Method for purifying gamma-cyclodextrin by utilizing cyclodextrin hydrolase

A technology of cyclodextrin and hydrolase, which is applied in the field of cyclodextrin processing, can solve the problems of flammability, toxicity, unfavorable molecule recovery, etc., and achieve the effects of simple operation, improved purity, and good application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

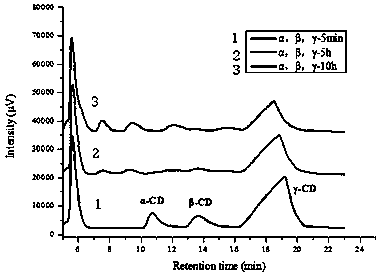

Image

Examples

Embodiment 1

[0019] Prepare 5 mL of 2% (w / v) DE13-17 maltodextrin solution with 20 mM, pH=6.0 phosphate buffer, add 0.8 U of CGTase, react at 60°C for 8 h, and inactivate with boiling water for 30 min. Using the above reaction solution as a substrate, add 0.5U cyclodextrin hydrolase, react at 80°C for 1 hour, and inactivate with boiling water for 1.5 hours after the reaction.

Embodiment 2

[0021] Use 10 mL of 50 mM, pH=6.5 10 % (w / v) soluble starch solution, pregelatinize, add 5 U of CGTase, react at 50 °C for 16 h, and inactivate with boiling water for 30 min. Using the above reaction solution as a substrate, add 2.1U cyclodextrin hydrolase and react at 70°C for 4h. After the reaction, inactivate with 5mL of 0.4M NaOH and neutralize with 0.4M hydrochloric acid solution.

Embodiment 3

[0023] Use 50mM, pH=7.5 5% (w / v) soluble starch solution 30mL, pregelatinize, add 11.7U CGTase, react at 50°C for 24h, and inactivate with boiling water for 30min. Using the above reaction solution as a substrate, add 5.3U cyclodextrin hydrolase, and react at 65°C for 12h. After the reaction, inactivate with 15mL of 1M NaOH, and neutralize the solution with 1M hydrochloric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com