Antibacterial PPR hot water pipe material and preparation method thereof

A technology of hot water pipes and antibacterial agents, applied in the field of polypropylene, can solve the problems of harmful bacteria and mold pollution, affect the health of users, and easily reproduce bacteria, etc., and achieve the effect of high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

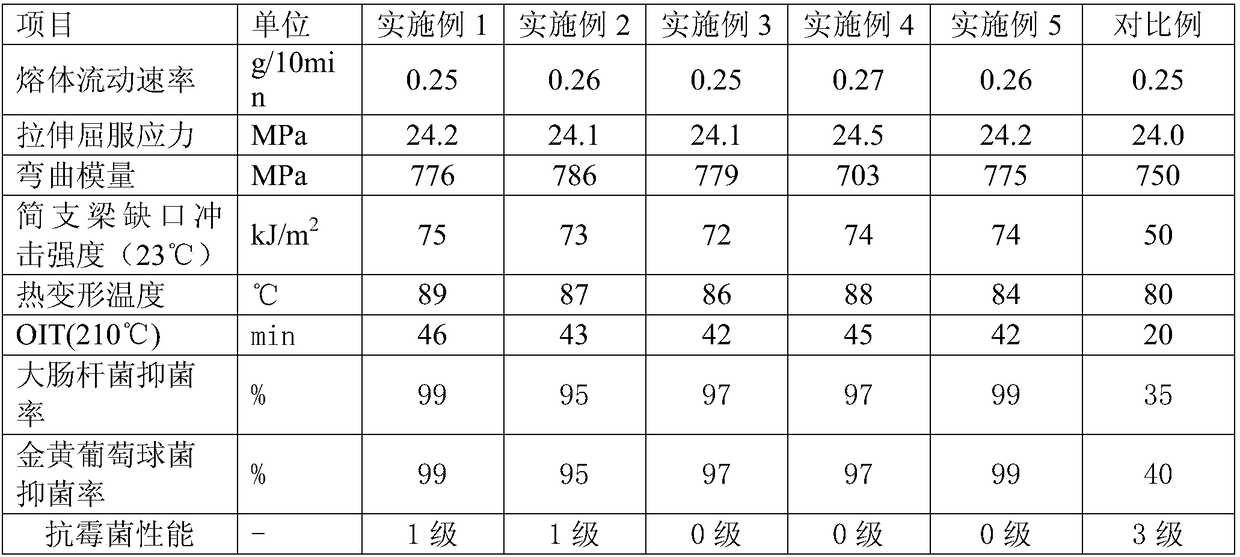

Examples

Embodiment 1

[0022] Adopt AMOCO gas-phase polymerization process, double reactor series polymerization method to produce random polypropylene: add broad-distributed main catalyst SAL (produced by Beijing Aoda Company, the source of other examples is the same) into the first reactor, and the reaction temperature is 60-70 ℃, the reaction pressure is 2-3MPa, the amount of hydrogen added is controlled at 0.35kg / h, ethylene monomer is added for copolymerization, the amount of ethylene added is 590kg / h, and the amount of polymerization is controlled at 15t / h; then enter the second reactor and close Hydrogen feed valve, the amount of ethylene added is 480kg / h, the polymerization amount is controlled at 7t / h, the reaction temperature is 70-80°C, the reaction pressure is 2-3MPa, and the random polypropylene is obtained by polymerization in the second reactor.

[0023] Take 100 parts of random polypropylene, add compounding auxiliary system (0.1 part of antioxidant PEPQ and 0.075 part of DSTDP and 0....

Embodiment 2

[0025] Adopt AMOCO gas-phase method polymerization, double-reactor series polymerization to produce random polypropylene: add broad-distributed main catalyst SAL into the first reactor, the reaction temperature is 60-70°C, the reaction pressure is 3MPa, and the amount of hydrogen added is controlled at 0.3kg / h, add ethylene monomer to carry out copolymerization, the addition of ethylene is 550kg / h, the polymerization amount is controlled at 18t / h; then enter the second reactor, close the hydrogen feed valve, the addition of ethylene is 450kg / h, the polymerization amount is controlled At 8t / h, the reaction temperature is 70-80°C, and the reaction pressure is 2MPa. Polymerize in the second reactor to obtain random polypropylene.

[0026] Get 100 parts of random polypropylene, add compounding auxiliary agent system (0.15 part of antioxidant 330, 0.075 part of antioxidant PEPQ and 0.05 part of DSTDP and 0.2 part of nano rubber compounding auxiliary system loaded with antibacterial...

Embodiment 3

[0028] AMOCO gas-phase polymerization is adopted, and double-reactor series polymerization is used to produce random polypropylene: the wide-distributed main catalyst SAL is added to the first reactor, the reaction temperature is 60-70°C, the reaction pressure is 2.5MPa, and the amount of hydrogen added is controlled at 0.4 kg / h, add ethylene monomer for copolymerization, the amount of ethylene added is 640kg / h, and the polymerization amount is controlled at 18t / h; then enter the second reactor, close the hydrogen feed valve, the amount of ethylene added is 520kg / h, the polymerization amount Controlled at 9t / h, reaction temperature 70-80°C, reaction pressure 2.3MPa, polymerize in the second reactor to obtain random polypropylene.

[0029] Get 100 parts of random polypropylene, add compounding auxiliary agent system (0.1 part of antioxidant PEPQ and 0.1 part of DSTDP and 0.3 part of nano rubber compounding auxiliary system loaded with antibacterial agent, wherein antibacterial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com