High-life tundish cover

A tundish and life-span technology, applied in casting melt containers, metal processing equipment, casting equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

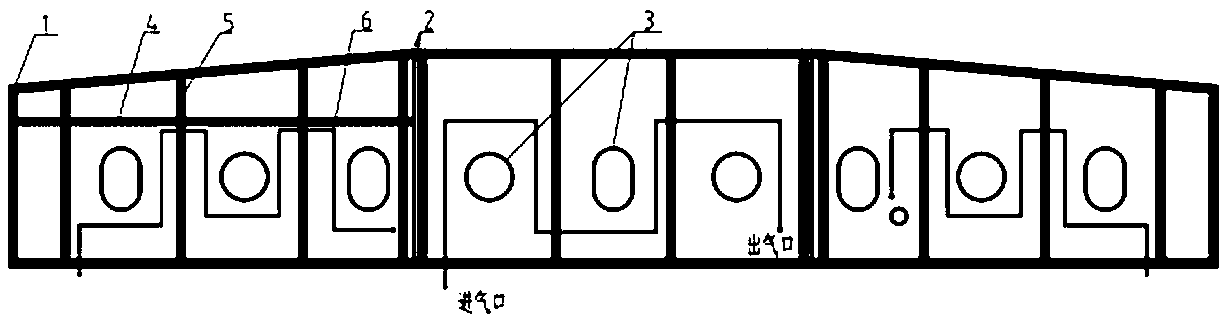

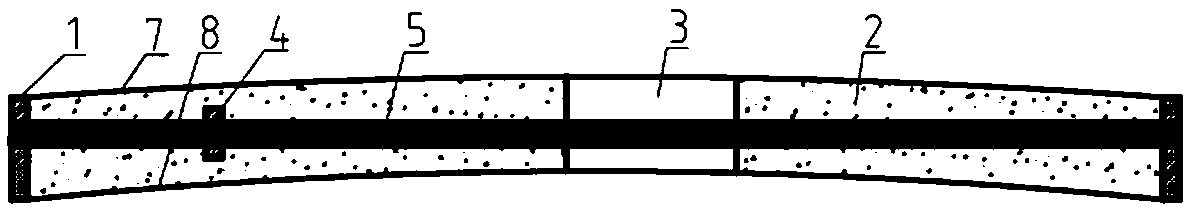

[0021] see figure 1 and figure 2 , a high-life tundish cover, the two sides of the main structure, that is, the upper non-working surface 7 and the lower working surface 8 are designed in the shape of an arch bridge, and the bottom surfaces around are in the same plane. The main structure is a refractory molded body 2, and its interior A skeleton structure is provided, and baking holes and stopper holes 3 are reserved. A protective steel fence 1 is provided on the periphery of the main structure, and the protective steel fence 1 at the splicing seam of the cover is wrapped by refractory castables.

[0022] The skeleton structure contains a circular metal pipe network 5 that is connected, arc-shaped lines interweave, and multi-point connected to the atmosphere. The circular pipe wall thickness in the design is 15-30mm, the inner diameter is not less than 10mm, and the circular pipe is used as the skeleton bridging support ( It is only perpendicular to the length direction of ...

Embodiment 2

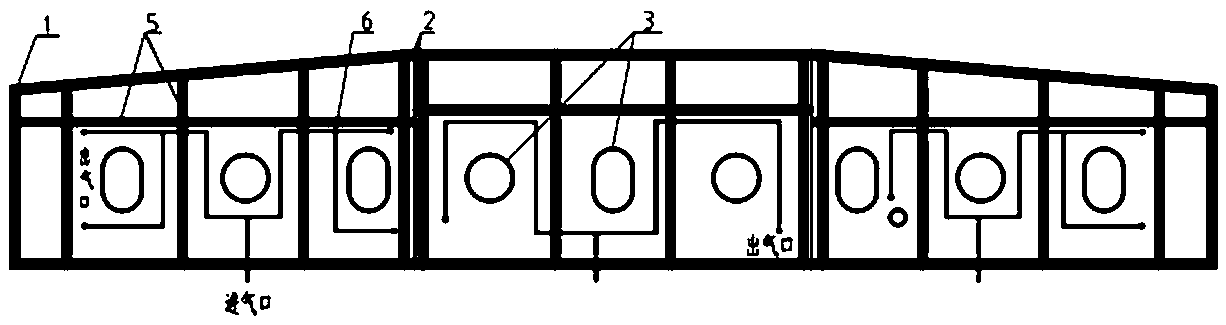

[0024] see image 3 and Figure 4 , a high-life tundish cover, the upper non-working surface 7 of the main structure is a plane, the lower working surface 8 is designed as an arch bridge, and the surrounding bottom surfaces are in the same plane. The main structure is a refractory molded body 2, and there are built-in The skeleton structure is reserved with baking holes and stopper holes 3, and the periphery of the main structure is provided with a protective steel fence 1, and the protective steel fence 1 covering the spliced joints is wrapped by refractory castables.

[0025]The skeleton structure contains a circular metal pipe network 5 that is connected, arc-shaped lines interweave, and multi-point connected to the atmosphere. The circular pipe wall thickness in the design is 15-30mm, the inner diameter is not less than 10mm, and the circular pipe is used as the skeleton bridging support ( Vertical and parallel tundish length direction criss-cross arrangement); the skel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com