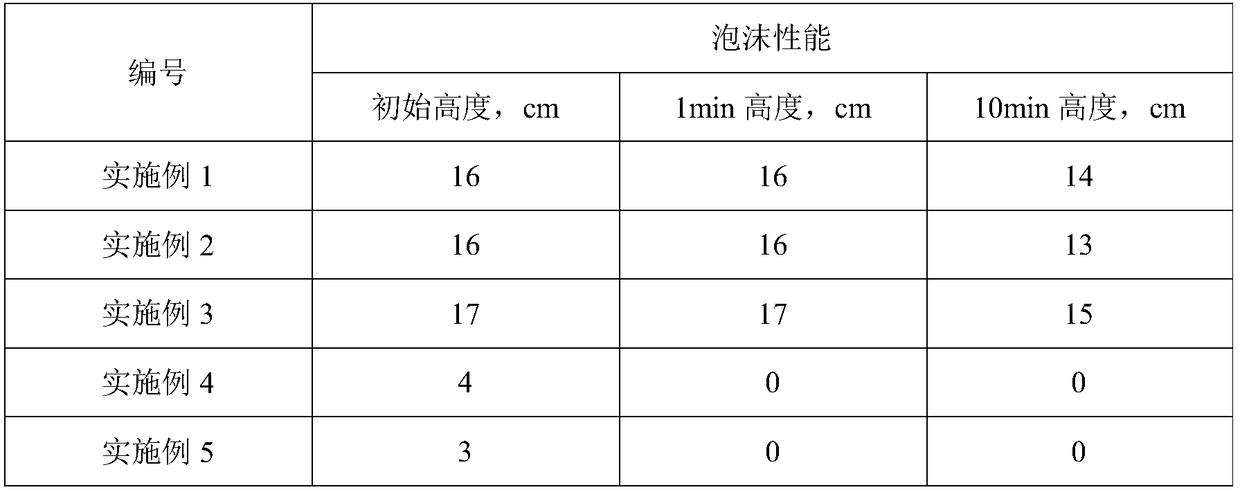

Examples

Embodiment 1

[0050] The raw material composition (parts by mass) of the peroxycarboxylic acid disinfectant A component and the B component of embodiment 1 is as follows respectively:

[0051] Component A: 3 parts of tetraacetylethylenediamine, 2 parts of sodium octanoyloxybenzenesulfonate, 0.5 part of benzalkonium chloride, 0.2 part of Berol 260, 2 parts of ethanol, 0.5 part of citric acid, and 90 parts of water.

[0052] Component B: 4 parts of sodium perborate, 0.2 part of dipicolinic acid, and 95 parts of water.

[0053] When in use, mix 20 parts of component A with 80 parts of component B, and stir for 5 minutes to generate a peroxycarboxylic acid mixture with a pH value of 6.83.

Embodiment 2

[0055] The raw material composition (mass parts) of the peroxycarboxylic acid disinfectant solution A component and B component of embodiment 2 is as follows respectively:

[0056] Component A: 2 parts of acetylsalicylic acid, 3 parts of caprylyl hydroxamic acid, 0.5 part of didecyldimethylammonium chloride, 2660.2 parts of Berol, 2 parts of ethanol, 0.5 part of phthalic acid, and 90 parts of water.

[0057] Component B: 5 parts of hydrogen peroxide, 0.2 part of dipicolinic acid, and 95 parts of water.

[0058] When in use, mix 15 parts of component A with 85 parts of component B, and stir for 5 minutes to generate a peroxycarboxylic acid mixture with a pH value of 6.91.

Embodiment 3

[0060] The raw material composition (parts by mass) of the peroxycarboxylic acid disinfectant solution A component and B component of embodiment 3 is as follows respectively:

[0061] Component A: 3 parts of hydantoin, 2 parts of 2-octanoyloxybenzoic acid, 0.5 parts of dioctyldimethylammonium chloride, 0.2 parts of Berol8400, 2 parts of isopropanol, ethylenediaminetetraacetic acid 0.5 parts of disodium, 90 parts of water.

[0062] Component B: 5 parts of sodium percarbonate, 0.2 parts of hydroxyethylidene diphosphonic acid, and 95 parts of water.

[0063] When in use, mix 25 parts of component A with 75 parts of component B, and stir for 5 minutes to generate a peroxycarboxylic acid mixture with a pH value of 7.31.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com