A method for eliminating holes in alloy structural steel by laser deposition

A laser deposition and structural steel technology, applied in metal material coating process, coating, additive manufacturing, etc., can solve problems such as deposition holes, and achieve the effect of dense and uniform structure, improved utilization rate, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

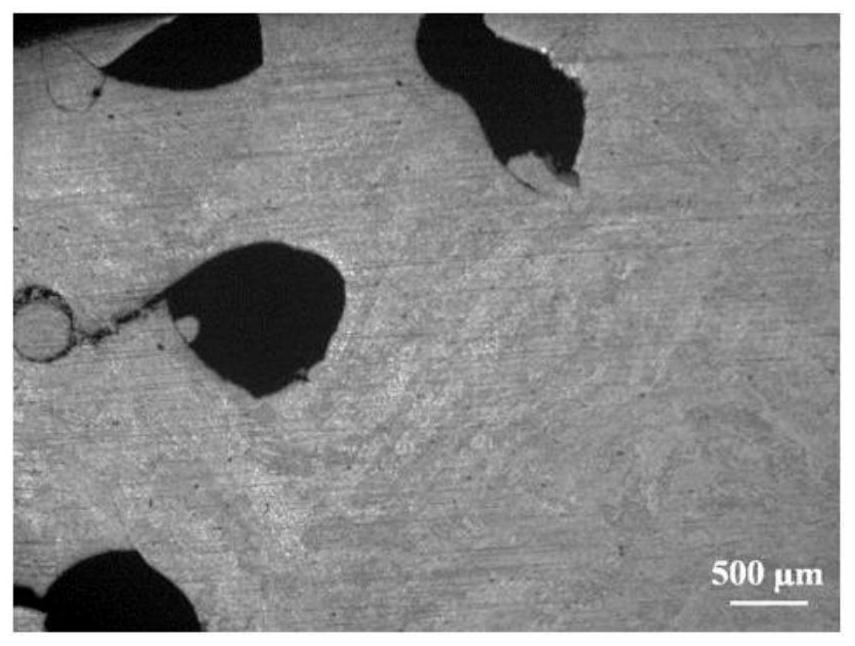

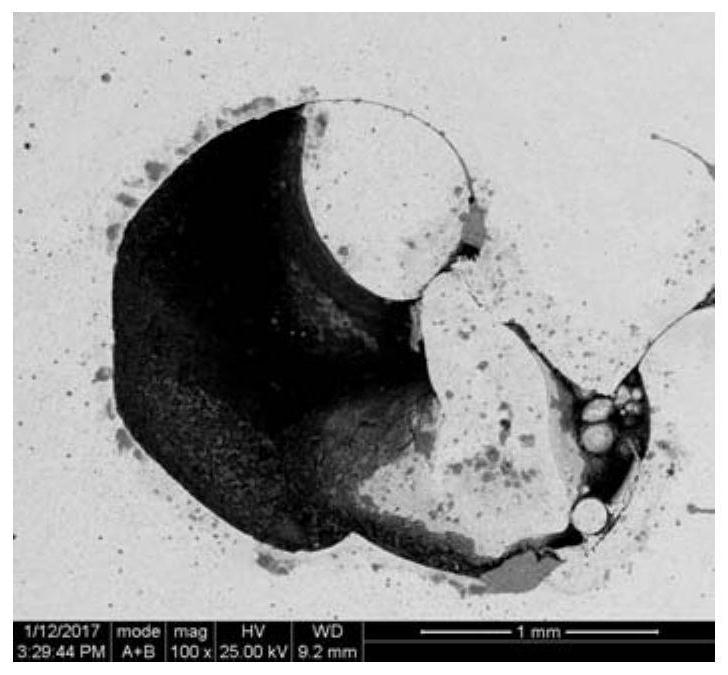

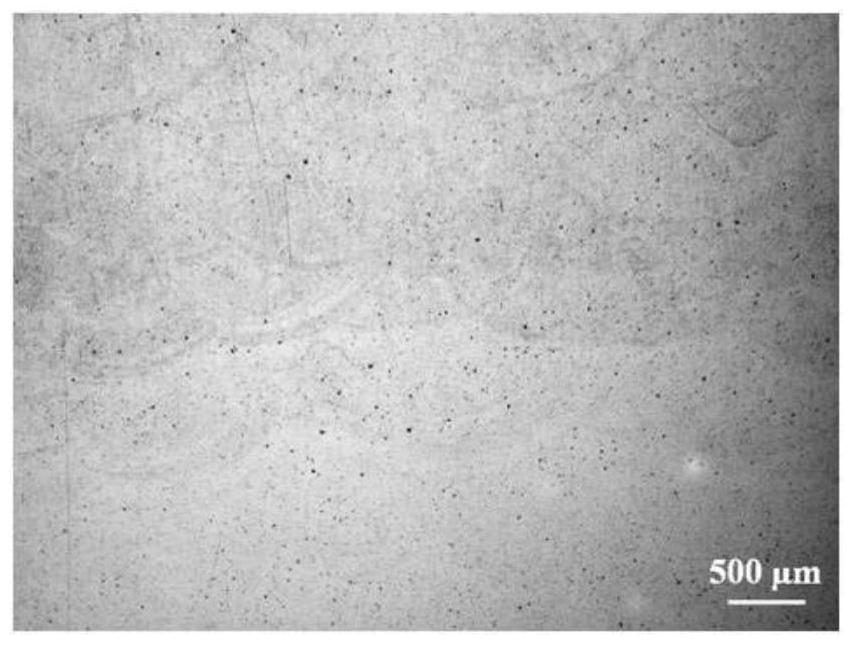

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the specific steps of the laser deposition hole elimination method for alloy structural steel are as follows:

[0032] 1. Alloy structural steel powder particle size is 100-250 mesh, sphericity ≥ 93%, oxygen content ≥ 500PPM; Ni, Cr, Nb powder particle size is 100-250 mesh, sphericity ≥ 94%, chemical composition purity 99.99 More than wt%, oxygen content ≤ 500PPM. Among them, the alloy grade of the alloy structural steel powder is 12CrNi2.

[0033] 2. Take a powder of pure Cr and mix it into the alloy steel powder at a ratio of 4wt%. Calculated by weight percentage, the ratio of Cr powder to the entire mixed alloy steel powder is 4%.

[0034] 3. Drying treatment of mixed powder: temperature 100℃×1.5h.

[0035] 4. Deposition substrate: 12CrNi2 alloy structural steel.

[0036] 5. Laser deposition vacuum glove box environment: H 2 O, O 2 ≤50PPM.

[0037] 6. Process parameters of laser deposition: continuous laser irradiation, laser power 900W, pow...

Embodiment 2

[0043] In this embodiment, the specific steps of the laser deposition hole elimination method for alloy structural steel are as follows:

[0044] 1. Alloy structural steel powder particle size is 100-250 mesh, sphericity ≥ 93%, oxygen content ≥ 500PPM; Ni, Cr, Nb powder particle size is 100-250 mesh, sphericity ≥ 94%, chemical composition purity 99.99 More than wt%, oxygen content ≤ 500PPM. Among them, the alloy grade of the alloy structural steel powder is 12CrNi2.

[0045] 2. Two kinds of powders of pure Ni and Cr are mixed into the alloy steel powder at a ratio of 1wt%, respectively. Calculated by weight percentage, the ratio of Ni and Cr powder to the whole mixed alloy steel powder is 2%.

[0046] 3. Drying treatment of mixed powder: temperature 80℃×3.0h.

[0047] 4. Deposition substrate: 12CrNi2 alloy structural steel.

[0048] 5. Laser deposition vacuum glove box environment: H 2 O, O 2 ≤50PPM.

[0049] 6. Process parameters of laser deposition: continuous laser ir...

Embodiment 3

[0053] In this embodiment, the specific steps of the laser deposition hole elimination method for alloy structural steel are as follows:

[0054] 1. Alloy structural steel powder particle size is 100-250 mesh, sphericity ≥ 93%, oxygen content ≥ 500PPM; Ni, Cr, Nb powder particle size is 100-250 mesh, sphericity ≥ 94%, chemical composition purity 99.99 More than wt%, oxygen content ≤ 500PPM. Among them, the alloy grade of the alloy structural steel powder is 12CrNi2.

[0055] 2. Three kinds of pure Ni, Cr and Nb powders are mixed into the alloy steel powder at a ratio of 1wt%, and the ratio of Cr powder to the whole mixed alloy steel powder is 3% in terms of weight percentage.

[0056] 3. Drying treatment of mixed powder: temperature 120℃×2.0h.

[0057] 4. Deposition substrate: 12CrNi2 alloy structural steel.

[0058] 5. Laser deposition vacuum glove box environment: H 2 O, O 2 ≤50PPM.

[0059] 6. Process parameters of laser deposition: continuous laser irradiation, laser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com