Shock excitation broaching device of accommodating cavity dynamic pressurization and shock excitation parameter adjusting method of shock excitation broaching device

A vibration-exciting and dynamic technology, which is applied in broaching devices, fluid pressure actuators, broaching machines, etc., can solve the problems affecting the vibration-exciting performance, the excitation frequency and amplitude cannot be adjusted accurately, and the driving method is cumbersome, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing.

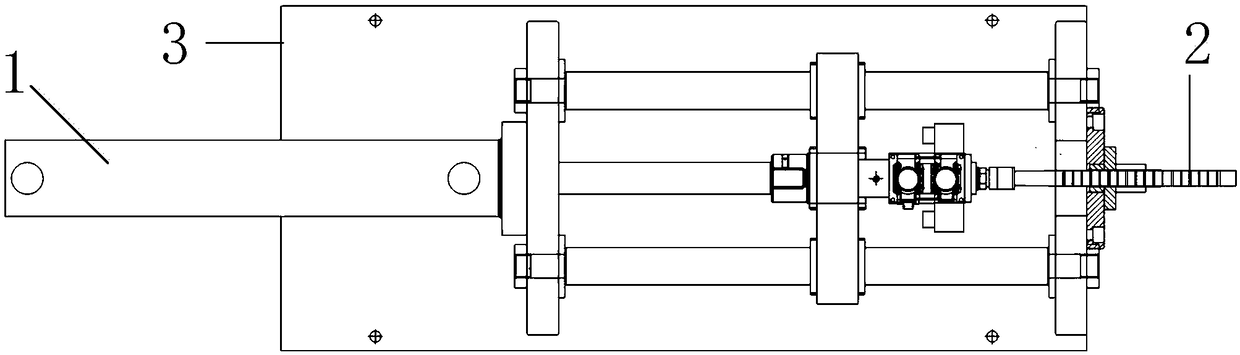

[0050] Such as figure 1 As shown, the vibration broaching device with dynamic pressurization of the cavity includes a broaching main hydraulic cylinder 1, a broach 2, a frame 3, an electro-hydraulic drive part, a signal feedback part and a system state monitoring and control part. The main hydraulic cylinder 1 for broaching is fixed on the frame 3 .

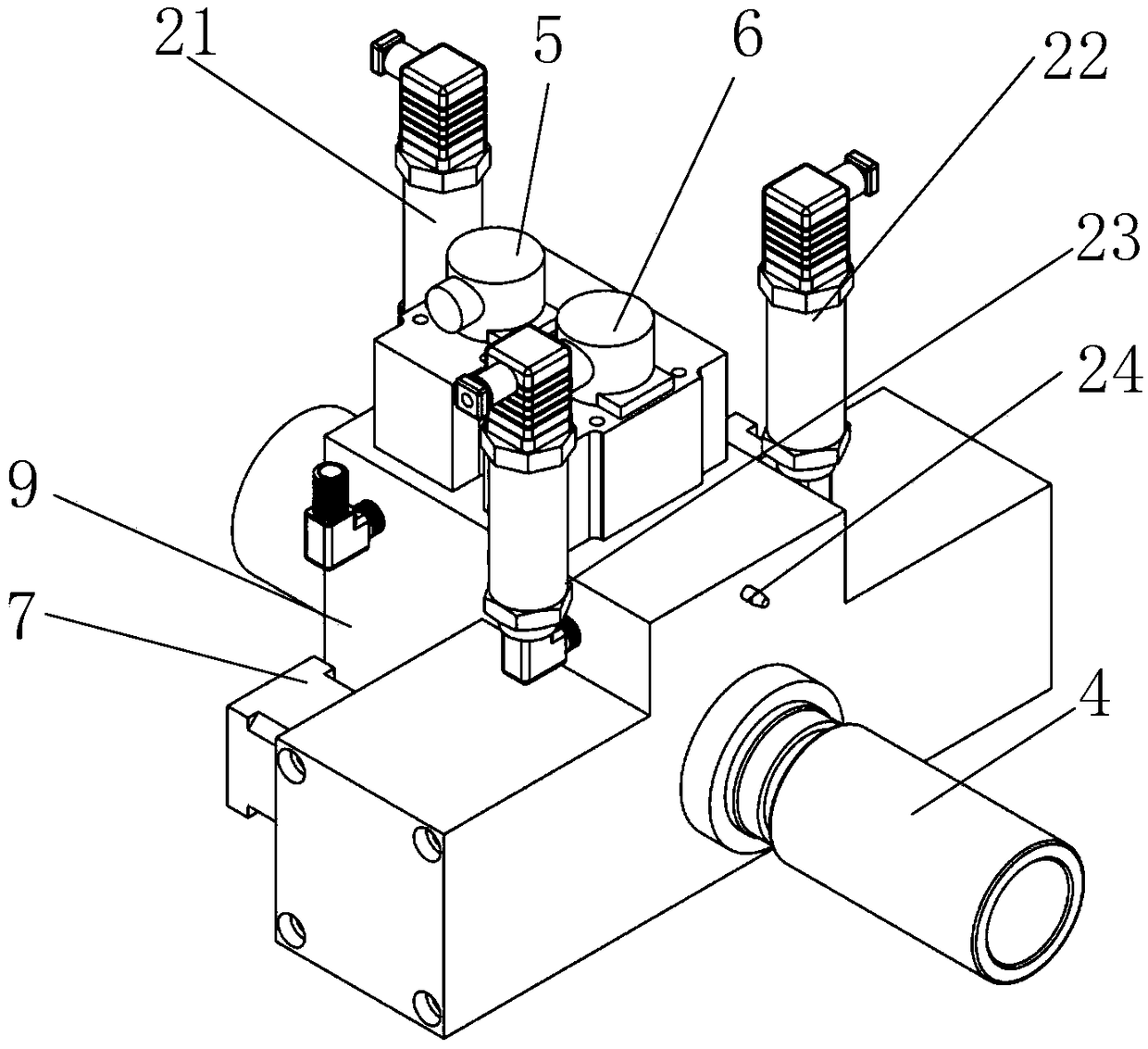

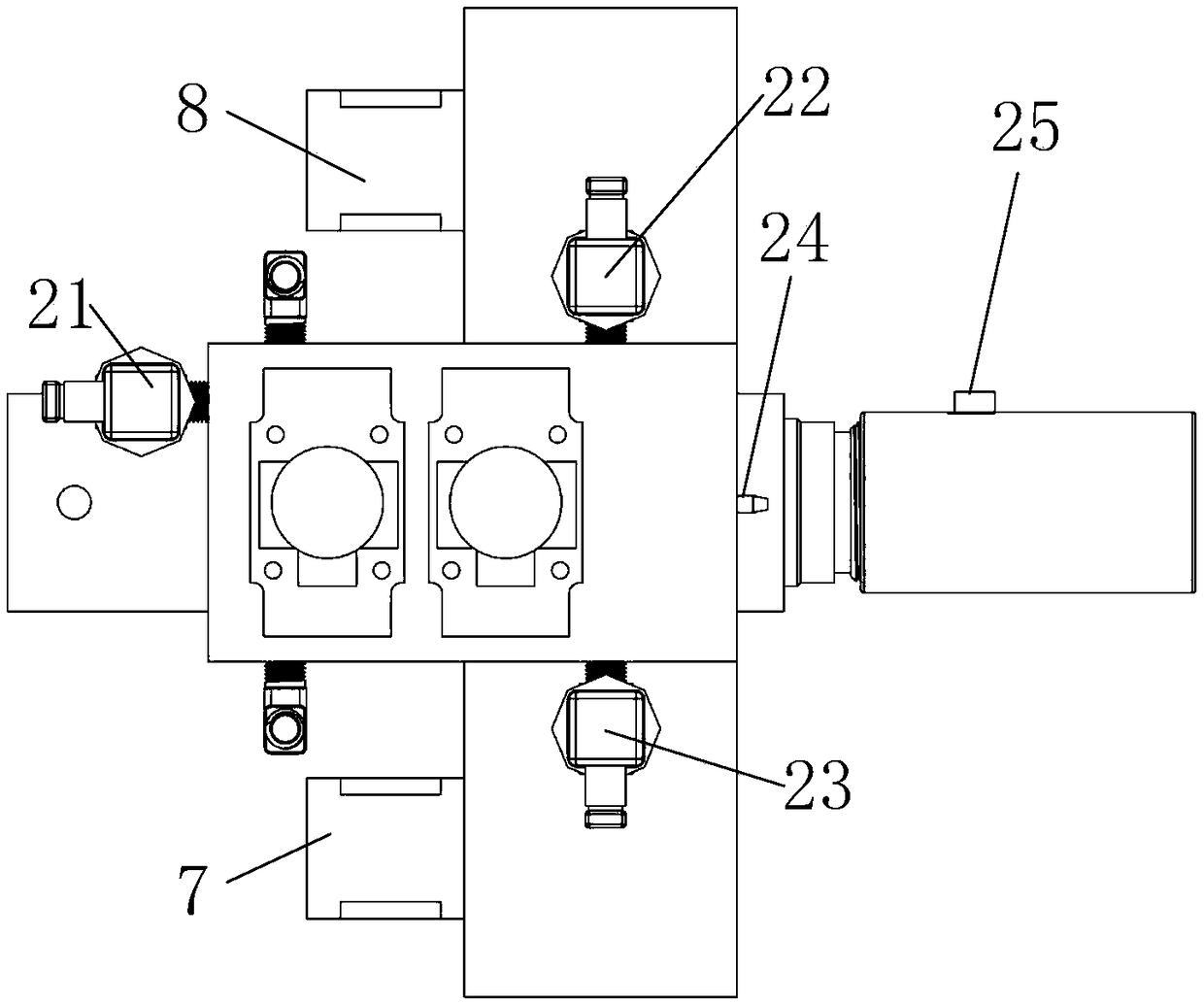

[0051] Such as figure 2 , 3 As shown in and 4, the electro-hydraulic drive part includes an excitation oil source, a single rod excitation cylinder, a connecting sleeve 4, a first servo valve 5, a second servo valve 6, a first oil pressure adjustment assembly 7 and a second oil Pressure regulator assembly 8. The single-rod excitation cylinder includes a cylinder body 9 and an excitation piston rod 10 . The cylinder body 9 and the frame form a sliding pair, and are fixed with the broaching piston rod of the broaching main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com