Al-Mg-Si-Cu-Mn alloy and preparation method thereof

A technology of al-mg-si-cu-mn and alloy, which is applied in the field of Al-Mg-Si-Cu-Mn alloy and its preparation, can solve the problems that cannot meet the production requirements of high-brightness electronic structural parts and produce sand holes , to achieve excellent anodic oxidation effect, high specific strength and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

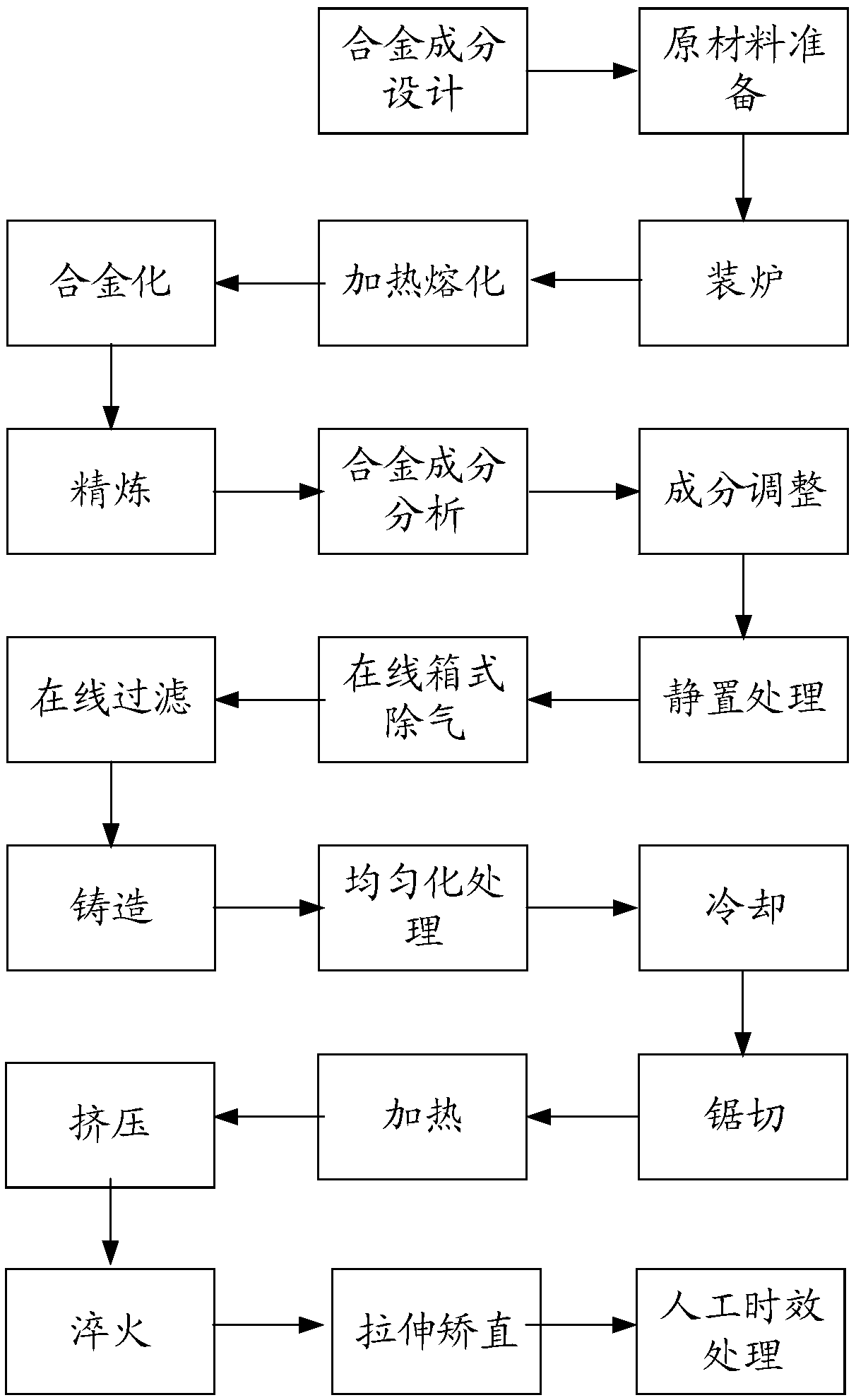

[0053] A method for preparing an Al-Mg-Si-Cu-Mn alloy provided by the present invention comprises the following steps: (1) preparing raw materials according to the above-mentioned mass percentage; (2) smelting and alloying the raw materials (3) refining the aluminum alloy liquid I, removing slag, and standing still to obtain the aluminum alloy liquid II; (4) adding a grain refiner to the aluminum alloy liquid II to obtain Aluminum alloy liquid III; (5) semi-continuous water-cooled casting of the aluminum alloy liquid III to obtain an aluminum alloy ingot A; (6) homogenization treatment and cooling to obtain an aluminum alloy ingot B; extruding and quenching to obtain an extruded aluminum alloy Alloy; (7) Artificial aging treatment to obtain alloy ingot.

[0054] Preferably, the homogenization treatment is a two-stage homogenization treatment, including: the first stage: the aluminum alloy ingot A is heated from room temperature to 530-550°C at a heating rate of 180°C-250°C / h a...

Embodiment 1-4

[0066] An Al-Mg-Si-Cu alloy described in Examples 1-4 includes the components shown in Table 1 in terms of mass percentage, wherein the total percentage of impurities is ≤0.15%, and the balance is Al.

[0067] Table 1

[0068] components

Example 1

Example 2

Example 3

Example 4

Si

0.6%

0.7%

0.55%

0.7%

Mg

0.9%

0.95%

0.85%

0.9%

mn

0.15%

0.12%

0.1%

0.18%

Cu

0.6%

0.63%

0.57%

0.48%

Ti

0.008%

0.003%

0.01%

0.012%

Mg:Si

1.5:1

1.357:1

1.545:1

1.286:1

[0069] The raw materials for preparing the above-mentioned Al-Mg-Si-Cu alloy are as follows:

[0070] Aluminum ingots: selected as aluminum ingots with a purity ≥99.9%, meeting the requirements of Al99.90 in the standard GB / T 1196-2008 "Aluminum Ingots for Remelting";

[0071] Magnesium ingot: Magnesium ingot is preferably magnesium ingot with a purity ≥ 99.95%, which meets the requirements of Mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com