Viscosity modifying agent suitable for a 3D printing sulphoaluminate cement-based material

A technology for printing sulfoaluminate and viscosity modifier, which is applied in the field of viscosity modifier and cement viscosity modifier, can solve the problems of not being able to comprehensively consider and control printing time, rheological properties, and irreparable strength, etc. Improved printability, improved thixotropy, longer set times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

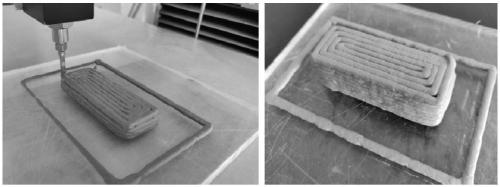

Image

Examples

Embodiment 1

[0030] A viscosity modifier suitable for 3D printing sulfoaluminate cement-based materials. In parts by weight, the viscosity modifier includes the following components: 6 parts of polyethylene glycol, 22 parts of graphene oxide, and propylene oxide 11 parts of alcohol, 12 parts of water reducing agent, 6 parts of starch, 6 parts of quartz powder, the particle size of the quartz powder is 0.5-20 μm.

Embodiment 2

[0032] A viscosity modifier suitable for 3D printing sulfoaluminate cement-based materials. In parts by weight, the viscosity modifier includes the following components: 8 parts of polyethylene glycol, 31 parts of graphene oxide, and propylene oxide 15 parts of alcohol, 14 parts of water reducing agent, 14 parts of starch, 7 parts of quartz powder, the particle size of the quartz powder is 0.5-20 μm.

Embodiment 3

[0034] A viscosity modifier suitable for 3D printing sulfoaluminate cement-based materials. In parts by weight, the viscosity modifier includes the following components: 9 parts of polyethylene glycol, 37 parts of graphene oxide, and propylene oxide 18 parts of alcohol, 18 parts of water reducing agent, 19 parts of starch, 8 parts of quartz powder, the particle size of the quartz powder is 0.5-20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com