Ecological pretreatment process of American cotton fabrics

A pretreatment and process technology, applied in the field of ecological pretreatment of American cotton fabrics, can solve the problems of large damage to cotton fibers, heavy burden of sewage treatment, high energy consumption, and high water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

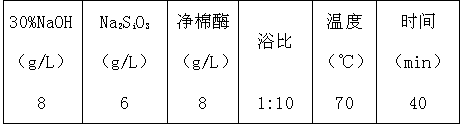

[0014] The specific pre-treatment process of the present invention is as follows: cotton grey cloth → atmospheric air plasma pretreatment → ultrasonic biological enzyme desizing → ultrasonic cotton cleaning enzyme combined with hydrogen peroxide bleaching → hot water washing → cold water washing → drying.

[0015] 1. Atmospheric air plasma pretreatment: pre-baking temperature 80±10℃; in the plasma discharge system, ceramic tube and quartz tube composite components are used to generate composite plasma of different intensities, and the discharge time is 2.2 min~2.6min; The discharge power is 25 KW~30KW.

[0016] The cotton fabric pretreated by atmospheric air plasma can omit the de-boiling process in the pre-treatment and directly carry out the water washing process, and then continue the treatment according to the traditional oxygen bleaching process. This new pre-treatment process can not only achieve the effect of traditional pre-treatment processing, but also eliminates the pre-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com